LED based on patterned substrate and preparation method thereof

A patterned substrate and sapphire substrate technology, applied in the field of biosensors, can solve the problems of low luminous efficiency of LEDs, and achieve the effects of simple process flow, stable processing technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing an LED based on a patterned substrate, comprising the following steps:

[0033] (1) Design an LED with a nano-pattern multilayer structure through computer software;

[0034] (2) Deposit a layer of sapphire substrate and polish it on both sides;

[0035] (3) InGaN / GaN multiple quantum wells were grown on sapphire substrates by metal-organic chemical vapor deposition;

[0036] (4) Using the molecular beam epitaxy growth method, an ordered two-dimensional structure of Ag and Si is prepared on the surface of the quantum well, and a patterned multilayer hyperbolic metamaterial is etched.

Embodiment

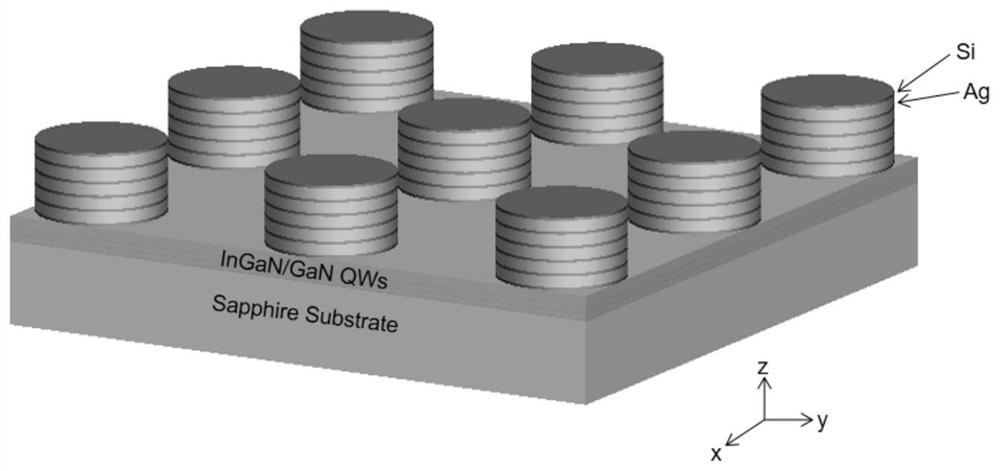

[0038] figure 1 It is a schematic diagram of an LED structure based on a patterned substrate of the present invention. As shown in the figure, the structure of the present invention from bottom to top includes a sapphire substrate with a thickness of 100nm, and three layers of InGaN / GaN layers are superimposed on the sapphire substrate, wherein each layer of InGaN / GaN layer consists of a 2nm thick InGaN layer and a 10nm-thick GaN layer on the upper layer; then a 10nm-thick GaN barrier layer is stacked on the uppermost GaN layer; and then 5 layers of Ag / Si layers are stacked on the barrier layer, wherein each layer of Ag / Si The layer consists of a 3nm thick Si layer on the lower layer and a 20nm thick Ag layer on the upper layer; finally a 5nm Si layer is superimposed on top of the uppermost Ag layer as a surface protection layer.

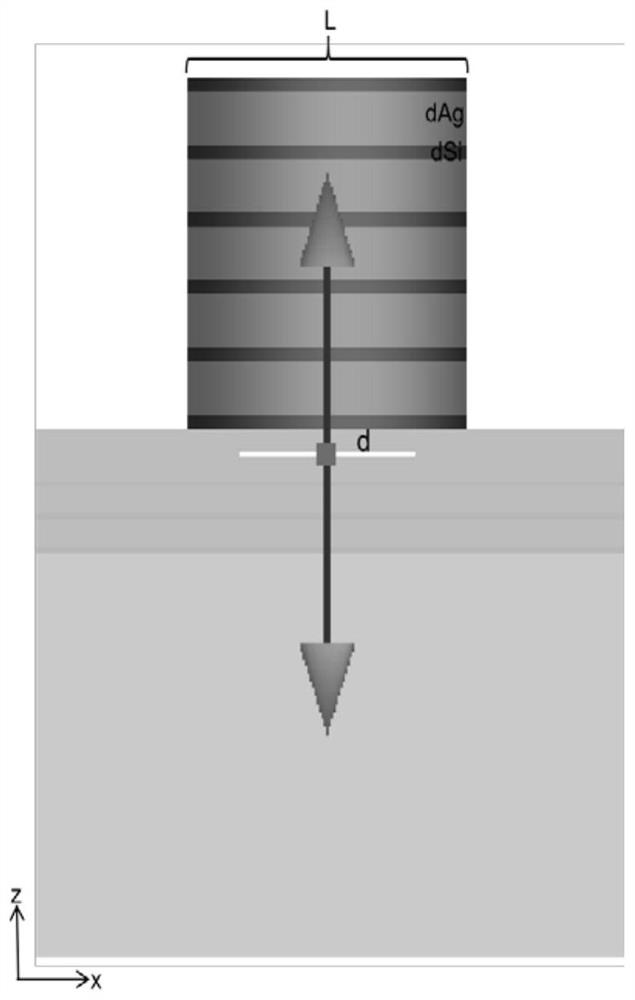

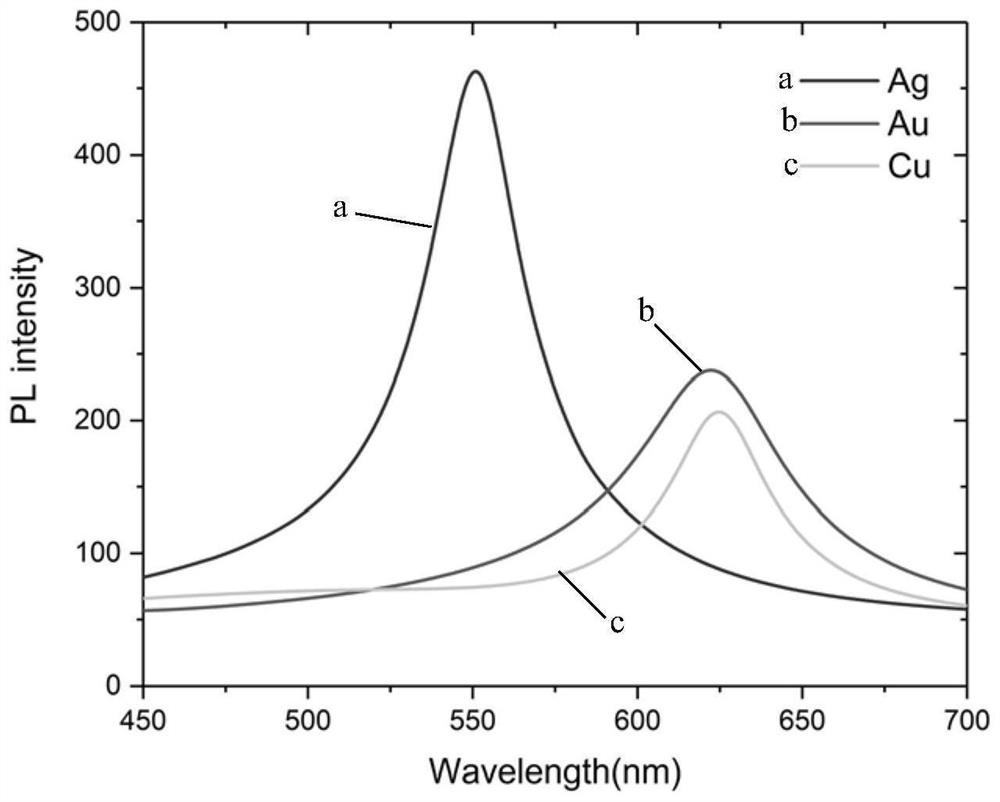

[0039] figure 2 It is a schematic diagram of the two-dimensional LED structure of the present invention. As the emission wavelength approaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com