Rotation planting method of rice and winter wheat in saline-alkali land

A technology of crop rotation and winter wheat, applied in the fields of land preparation, chemical instruments and methods, rice cultivation, etc., can solve the problems of many cations, difficult to promote seedlings, and low soil fertility, and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

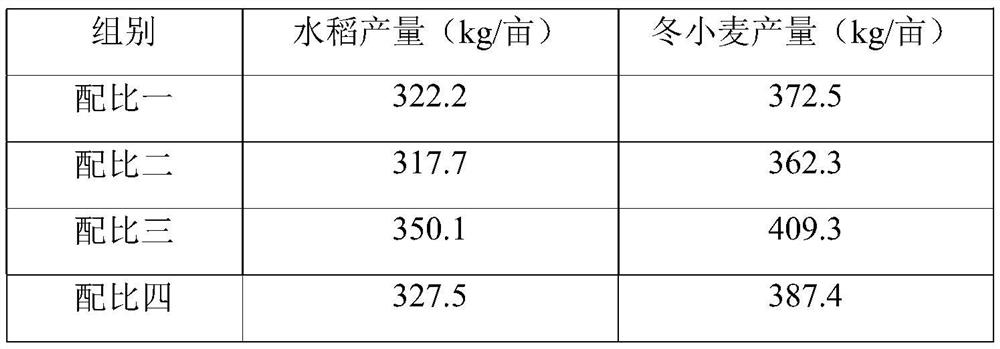

[0043] Example 1 Carrying out rice and winter wheat crop rotation in a salt-alkali land with a salt content of 4.1‰ and a pH of 8.1 in Qingdao

[0044] (1) Different proportions of soil directional conditioners

[0045] Proportion 1: Phosphogypsum 55%, weathered coal 10%, humic acid 20%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0046] Proportion 2: phosphogypsum 50%, weathered coal 15%, humic acid 20%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0047] Proportion three: phosphogypsum 50%, weathered coal 10%, humic acid 25%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0048] Proportion 4: Phosphogypsum 50%, weathered coal 10%, humic acid 20%, biogas residue 10%, woody peat 5%, potassium sulfate 5%;

[0049] Proportion 5: phosphogypsum 50%, weathered coal 10%, humic acid 20%, biogas residue 5%, woody peat 10%, potassium sulfate 5%.

[0050] (2) Specific steps

[0051] In the first year, 18 days before rotary tillage and soil preparation, choose to...

Embodiment 2

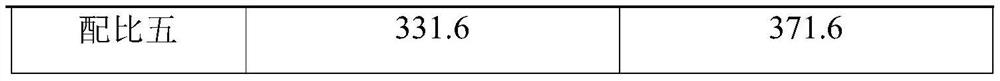

[0056] Example 2 Carrying out rice and winter wheat rotation in a saline soil with a salt content of 3.8‰ and a pH of 7.9 in Qingdao

[0057] (1) Different proportions of soil directional conditioners

[0058] Proportion 1: Phosphogypsum 55%, weathered coal 10%, humic acid 20%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0059] Proportion 2: phosphogypsum 50%, weathered coal 15%, humic acid 20%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0060] Proportion three: phosphogypsum 50%, weathered coal 10%, humic acid 25%, biogas residue 5%, woody peat 5%, potassium sulfate 5%;

[0061] Proportion 4: Phosphogypsum 50%, weathered coal 10%, humic acid 20%, biogas residue 10%, woody peat 5%, potassium sulfate 5%;

[0062] Proportion 5: phosphogypsum 50%, weathered coal 10%, humic acid 20%, biogas residue 5%, woody peat 10%, potassium sulfate 5%.

[0063] (2) Specific steps

[0064] In the first year, 15 days before rotary tillage and soil preparation, choose to spray the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com