Silicon-containing graphene oxide magnetic polycarboxylate superplasticizer containing allyl alcohol polyoxyethylene ether

A technology of polyoxyethylene ether and water reducing agent, which is applied in the field of building materials, can solve the problems of incompatibility between polycarboxylate water reducing agent and concrete, easy bleeding of fresh concrete, rapid collapse and other problems, and achieve product Remarkable effect, improved slurry fluidity and retention, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

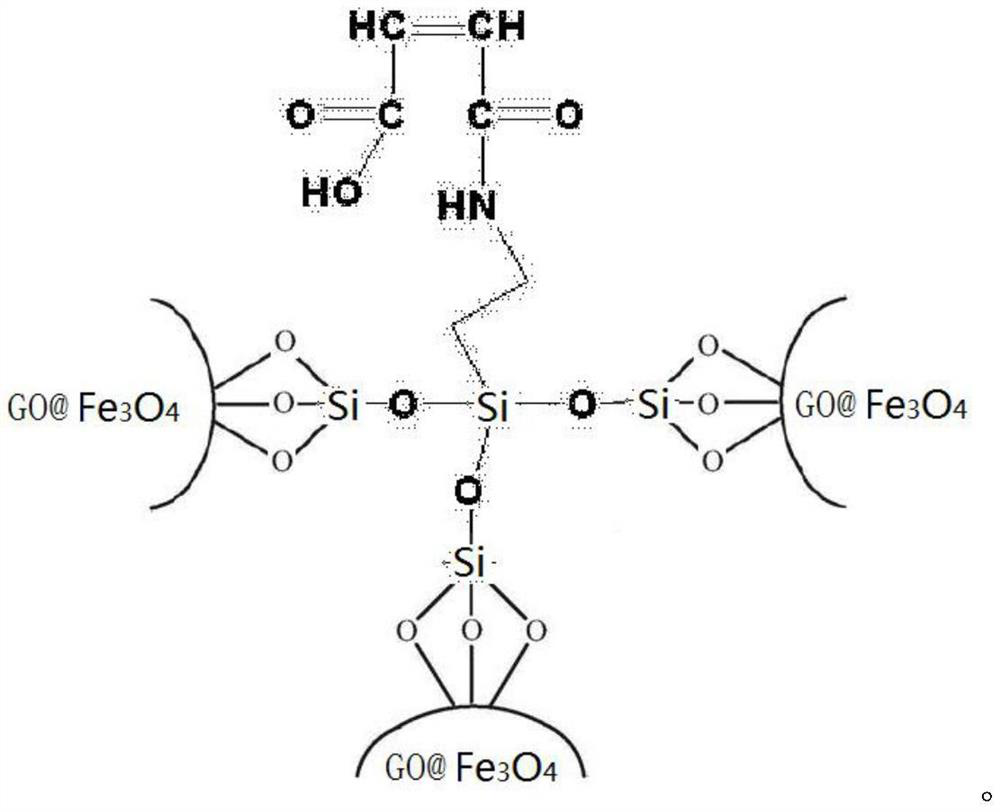

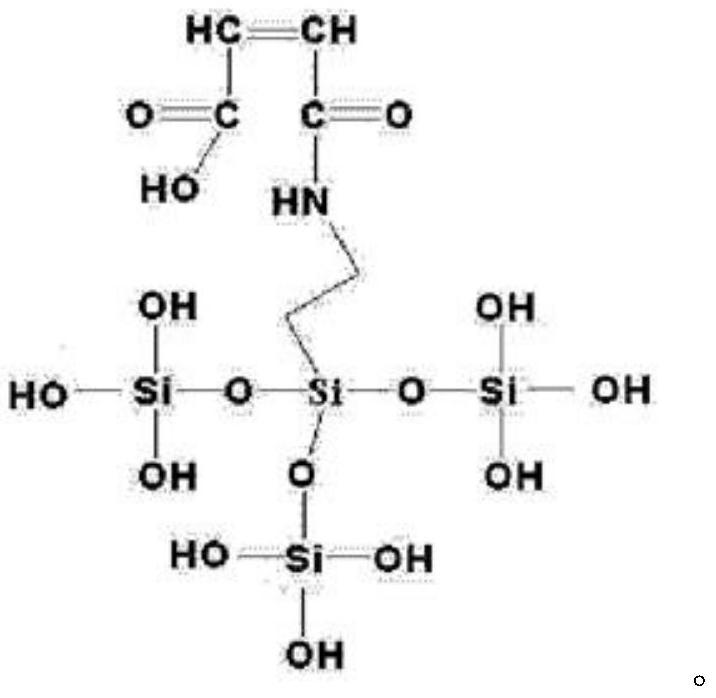

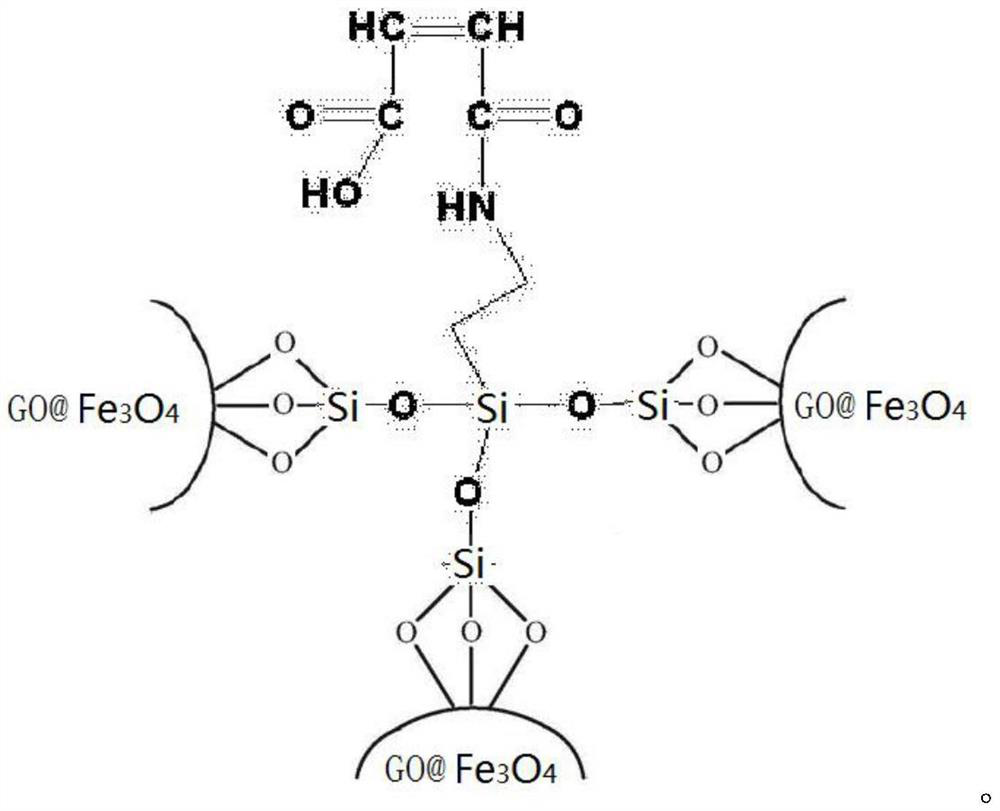

Method used

Image

Examples

Embodiment 1

[0040] Add polyoxyethylene ether A, polyoxyethylene ether B and deionized water into the reaction kettle, heat and dissolve at 20-80°C to obtain A solution; add ammonium persulfate deionized solution dropwise to A solution at the same time Aqueous solution and deionized water mixed solution of acrylic acid, silane C, and mercaptopropionic acid were added dropwise at 60°C for 3.0h, and after the dripping was completed, kept at 60°C for 1.0h, and cooled to room temperature after the reaction to obtain solution B; Then add liquid caustic soda with a mass fraction of 30% to the solution B to adjust the pH value to 6-8 to obtain a polycarboxylate superplasticizer.

[0041] The structure of polyoxyethylene ether A is:

[0042] Where n=35, polyoxyethylene ether B is allyl alcohol polyoxyethylene ether, and the number of repeating units is 200;

[0043] The consumption of each component is:

[0044] Polyoxyethylene ether A15 parts

[0045] Polyoxyethylene ether B15 parts

[0046...

Embodiment 2

[0052] Others are the same as in Example 1, except that n=20 of polyoxyethylene ether A.

Embodiment 3

[0054] Others are the same as in Example 1, except that n=50 of polyoxyethylene ether A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com