Coal bed long-hole drilling deposited coal cinder water-discharging system and cinder discharging method

A technology for long drilling and coal seam, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling, etc., can solve the problems of difficult drilling and difficult discharge of coal slag, and can increase the power of slag discharge at the bottom of the hole and reduce the The effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

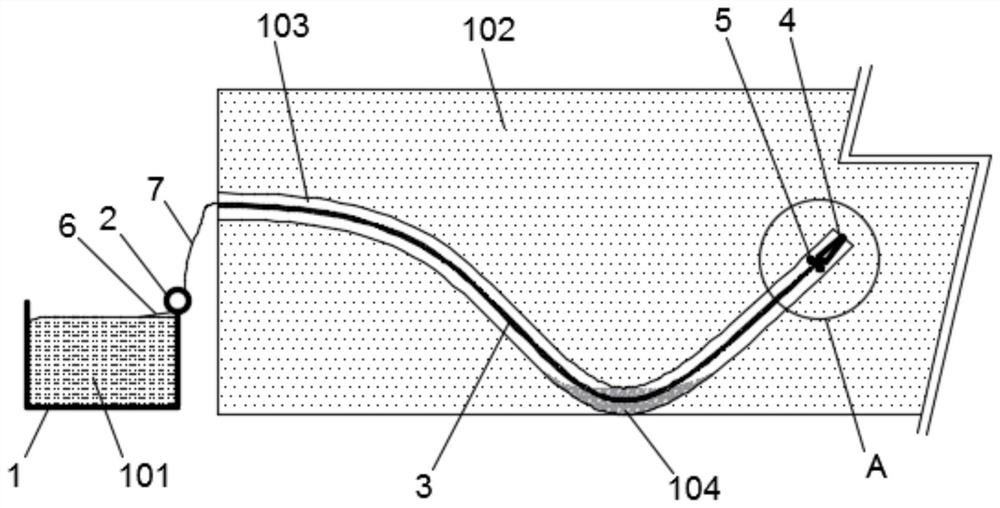

[0035] like figure 1 As shown, this embodiment discloses a long coal seam drilling water drainage deposition cinder system, including a box body 1, a water pump 2, a drill pipe 3, a drill bit 4, a swirl device 5, a first infusion pipe 6 and a second Infusion tube 7; as figure 1 As shown, the number 101 in the figure is a high-density aqueous solution, the number 102 is a coal seam, the number 103 is a drill hole, and the number 104 is cinder.

[0036] like figure 1 As shown, the box body 1 of this embodiment is an existing water tank structure, and the top sealing structure of the box body 1 is not provided. The top of the box body 1 is equipped with a matching box cover, and a feeding port and a water outlet are also provided on the box cover. ; The high-density aqueous solution 101 is added to the inside of the box body 1 of this embodiment through the feeding port.

[0037] like figure 1 As shown, the water inlet of the water pump 2 communicates with the water outlet of...

Embodiment 2

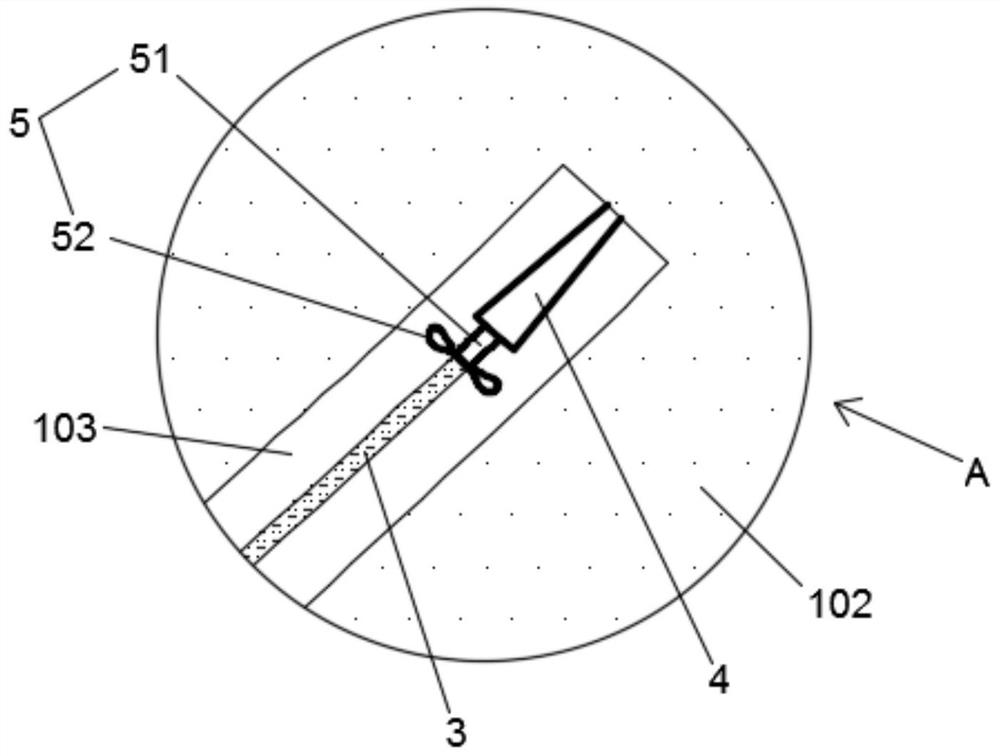

[0051] The difference between this embodiment and the above-mentioned embodiment is that: figure 2 As shown, the stirring member 52 of this embodiment adopts the existing impeller structure, and is a spiral impeller structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com