Gel preparation system

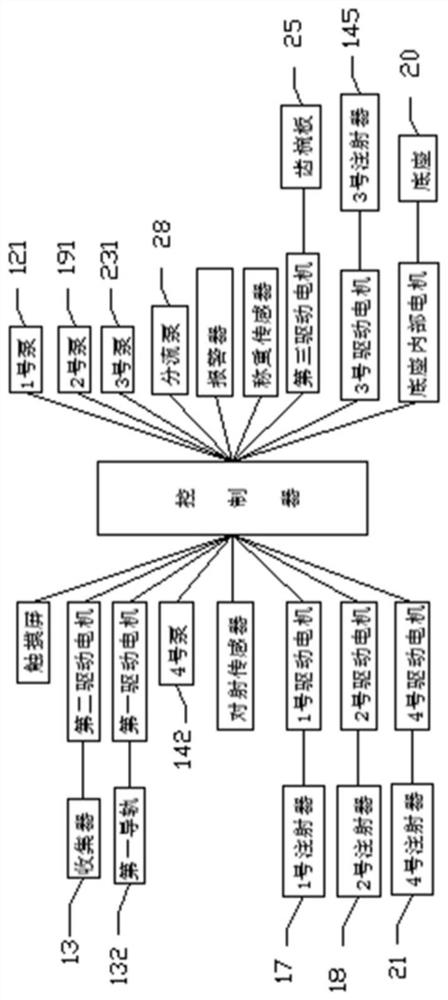

A preparation system and gel technology, applied in gel preparation, colloid chemistry, colloid chemistry, etc., can solve the problems of wrong addition of reagents, strong neurotoxicity, hazards to experimenters, etc., save intermediate transfer links, and have a high degree of automation , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

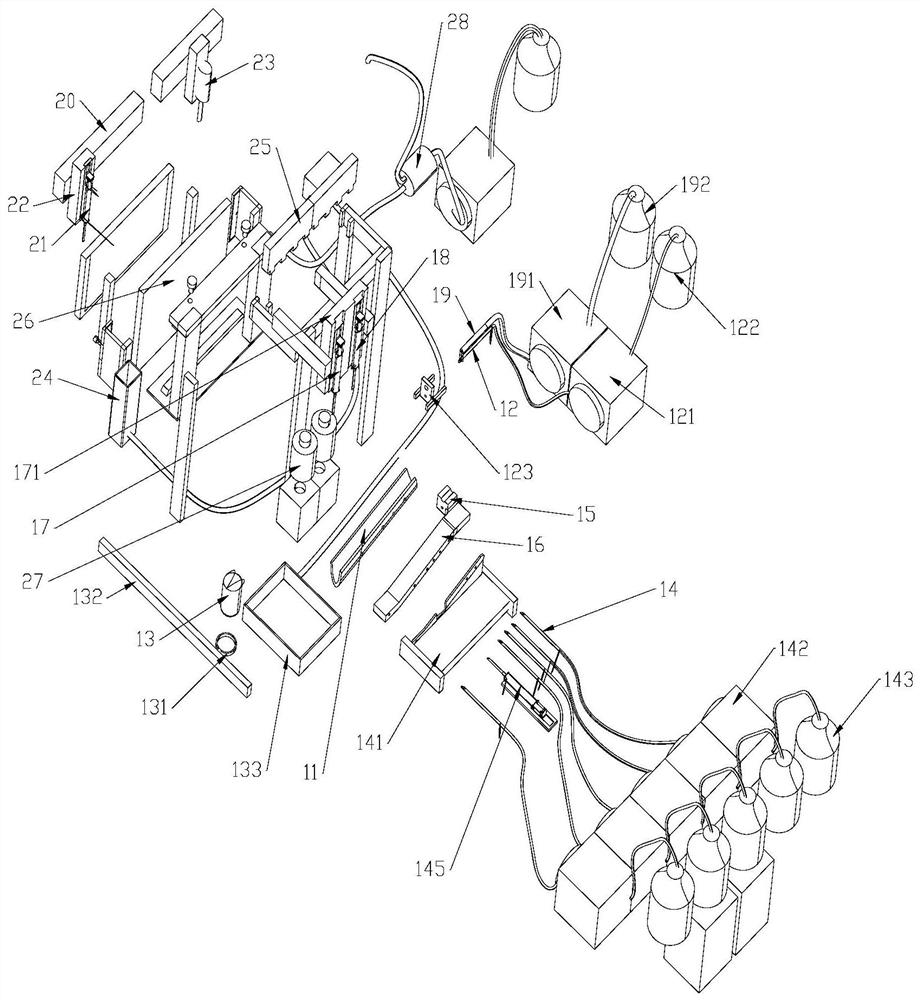

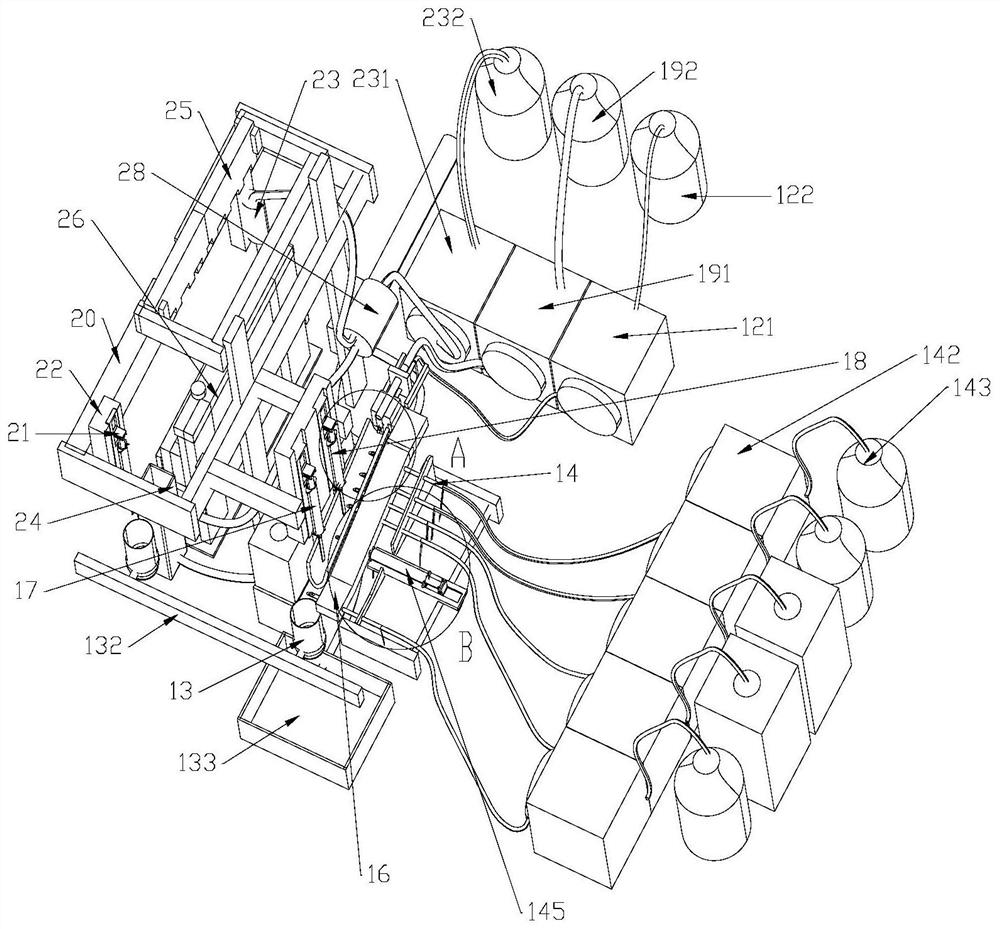

Embodiment 1

[0117] Embodiment 1: It is divided into upper layer glue and lower layer glue. The process of cleaning is required in the middle of the preparation of upper layer glue and lower layer glue. .8), ammonium persulfate, SDS, TEMED, six kinds of liquids, the consumption 1ml of mixed solution is example, the add-on of double distilled water is 0.68ml, adopts the first injection needle 12 to inject liquid, the add-on of acrylamide is 0.17ml, the addition of tris-Hcl (pH6.8) is 0.13ml, the two second injection needles 14 are used for injection, the addition of ammonium persulfate is 10μl, and the No. 1 syringe 17 is used, and the lower end corresponds to The solution supply bottle is equipped with a refrigerator outside, the amount of TEMED is 1 μl, and No. 2 syringe 18 is used, and a refrigerator is installed outside the solution supply bottle corresponding to the lower end; the addition of SDS is 10ul, and No. 3 syringe 145 is used for injection.

[0118] The lower layer of gel is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com