Paper for total heat exchanging element and total heat exchanging element

A technology of full heat exchange and components, applied in heat exchange equipment, heat exchange materials, paper, etc., can solve the problems of reduced energy saving effect, achieve the effects of increased yield, improved fibrillation rate, and improved gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

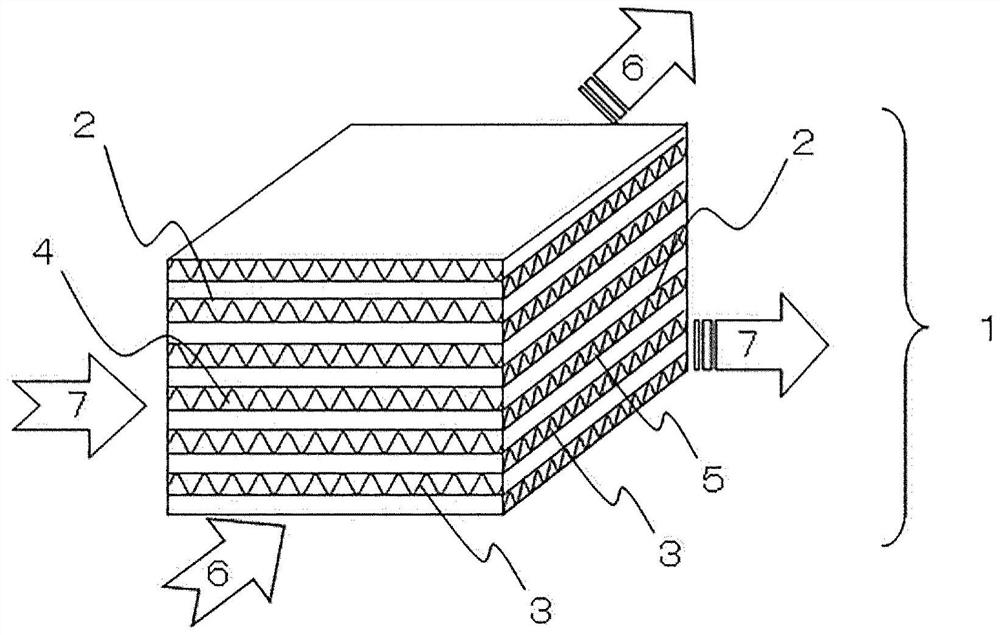

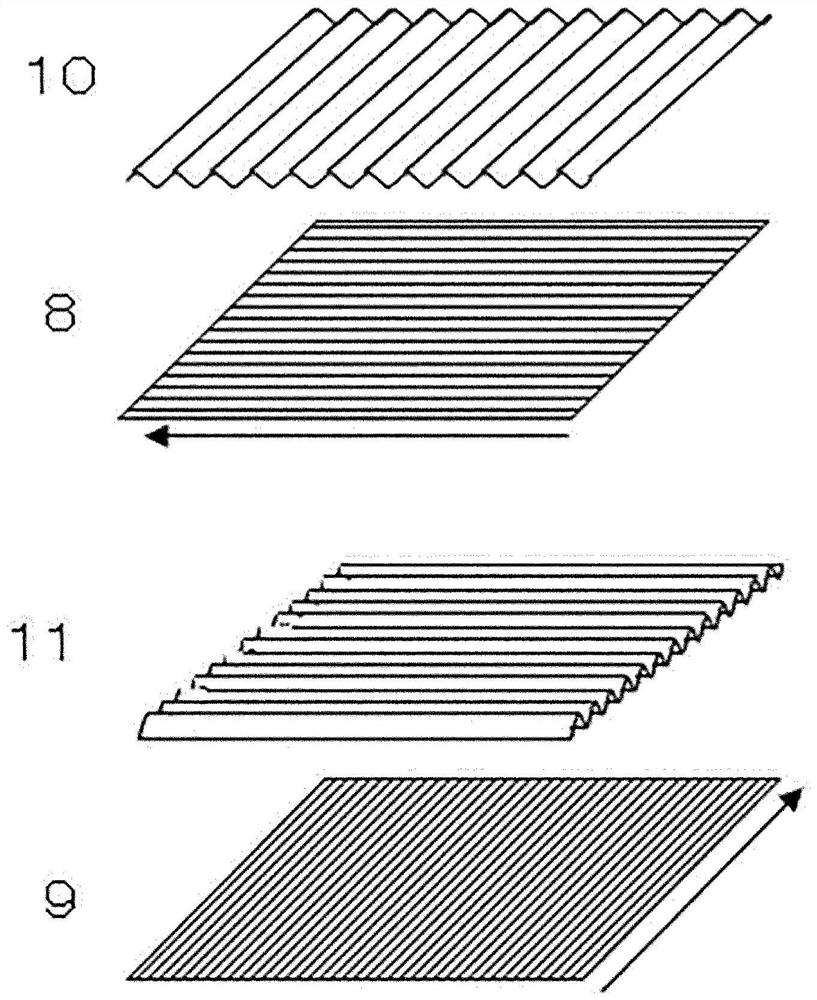

Method used

Image

Examples

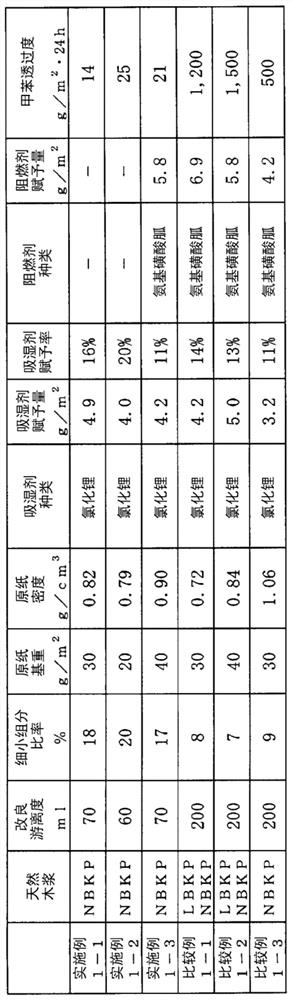

Embodiment 1-1

[0073] After dissociating conifer bleached kraft pulp (NBKP) at a concentration of 4.5% (weight ratio), use a double-action disc refiner to beat, and use a fourdrinier paper machine to produce a basis weight of 30g / m 2 base paper, so that the density of the base paper is 0.82g / cm 3 by means of mechanical calendering. Add lithium chloride 4.9g / m as a hygroscopic agent to the base paper using an impregnation processing machine 2 , to obtain paper for total heat exchange elements. The fines ratio of the beaten wood pulp was 18%.

Embodiment 1-2

[0075] After dissociating conifer bleached kraft pulp (NBKP) with a concentration of 4.5%, it is beaten with a double-moving disc refiner, and a basis weight of 20g / m is produced using a Fourdrinier paper machine. 2 base paper, so that the density of the base paper is 0.79g / cm 3 by means of mechanical calendering. Add lithium chloride 4.0g / m as a hygroscopic agent to the base paper using an impregnation processing machine 2 , to obtain paper for total heat exchange elements. The fines ratio of the beaten wood pulp was 20%.

Embodiment 1-3

[0077] After dissociating conifer bleached kraft pulp (NBKP) with a concentration of 4.5%, it is beaten with a double-moving disc refiner, and a basis weight of 40g / m is produced using a Fourdrinier paper machine. 2 base paper so that the density of the base paper is 0.90g / cm 3 by means of mechanical calendering. Adding 5.8 g / m of guanidine sulfamate as a flame retardant to base paper using an impregnation processing machine 2 , and then, give lithium chloride as a hygroscopic agent 4.2g / m 2 , to obtain paper for total heat exchange elements. The fines ratio of the beaten wood pulp was 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com