Cold damage prevention dredging agent for low-temperature-resistant oil reservoir

A dredging agent and low temperature-resistant technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as blockage of oil production screens, retention of fine pores in heterogeneous rock formations, and inability to implement stimulation operations in oil fields. Achieve the effect of improving oil recovery and avoiding the problem of blockage and production reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

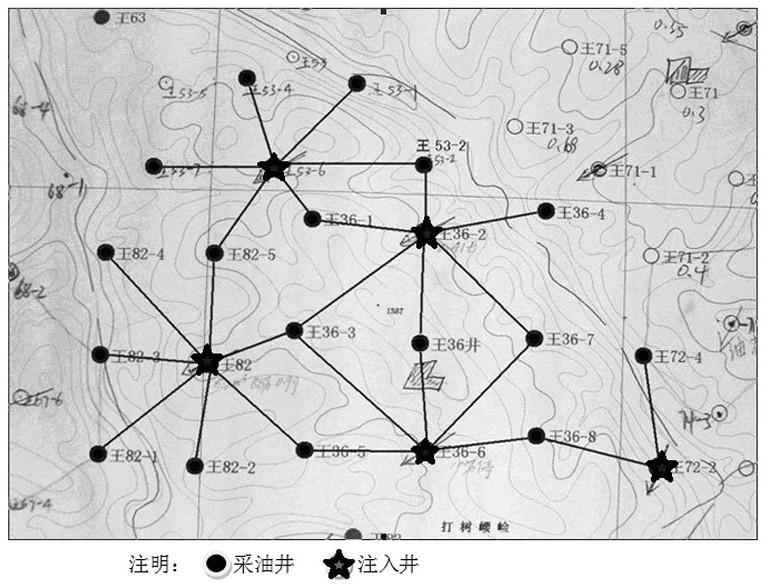

[0051] Embodiment 1: The present invention adopts the mode of one injection and multiple extractions, and the specific injection well group and the distribution map of benefited well positions refer to figure 1 :

[0052] Injection well group:

[0053] (Wang 82) (Wang 36-6) (Wang 72-2) (Wang 36-2) (53-6) Total injection wells: 5

[0054] Unilateral benefit well:

[0055] (King 53-1) (King 53-4) (King 53-7) (King 36-4) (King 82-1) (King 82-2)

[0056] (King 82-3) (King 82-4) (King 72-4) Unilateral total: 9 wells

[0057] Bilateral benefits:

[0058] (King 53-2) (King 82-5) (King 36) (King 36-1) (King 36-3) (King 36-5

[0059] (King 36-7) (King 36-8) Bilateral total: 8 wells

[0060] Implementation of dredging plan formulation:

[0061] According to the actual situation that the oil production block is a low-permeability oil layer, combined with the geological data provided by the oil production plant, as well as the production account and other data, after communicating ...

Embodiment 2

[0080] Embodiment 2, the present invention adopts the mode of single well injection / reversal:

[0081] According to the actual situation of each oil production well, combined with the geological data provided by the oil production plant, as well as production ledger and other data. After communicating with the technical department of the oil production plant, the specific implementation plan is formulated as follows after joint research and judgment.

[0082] The total injection volume of the designed dredging agent:

[0083] (1) Calculated according to the well depth of the production well, the length of the production section, and the dredging sweep radius.

[0084] (2) The total injection volume *0.25~3 is the oil layer saturation amount, and the saturation amount *0.5~2 is the loss amount of the heterogeneous oil layer.

[0085] (3) Reservoir saturation amount + heterogeneous oil layer loss amount = design injection total amount.

[0086] The implementation dredging pla...

Embodiment 3

[0103] Embodiment 3, high water cut well or low productivity well

[0104] As the years of oilfield exploitation increase, such as the increase in the number of high water-cut oil wells and low-production oil wells, it is also called aging wells.

[0105] Most of the oil layers in the oil production block are plane heterogeneous oil layers. With the extension of the production time of the oil production well, the deposition of heavy components of crude oil is more serious, and at the same time, the adsorption force of organic blockages on the oil flow channels is enhanced, which leads to water leakage in the large pores near the wellbore, and blockage or retention in the micro pores The problem.

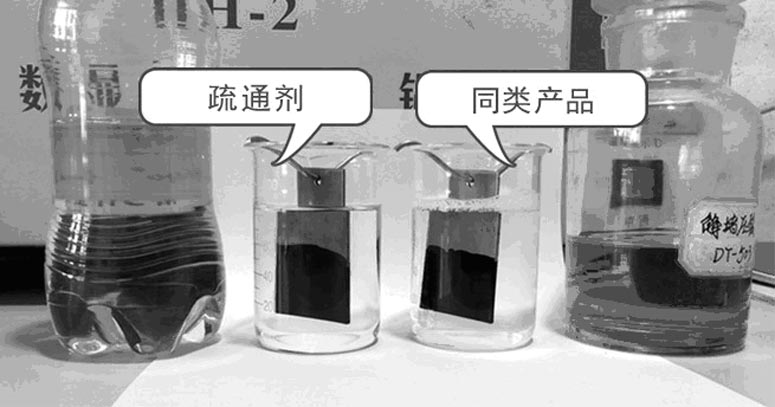

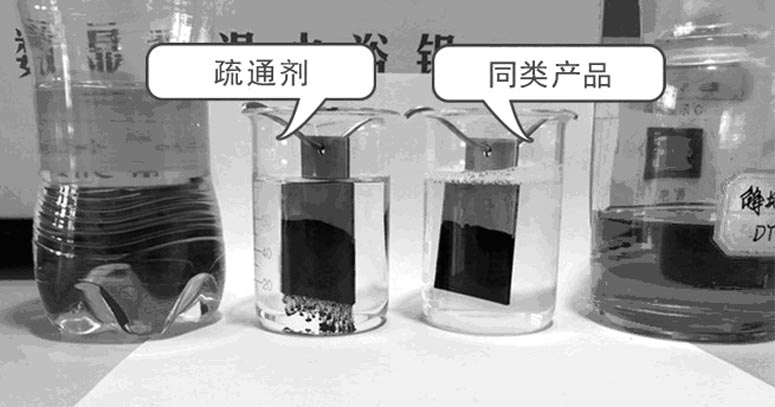

[0106] According to the content of crude oil components in different oil production blocks, such as colloid, asphaltene, wax, etc., different proportions of dredging agent formulas are formulated to ensure the purpose of increasing production after dredging. The dredging agent is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com