Excess material processing device for polymethyl methacrylate processing

A technology of plexiglass and processing equipment, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problems such as the reduction of plexiglass cracking efficiency, and achieve the effect of improving cracking efficiency and increasing dust suppression area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

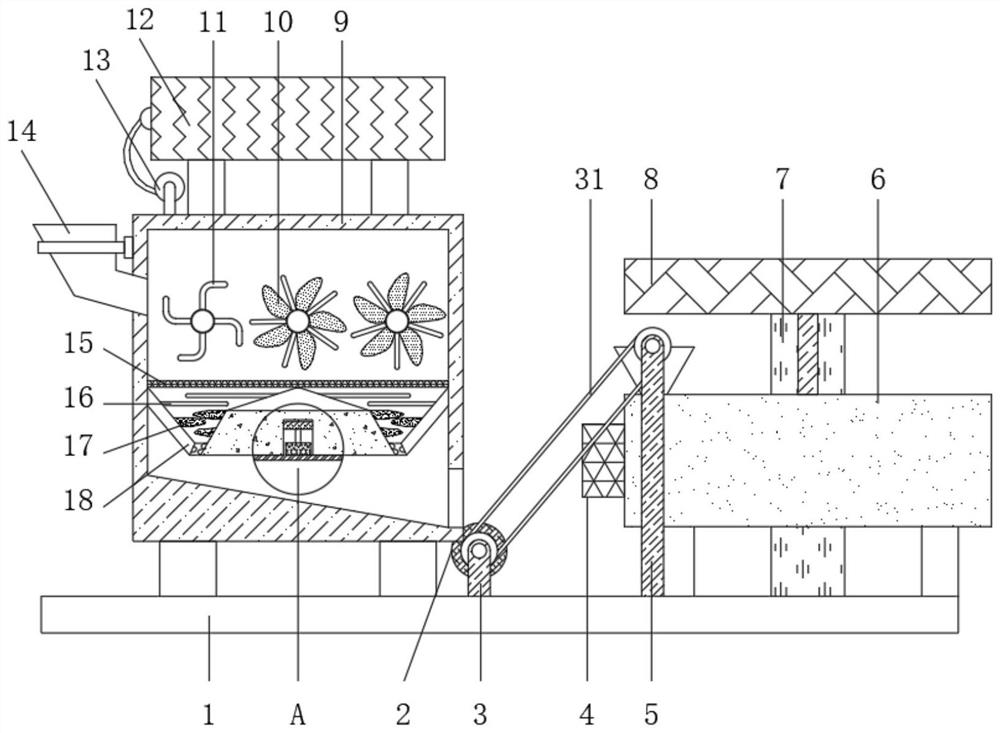

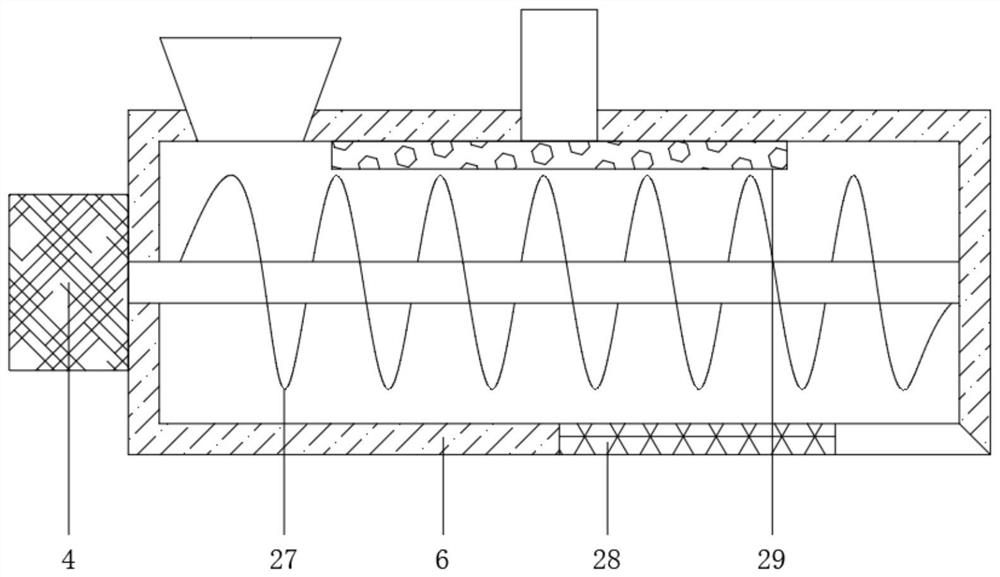

[0028] refer to Figure 1-5 , a kind of residual material treatment device for plexiglass processing, comprising a bottom plate 1, a box body 9 is fixedly installed on one side of the top outer wall of the bottom plate 1 through a bracket, and a first side plate 3 and a second side plate 3 are fixedly installed at both ends of the top outer wall of the bottom plate 1 The side plate 5, the other side of the top outer wall of the bottom plate 1 is fixedly installed with a cleaning cylinder 6 through a bracket, and the other side of the top outer wall of the bottom plate 1 is fixedly installed with a third side plate 7, the third side plate 7 is located at the upper end of the cleaning cylinder 6, and the box body 9 The outer wall of the top end is fixedly equipped with a crushing groove 12 through a bracket, the upper end of the outer wall of one side of the box body 9 is fixedly installed with a feed hopper 14 through a socket, and the outer wall of one end of the box body 9 is ...

Embodiment 2

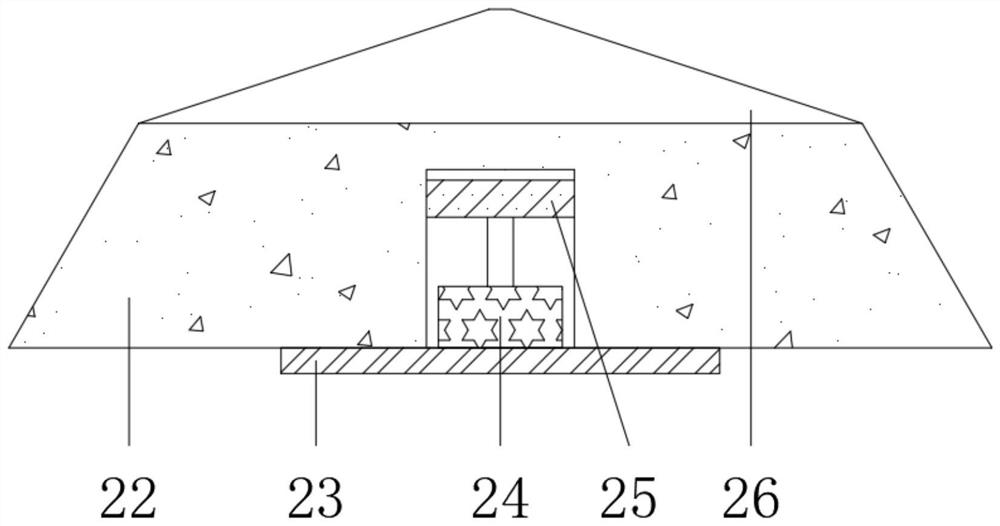

[0038] refer to Image 6 , a processing device for residual materials used in plexiglass processing, further, a dust suppression frame 30 is fixedly installed at the lower end of the outer wall of one side of the box body 9, and the inner wall at the top of the dust suppression frame 30 is wave-shaped, and the dust suppression frame 30 is located at the outlet of the box body 9 upper end.

[0039] Working principle: the dust suppression frame 30 is located at the upper end of the outlet of the box body 9 to suppress the dust from floating in the air when the plexiglass scraps are discharged, and the inner wall at the top of the dust suppression frame 30 is wave-shaped to increase the dust suppression area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com