Preparation method for improving mechanical property of polyurethane flame-retardant material

A flame retardant material, polyurethane technology, applied in the field of preparation of improving the mechanical properties of polyurethane flame retardant materials, can solve the problems of poor stability, large particle size of water-based polyurethane emulsion, etc., to improve compatibility, meet the needs of industrial use, and be environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

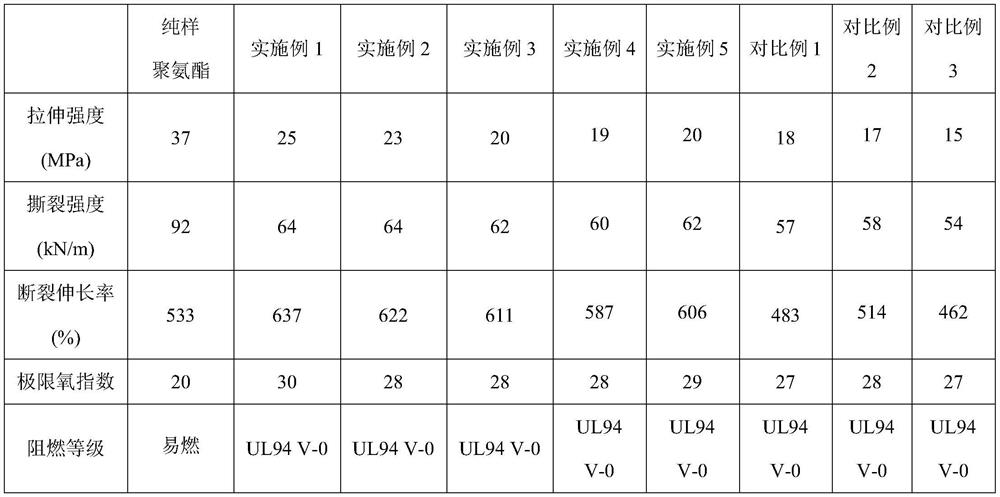

Examples

Embodiment 1

[0041] A preparation method for improving the mechanical properties of polyurethane flame retardant materials, comprising the following steps:

[0042] 1) Preparation of melamine / polyurethane composite suspension

[0043] Dilute 0.20 kg of polyurethane emulsion in 100 kg of water, and stir for 3 hours at 40° C. with a stirring speed of 300 rpm to obtain a diluted polyurethane solution. Add 4kg of melamine and 100kg of water into the ultrasonic irradiation reactor, and ultrasonically disperse for 2 hours under the conditions of ultrasonic power of 300W, frequency of 300Hz, and 40°C to obtain a melamine dispersion; Under the condition of 12mL / min, slowly add the prepared melamine dispersion into the polyurethane solution to obtain a stable melamine / polyurethane composite suspension.

[0044] 2) Preparation of melamine / polyurethane composite masterbatch

[0045] The melamine / polyurethane composite suspension was washed by suction filtration, and dried to constant weight at a va...

Embodiment 2

[0049] A preparation method for improving the mechanical properties of polyurethane flame retardant materials, comprising the following steps:

[0050] 1) Preparation of melamine / polyurethane composite suspension

[0051] Add 0.50 kg of polyurethane emulsion and 300 kg of absolute ethanol into a three-necked flask, heat and stir for 3 hours at a temperature of 70° C. and a stirring speed of 400 rpm to obtain a diluted polyurethane solution.

[0052] Add 20kg of melamine and 400kg of water into an ultrasonic irradiation reactor, and ultrasonically disperse for 1.5 hours under the conditions of ultrasonic power of 400W, frequency of 400Hz, and temperature of 70°C to obtain a melamine solution.

[0053] 2) Preparation of melamine / polyurethane composite masterbatch

[0054] Add the obtained melamine solution to the diluted polyurethane solution to obtain a melamine / polyurethane composite suspension, and then dry it to constant weight at a vacuum degree of 0.1MPa and a temperature...

Embodiment 3

[0058] A preparation method for improving the mechanical properties of polyurethane flame retardant materials, comprising the following steps:

[0059] 1) Preparation of melamine / polyurethane composite suspension

[0060] Add 1kg of polyurethane emulsion and 800kg of DMF into the ultrasonic cleaning machine, start the ultrasonic cell pulverizer, the ultrasonic power is 10000W, the frequency is 20000Hz, the temperature is 30°C, and the ultrasonic dispersion time is 30 minutes to obtain a polyurethane dilute solution.

[0061] Add 30 kg of melamine and 800 kg of water into a three-necked flask, heat and stir for 4 hours at a temperature of 120° C. and a stirring speed of 300 rpm to obtain a melamine solution.

[0062] 2) Preparation of melamine / polyurethane composite masterbatch

[0063] The obtained melamine solution was added to the dilute polyurethane solution to obtain a melamine / polyurethane composite suspension, and the product was dried to constant weight at a vacuum deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com