Wire-planting circuit board, its processing method and processing equipment

A processing method and circuit board technology, applied in printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problems of uneven impedance, not high-frequency high-speed materials, large microstrip lines, etc., and achieve uniform physical properties , Reliable mechanical performance, good electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

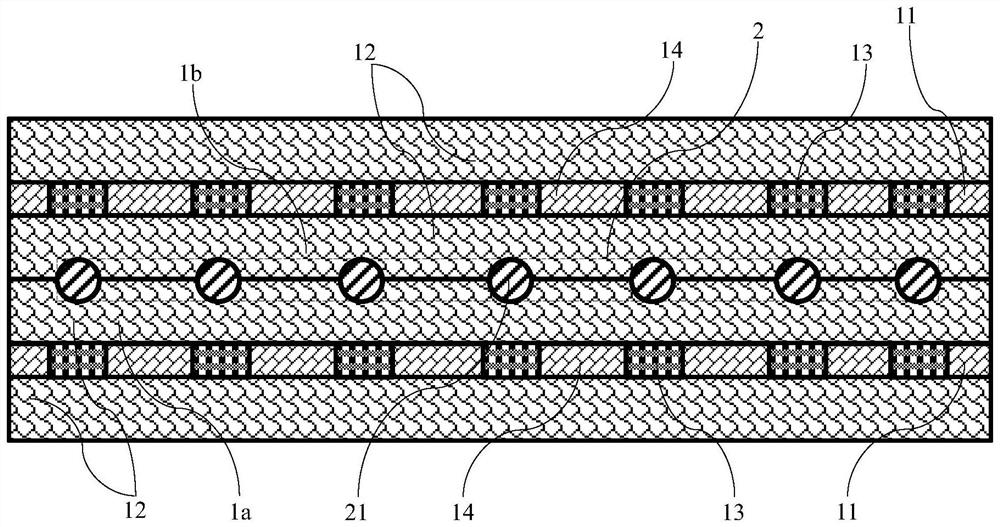

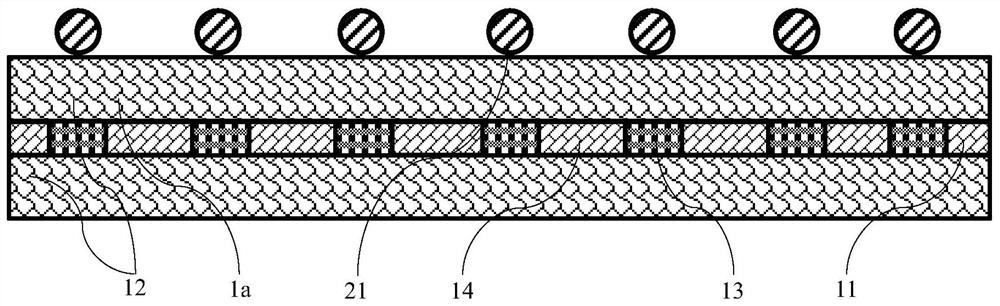

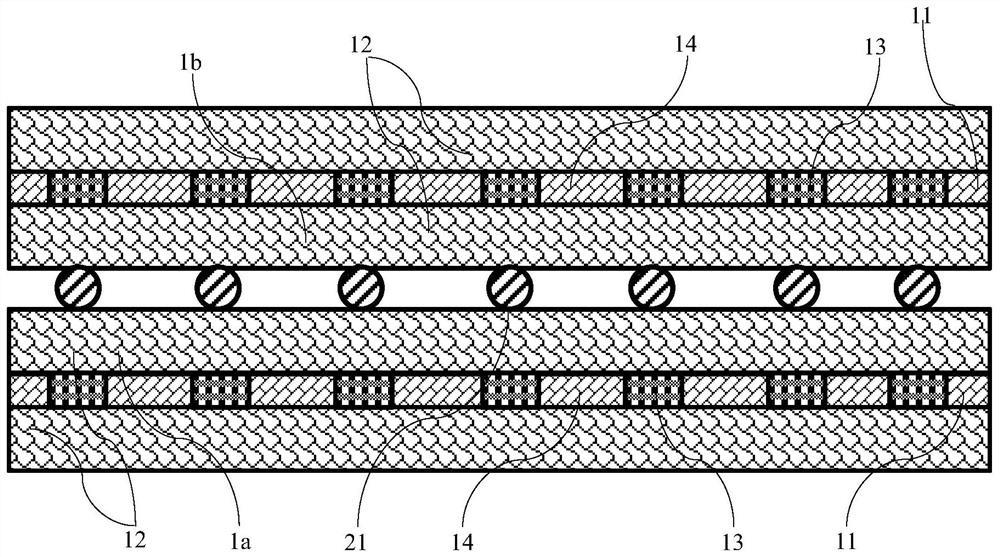

[0050] refer to figure 1 As shown in the figure, a schematic cross-sectional view of an embodiment of the wire-planting circuit board provided by the present invention is shown, and unnecessary structural features are canceled. Of course, it is not used to limit the weaving process of glass fiber cloth, but is only used to illustrate the composition of the planting involved in the present invention. The basic structural relationship between the various components of the circuit board is shown. The wire-planted circuit board provided by the present invention includes: prepreg layers 1a, 1b, the prepreg layers include a reinforcing part 11 and a bonding part 12, and the reinforcing part 11 has lines. figure 1 As shown in , the texture is formed by warp threads 13 and weft threads 14. The wire layer 2 , the wire layer 2 is implanted at the bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com