Preparation method of mxene/cnt ion-type electrochemical actuator, prepared actuator and application

An electrochemical and driver technology, applied in the field of materials science, can solve problems such as affecting the conductivity of the electrode layer, poor film formation, reducing the driving performance of the driver, etc., to reduce the response time, increase the accumulation, improve the electronic conduction and mechanical properties. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

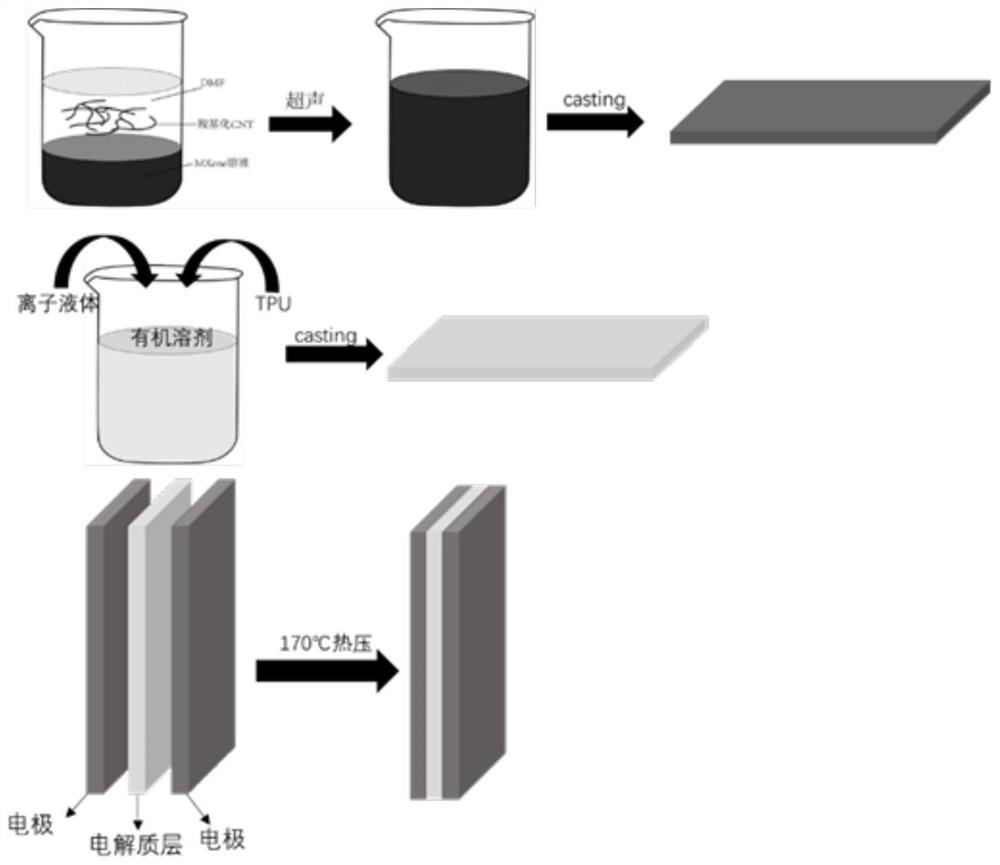

[0057] Preparation of MXene / CNT Ionic Electrochemical Actuators

[0058] (1) Weigh high-purity carboxylated single-walled carbon nanotubes (CNTs), absorb the MXene solution with a pipette gun, mix, add (nitrogen, nitrogen-dimethylformamide) DMF, and ultrasonicate for 60 minutes in an ice bath to form MXene / CNT dispersion. Among them, CNT and Ti 3 C 2 T x The concentration of solute is 8mg / ml, Ti 3 C 2 T x The mass ratio of solute and CNT is 3:1, and the concentration of MXene solution is 10mg / mL; The purity of high-purity carboxylated single-wall carbon nanotube is 90%, and diameter is 1nm, and the volume of MXene solution is 6mL in the present embodiment, MXene The solvent of the solution is deionized water, Ti in the MXene solution 3 C 2 T x The mass of solute is 60 mg, that of CNT is 20 mg, and that of DMF is 4 mL.

[0059] (2) Drop 2mL of PEDOT:PSS (PH1000) solution on the substrate, heat it on a heating platform at 50°C to form a PEDOT:PSS transparent film, the...

Embodiment 2

[0063] Preparation of MXene / CNT Ionic Electrochemical Actuators

[0064] (1) Weigh high-purity carboxylated single-walled carbon nanotubes (CNTs), draw MXene solution with a pipette gun, mix, add (nitrogen, nitrogen-dimethylformamide) DMF, and ultrasonicate for 80 minutes in an ice bath to form MXene / CNT dispersion. Among them, CNT and Ti 3 C 2 T x The concentration of solute in DMF is 8mg / ml, Ti 3 C 2 T x The mass ratio of solute to CNT is 2:1, the concentration of MXene solution is 10mg / mL; the purity of high-purity carboxylated single-walled carbon nanotubes is 90%, and the diameter is 1nm. The volume of MXene solution in the present embodiment is 8mL, and the solvent of MXene solution is deionized water, and Ti in MXene solution 3 C 2 T x The mass of solute is 80 mg, that of CNT is 40 mg, and that of DMF is 7 mL.

[0065] (2) Drop 2mL of PEDOT:PSS (PH1000) solution on the substrate, heat it on a heating platform at 50°C to form a PEDOT:PSS transparent film, then...

Embodiment 3

[0069] (1) Weigh high-purity carboxylated single-walled carbon nanotubes (CNTs), draw MXene solution with a pipette gun, mix, add (nitrogen, nitrogen-dimethylformamide) DMF, and ultrasonicate for 90 minutes in an ice bath to form MXene / CNT dispersion. Among them, CNT and Ti 3 C 2 T x The concentration of solute in DMF is 8mg / ml, Ti 3 C 2 T x The mass ratio of solute to CNT is 1:2, the concentration of MXene solution is 10mg / mL; the purity of high-purity carboxylated single-walled carbon nanotubes is 90%, and the diameter is 1nm. The volume of MXene solution in the present embodiment is 4mL, and the solvent of MXene solution is deionized water, and Ti in MXene solution 3 C 2 T x The mass of solute is 40 mg, that of CNT is 80 mg, and that of DMF is 11 mL.

[0070] (2) Drop 2mL of PEDOT:PSS (PH1000) solution on the substrate, heat it on a heating platform at 50°C to form a PEDOT:PSS transparent film, then drop 2mL of the dispersion on the transparent film, and heat it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com