Bearing and vibration isolation integrated plate shell superstructure and design method thereof

A design method and superstructure technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problems of high use cost, low bearing capacity, large volume of vibration isolators, etc., to reduce machining errors and The effect of changing operating frequency, improving isolation capability, and improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

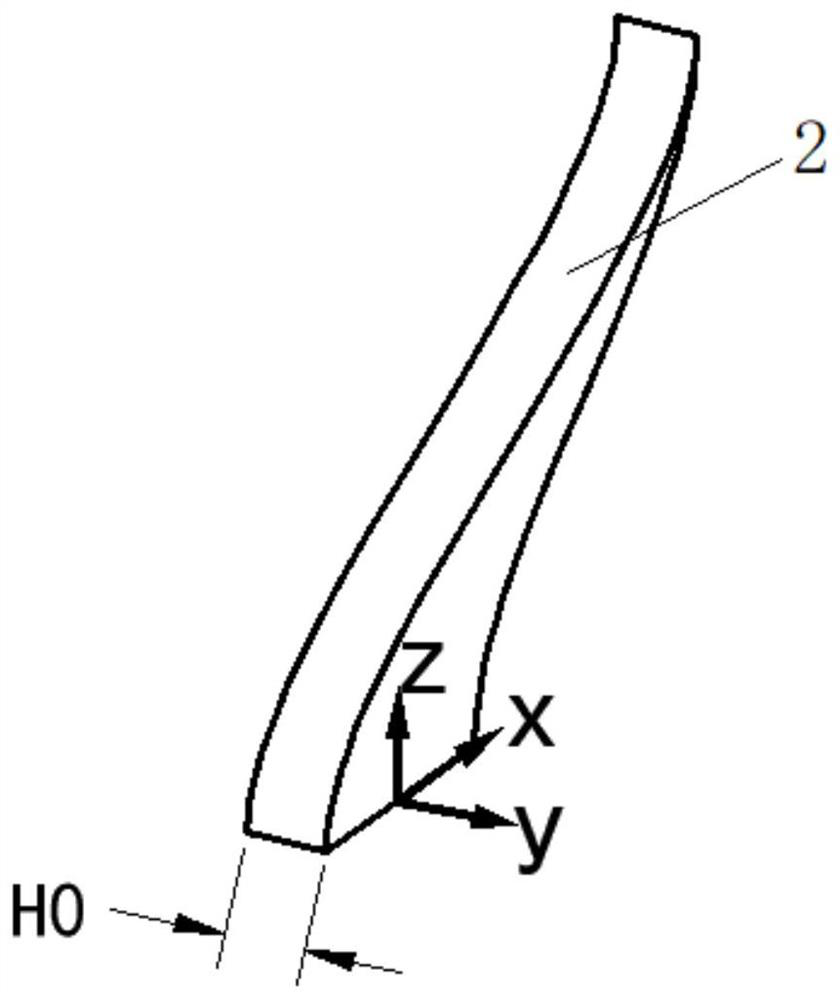

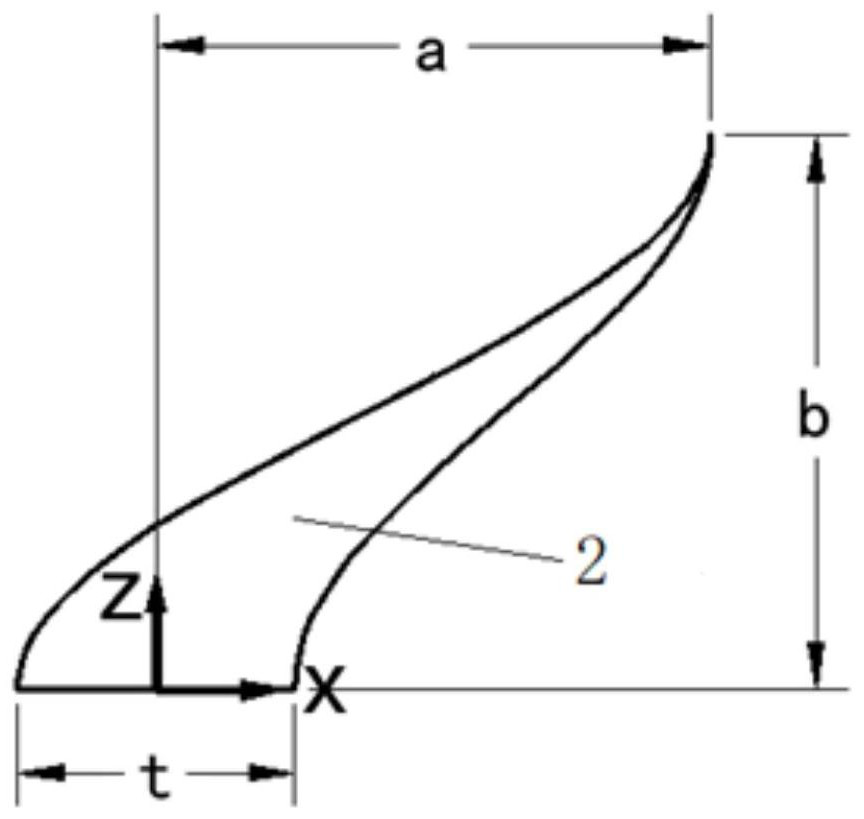

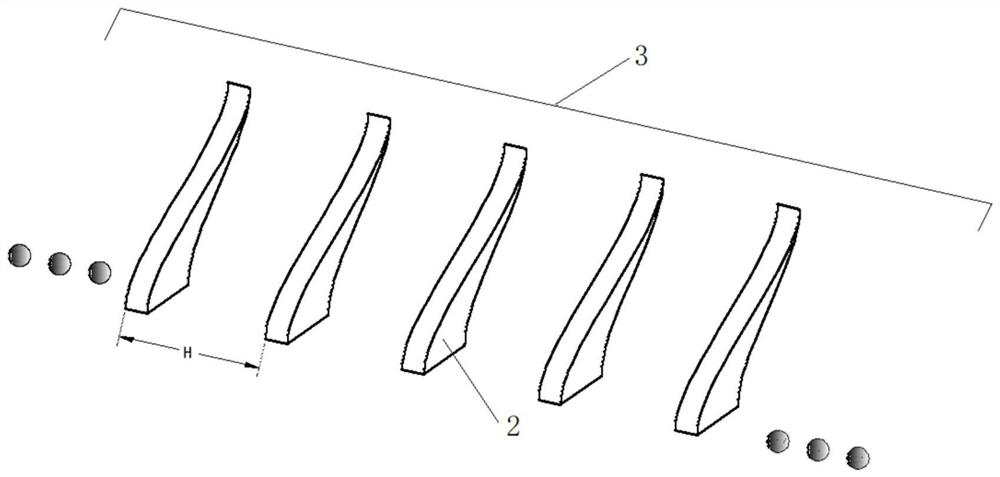

[0047]The load-bearing and vibration-isolation integrated plate-shell superstructure of the present invention includes a plate shell 1 and a number of microstructure components 2; Composed of arcsine function curves, the intersection of two similar arcsine function curves forms the tip of the beak; the bottom surface of the microstructure component 2 is connected to the plate shell 1, preferably, the material of the plate shell 1 and the microstructure component 2 is the same, and can be used 3D printing integrated molding. A number of microstructure components 2 are periodically arranged to form an array 3 , which separates the vibration source 4 and the protected object 5 .

[0048] Shell 1 such as Figure 4 As shown, its length, width and thickness are L, W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com