Method for preparing impact-resistant steel part by utilizing phase change speed difference

A speed difference and impact-resistant technology, which is applied in the field of preparing impact-resistant steel parts by using the phase change speed difference, can solve the problems of high manufacturing cost, long carburizing cycle and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In the embodiment of the present invention, taking bearing steel parts as an example, a method for preparing bearing steel parts is provided, including the following steps:

[0075] Step 1, austenitizing the bearing steel parts: heating the bearing steel parts to T1 temperature, and keeping it warm for 0.5h-1h;

[0076] Step 2, reduce the surface temperature of bearing steel parts to T2 temperature: Quench the parts to Ms temperature, that is, in a salt bath furnace at T2 temperature below the martensitic transformation start temperature, after a short time isothermal t1 time, ensure that the surface layer The temperature is lowered to T2 temperature, and the heart temperature is not lower than Ms temperature;

[0077]Step 3, transfer the bearing steel parts to a salt bath furnace with a temperature of T3 for isothermal treatment, so that the surface and core of the bearing steel parts undergo bainite transformation, and the isothermal time is t2; at this time, because ...

Embodiment 1

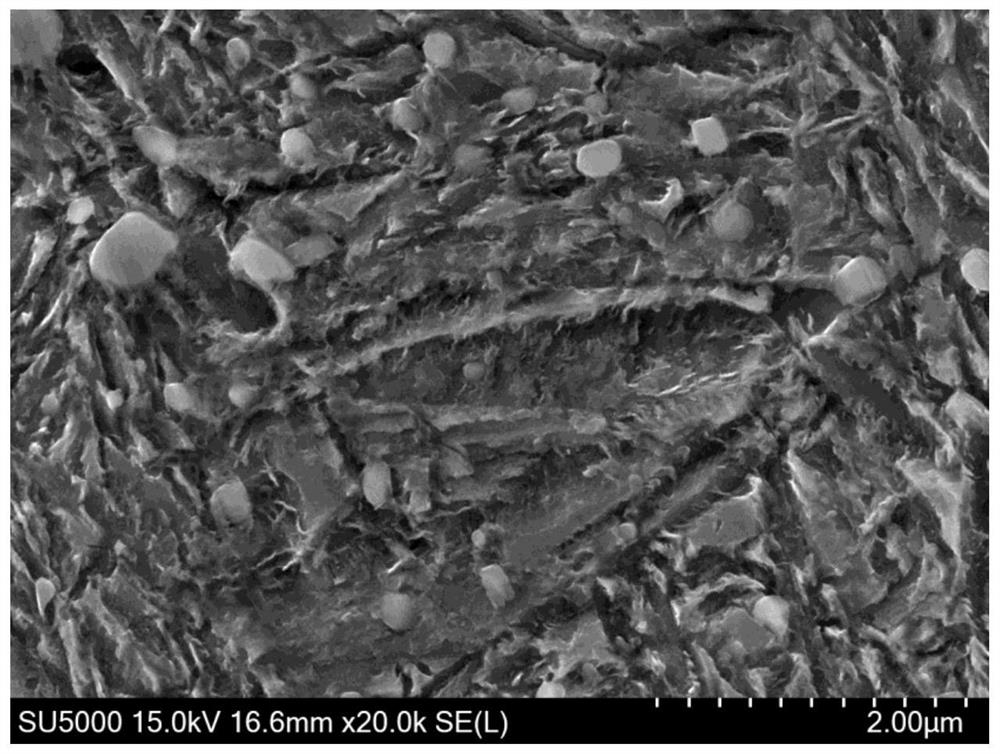

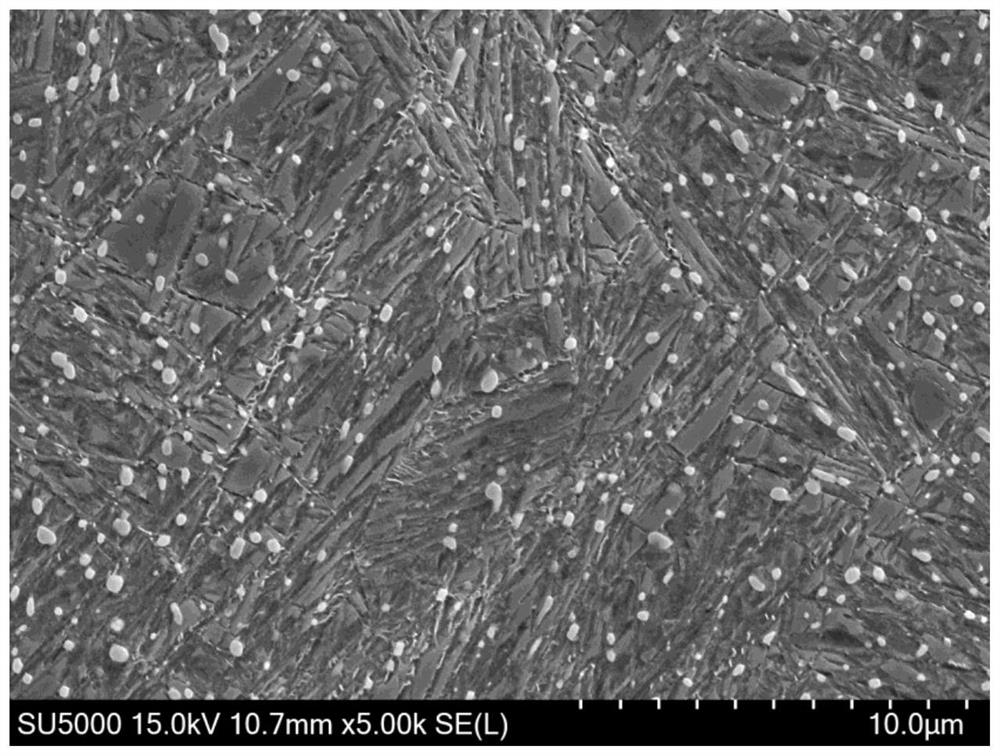

[0084] A high-carbon chromium bearing steel is used, the main chemical composition mass percentage is, C: 0.92, Si: 1.51, Mn: 1.20, Cr: 1.53, Mo: 0.38, Ni: 2.40. After spheroidizing and annealing the bearing steel, it is processed into bearing parts, and the wall thickness of the bearing ring is 72mm. The Ms temperature of the material is 165°C. Heat the bearing parts to 840°C for 30 minutes, put them in a salt bath furnace at 155°C for 10 seconds, take them out after the temperature at 6mm below the surface has dropped to 155°C, put them in a salt bath furnace at 200°C for 7 hours, then When the bainite content of the surface layer reaches 75%, and the bainite content of the core reaches 40%, take it out and cool it to room temperature, and finally keep it in a furnace at 190°C for 1 hour for tempering treatment. refer to figure 1 The surface structure diagram of the bearing steel and figure 2 In the structure diagram of the core of the bearing steel shown, the retained a...

Embodiment 2

[0087] A high-carbon chromium bearing steel is used, the main chemical composition mass percentage is, C: 0.98, Si: 0.55, Mn: 0.85, Cr: 1.52, Al: 0.08. After spheroidizing and annealing the bearing steel, it is processed into bearing parts, and the wall thickness of the bearing ring is 35mm. The Ms temperature of the material was 192°C. Heat the bearing parts to 845°C for 40 minutes, put them in a salt bath furnace at 170°C for 5 seconds, take them out after the temperature at 8mm below the surface has dropped to 170°C, put them in a salt bath furnace at 220°C for 1 hour, then When the bainite content of the surface layer reaches 73%, the bainite content of the core reaches 52%, take it out and cool it to room temperature, and finally keep it in a furnace at 170°C for 2 hours for tempering treatment. In the final structure, the retained austenite content in the surface layer is 5%, and the retained austenite content in the core is 26%. After treatment by this method, the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com