Solid-liquid separation method for Fischer-Tropsch synthetic wax

A Fischer-Tropsch synthetic wax and solid-liquid separation technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of large loss of spare parts, good filtering effect, and high maintenance frequency, and achieve low loss of spare parts and separation effect. Good, the effect of low maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

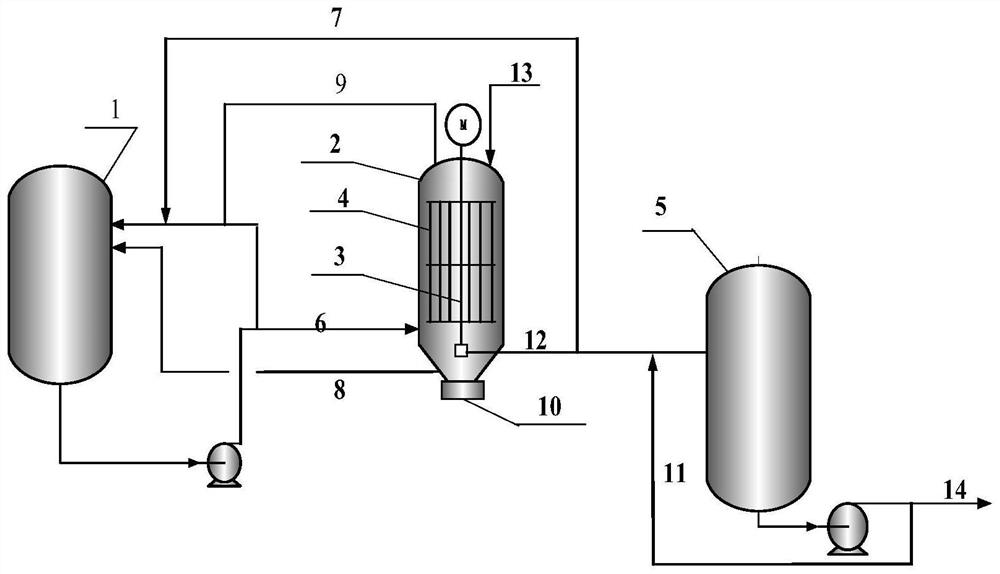

Image

Examples

specific Embodiment approach

[0044] In a specific embodiment, nitrogen gas is introduced into the filter to return the raw material wax to the raw material tank. In this specific implementation manner, it is more conducive to reducing operating costs.

[0045] In a specific embodiment, after the filter is evacuated, the nitrogen in the filter is drawn out, so that the pressure in the filter is reduced to the equal pressure of the atmosphere, and then the step (2-2) is carried out .

[0046] According to the present invention, preferably, the backflushing obtains slag wax, and the wax content in the slag wax is not less than 90% by weight, preferably 90-99.9% by weight.

[0047] In a specific implementation manner, the filter includes a slag discharge port, and the slag wax obtained by the slag discharge is discharged from the slag discharge port. The process of the present invention also includes processing the obtained slag wax after collection, the treatment includes but not limited to extraction, sep...

Embodiment approach

[0054] In a preferred embodiment, the flushing obtains a flushing liquid, and the flushing liquid enters the raw material tank. In this preferred implementation manner, it is beneficial to reduce operating costs.

[0055] The manner in which the flushing liquid of the present invention enters the raw material tank is not particularly limited. Specifically, for example, when the flushing liquid is obtained after flushing with qualified wax, the flushing liquid is disposed at the bottom of the filter and the raw material The return line between tanks discharges into the raw material tanks.

[0056] According to the present invention, preferably, the flushing conditions include: the temperature is 120-220°C, preferably 150-200°C; the time is 5-60min, preferably 10-20min; the pressure is 0.1-1.5MPa, preferably 0.1 -0.5MPa.

[0057] According to the present invention, preferably, the method further includes: before step (2-3), introducing the qualified wax into the filter for soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com