Silicon wafer thermal oxidation wet oxygen process

A technology of thermal oxidation and wet oxygen, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as system pollution, poor process stability, and inability to accurately control the amount of wet oxygen steam, so as to solve potential safety hazards , Improve safety and reliability, and reduce the chance of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

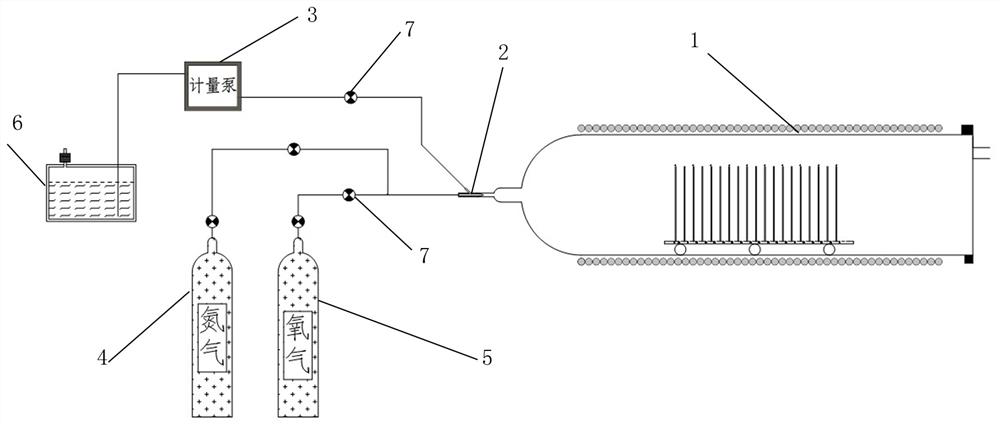

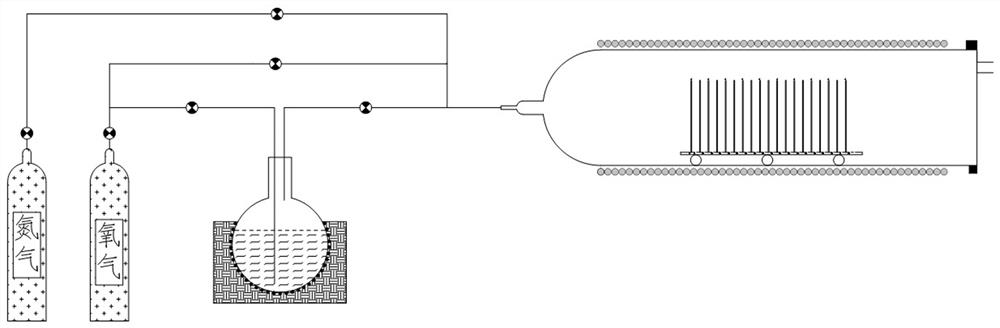

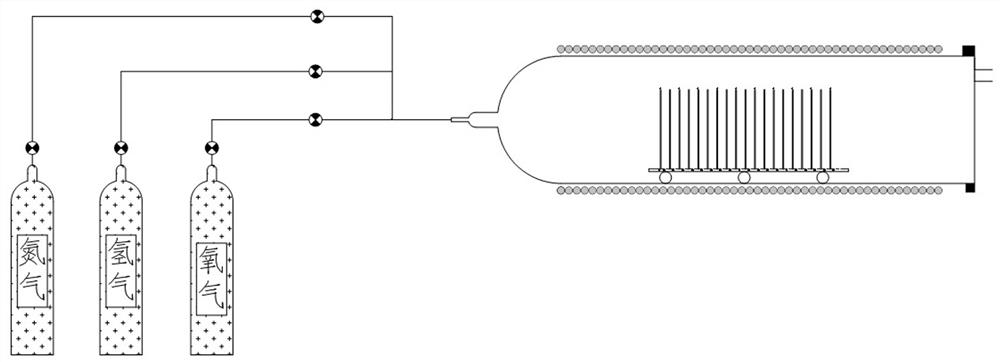

[0027] Such as figure 1 As shown, a silicon chip thermal oxidation wet oxygen process, the system used in the wet oxygen process includes an oxidation furnace tube 1, a gas nozzle 2, a metering pump 3, a nitrogen tank 4, an oxygen tank 5, the oxidation furnace tube The rear part of 1 is provided with connected gas nozzle 2 and metering pump 3;

[0028] The wet oxygen process includes the following steps:

[0029] S1: PFA high-purity water container 6 is set in the system;

[0030] S2: The PFA high-purity water container 6 is provided with an air inlet, and a high-efficiency filter is arranged in the air inlet, and other places...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com