A wood structure connecting tenon manufacturing process

A processing technology and wood structure technology, which is applied in the field of wood structure connection mortise and processing technology, can solve the problems that wooden materials cannot be cut at one time, lack of friction, and reduce the service life of cutting machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

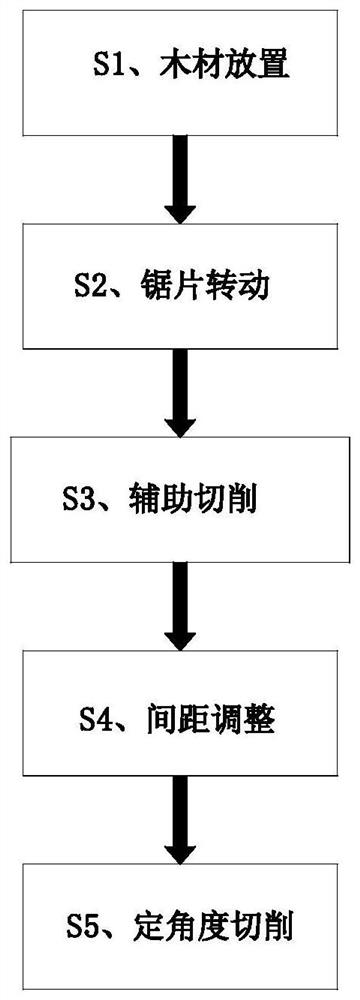

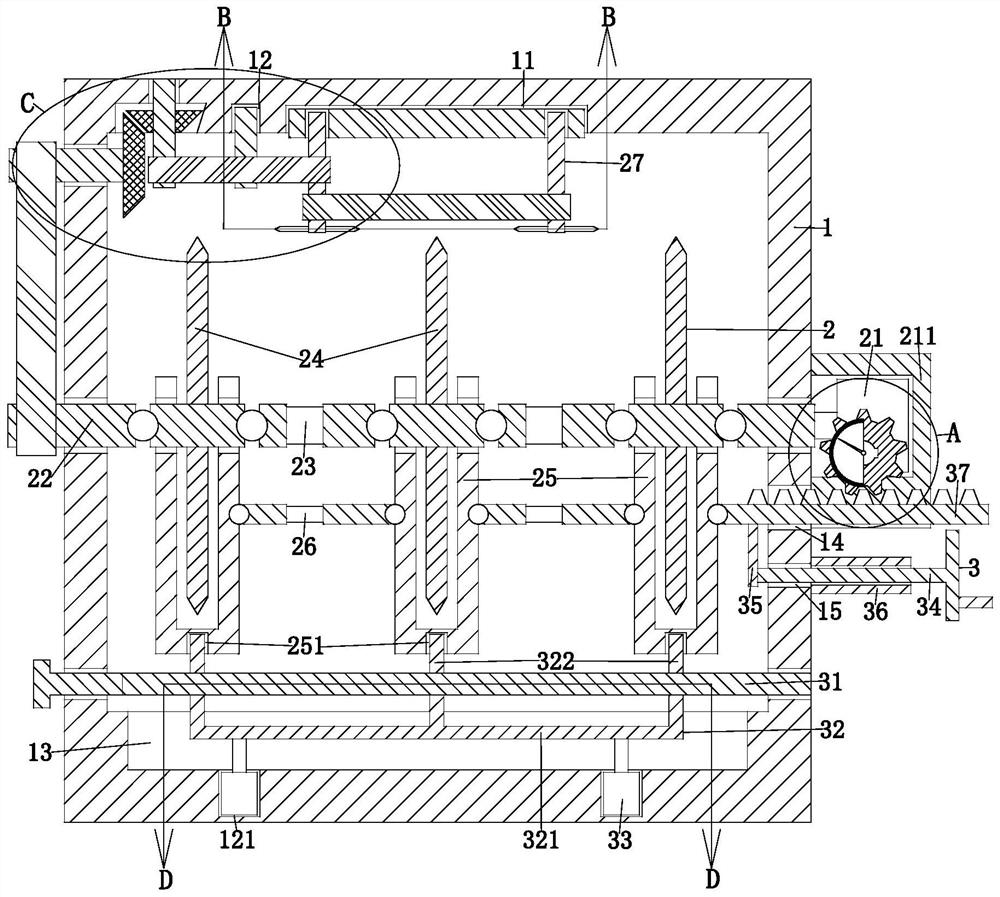

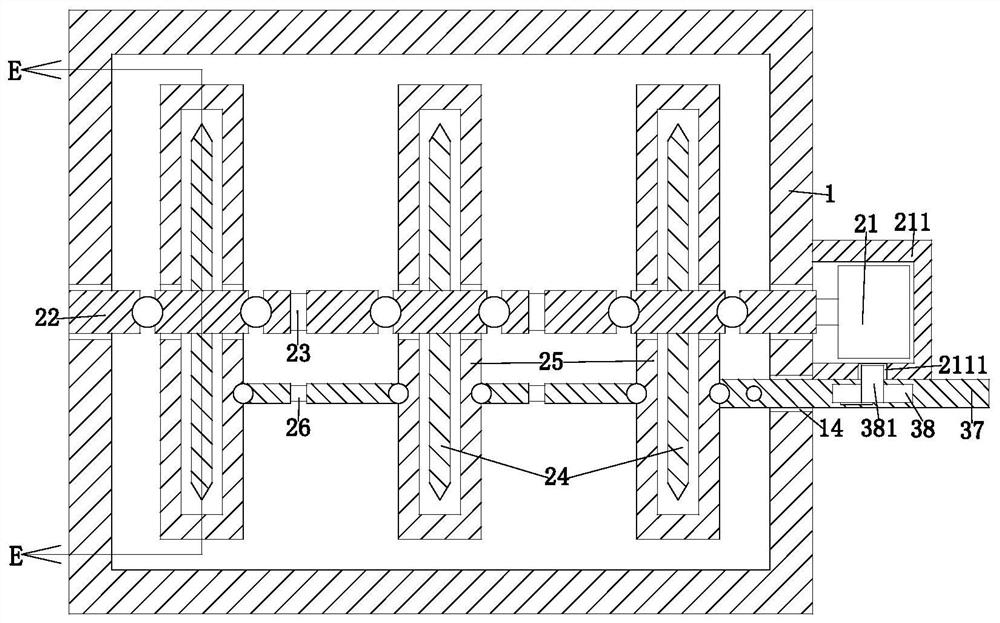

[0040] like Figure 1 to Figure 9 The shown manufacturing process of tenon for wood structure connection is mainly completed by the cooperation of a tenon manufacturing and processing equipment. The tenon manufacturing and processing equipment includes a processing shell 1, a cutting unit 2 and an adjustment unit 3. There is a square chute 11, a linkage groove 13 is opened at the lower end of the processing casing 1, the cutting unit 2 is arranged on the inner wall of the middle part of the processing casing 1, and the adjusting unit 3 is arranged in the linkage groove 13, wherein:

[0041] The upper end of the processing shell 1 is provided with a square chute 11, the left side of the upper end of the machining shell 1 is provided with a transverse c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com