Antibacterial wood-plastic composite material based on in-situ growth of nano silver and preparation method of antibacterial wood-plastic composite material

A wood-plastic composite material and in-situ growth technology, which is applied in the field of polymer materials, can solve the problems of complex preparation process of composite materials, easy to be corroded by microorganisms, complicated use of reagents, etc., to achieve secondary in-situ growth and long-term antibacterial time , Improve the effect of interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

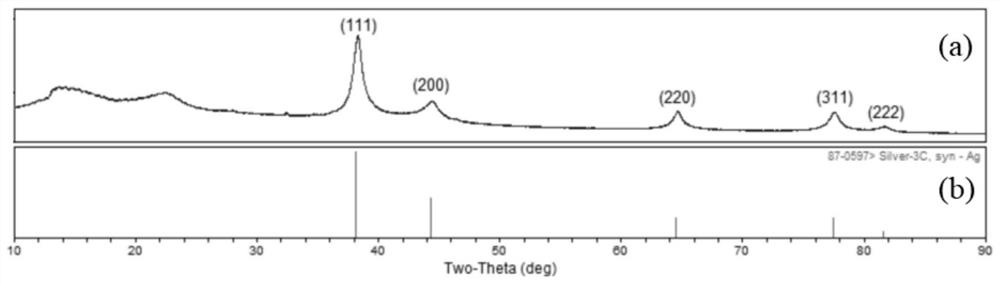

[0039] (1) Disperse 200 mesh bamboo wood powder, silver nitrate and silver acetate in water according to the mass ratio of 25:1:1, then add 5% (the mass of plant fiber powder, silver salt, silane coupling agent in the total ratio) of γ-glycidyl etheroxypropyl trimethoxysilane, after uniform stirring, absorb in the dark for 60 minutes, and then place it in an oven at 90°C for 24 hours to obtain silver-loaded plant fiber powder, and its XRD pattern is as follows figure 1 shown;

[0040] (2) In parts by weight, 88 parts of low-density polyethylene resin (model is 2426K), 1.8 parts of maleic anhydride grafted low-density polyethylene (laboratory self-made, described maleic anhydride grafted low-density polyethylene The method in the preparation method reference document J.Appl.Polym.Sci.2003,90,1249, here only the acrylonitrile-butadiene-styrene copolymer in the document is replaced by low-density polyethylene), 0.1 part Antiaging agent tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphen...

Embodiment 2

[0043] (1) Disperse 40 mesh pine wood powder and silver acetate in water according to the mass ratio of 20:1, and then add 1% (mass ratio in the sum of plant fiber powder, silver salt, and silane coupling agent) of γ-formazan Acryloyloxypropyltrimethoxysilane, after uniform stirring, absorb in the dark for 10 minutes, and then dry in an oven at 60°C for 36 hours to obtain silver-loaded plant fiber powder;

[0044] (2) In parts by weight, first 70 parts of ethylene-octene copolymers (the model is 8100), 7 parts of maleic anhydride grafted ethylene-octene copolymers (made by the laboratory, the maleic anhydride grafted The preparation method of ethylene-octene copolymer refers to the method in the document J.Appl.Polym.Sci.2003,90,1249, here only the acrylonitrile-butadiene-styrene copolymer in the document is replaced by ethylene- octene copolymer), 0.5 parts of anti-aging agent β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and 0.5 parts of 2,6-di-tert-butyl-p-cr...

Embodiment 3

[0047] (1) Disperse 600 mesh poplar wood powder and silver nitrate in water according to a mass ratio of 10:1, and then add 12% (mass ratio in the sum of plant fiber powder, silver salt, and silane coupling agent) of vinyl Triethoxysilane, after uniform stirring, absorb in the dark for 200 minutes, and then place it in an oven at 120°C for 18 hours to obtain silver-loaded plant fiber powder;

[0048] (2) In parts by weight, 35 parts of polypropylene resin (the model is 1450T), 5 parts of ethylene-octene copolymer (the model is 8100), 13 parts of maleic anhydride grafted polypropylene (made by the laboratory, the The method in the reference document J.Appl.Polym.Sci.2003,90,1249 of the preparation method of maleic anhydride grafted polypropylene, here only the acrylonitrile-butadiene-styrene copolymer in the document is replaced by Polypropylene), 1 part of anti-aging agent N-N'-bis(β-naphthyl)-p-phenylenediamine and 1 part of triphenyl phosphite are uniformly melted and compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com