Electric instructional car transmission system

A technology of electric coaching vehicle and transmission system, which is applied in vehicle components, control devices, transportation and packaging, etc., and can solve the problem of difficult to use engine and multi-speed transmission transmission system, pure electric vehicles have not been widely promoted, transmission shaft alignment, etc. Problems such as difficulty in assembling in the middle, achieve the effect of low production cost, high centering precision, and low difficulty in assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

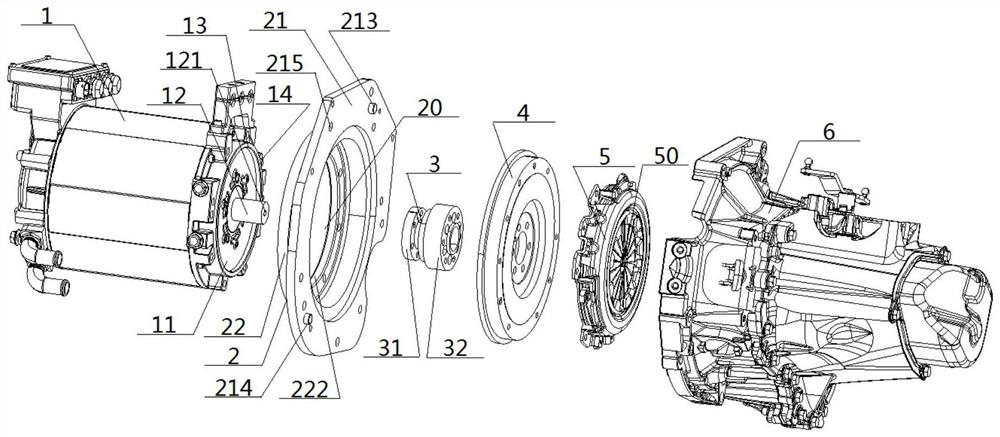

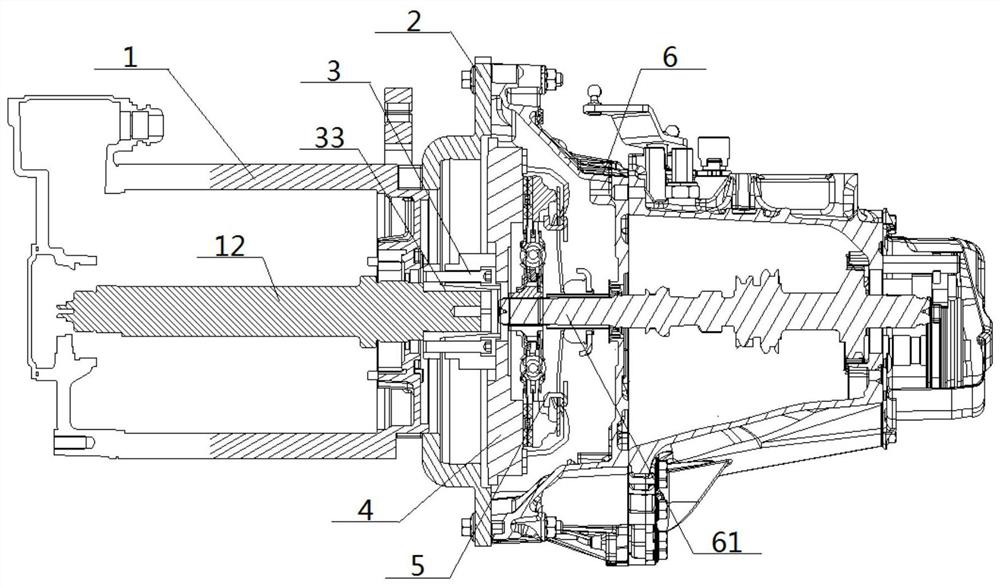

[0056] see figure 1 — Figure 13 , a transmission system for an electric coach, comprising a flywheel 4, a clutch assembly 5 and a gearbox 6 arranged in sequence, and a gearbox shaft 61 is arranged in the gearbox 6; the transmission system for an electric coach also includes a motor 1, Connecting the flange 2 and the coupling 3, the right end of the motor 1 is provided with the outer end surface 11 of the motor and the output shaft 12 protruding in the middle. The middle part of the flange 2 is provided with a flange cavity 20; the outer end surface 11 of the motor is centered and connected with the left end of the connecting flange 2, and the right end of the connecting flange 2 is centered and connected with the left end of the gearbox 6. The output shaft 12 is connected through The coupling 3 is centeredly connected with the left end of the flywheel 4, and the right end of the flywheel 4 is centeredly connected with the clutch assembly 5. The left end of the first shaft 61...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] see Figure 4 and Figure 5 , the clutch assembly 5 includes a driven plate 51 and a pressure plate 52, the middle part of the driven plate 51 is provided with a slave spline hole 511, the middle part of the pressure plate 52 is provided with a shaft hole 521, and a shaft hole 521 is coaxially connected with the secondary spline hole 511 to form a spline hole 50; on the plate surface of the pressure plate 52, there are a plurality of connecting wheels correspondingly connected with the wheel connecting hole 521 around the position of the shaft hole 521 Hole 53.

[0060] When assembling, insert the thinner end of the tooling pin 7 into the inner shaft hole 121 in the middle of the output shaft 12, then put the driven plate 51 and the pressure plate 52 on the tooling pin 7 in sequence, and then tighten the pressure plate 52 bolts, and then take out the tooling pin 7 to ensure that the secondary spli...

Embodiment 3

[0062] Basic content is the same as embodiment 1, the difference is:

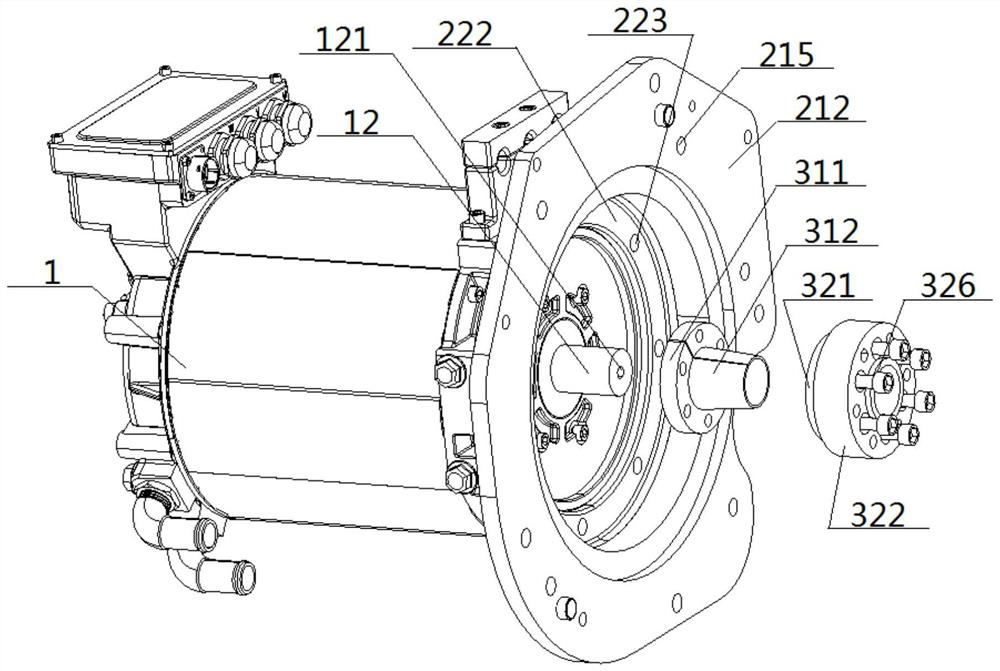

[0063] see Figure 8 — Figure 11 , the output shaft 12 is a cylindrical structure with equal diameter, the coupling 3 includes an inner coupling 31 and an outer coupling 32, the inner coupling 31 includes an inner ring seat 311 and an inner cylinder 312, the inner The cylinder 312 is a frustum of conical structure with wide left and narrow right. The inner cylinder 312 is provided with an inner cylinder cavity 313. The inner ring seat 311 is provided with an inner ring seat cavity 314 communicating with the inner cylinder body cavity 313. The inner ring seat 311 A plurality of inner ring connection holes 315 are opened around the inner cylinder 312 on the seat surface of the inner cylinder, and the inner cavity wall of the inner cylinder cavity 313 is nested with the side circumference of the output shaft 12; the outer coupler 32 includes an outer left ring seat 321 and the outer right ring seat 322, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com