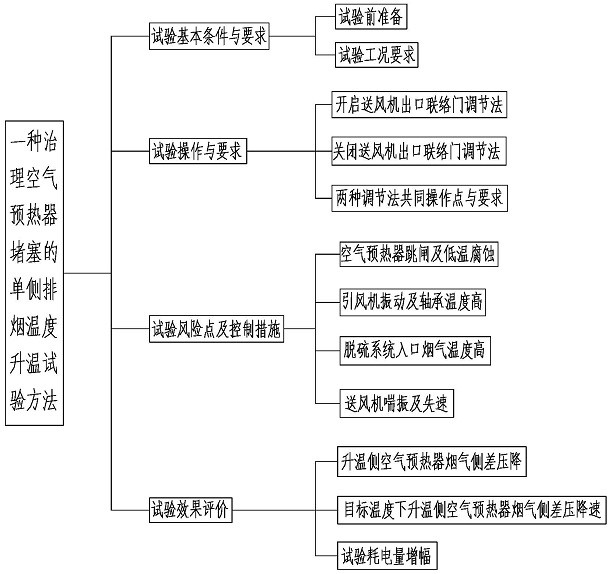

A single-side exhaust gas temperature rise test method to control the blockage of air preheater

An air preheater and test method technology, which is applied in the testing of machine/structural components, combustion methods, instruments, etc., can solve the problems in the selection of operating parameters, the treatment effect is difficult to be guaranteed, and the blockage of the air preheater cannot be solved in time. and other problems to achieve the effect of improving the level of safe and economic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0038] Example.

[0039] Unit #3 (330MW) of a coal-fired power generation company is equipped with a subcritical natural circulation boiler produced by Shanghai Boiler Factory with the technology imported from CE Company of the United States. The model is SG1025 / 17.53-M842. It adopts a single furnace four-corner tangential combustion method, equipped with a warehouse-type steel ball mill pulverizing system, adopts five-layer burners, separates the flue baffle to adjust the reheated steam temperature, and controls the superheated steam temperature through primary and secondary water spraying, and balances ventilation. All-steel structure, semi-outdoor island layout, solid-state mechanical slag discharge, Junker type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com