Method for preparing iron-based low-temperature denitration catalyst from ilmenite

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unrealized high-value utilization of ilmenite catalysts, improve anti-poisoning performance and reduce production The effect of low cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

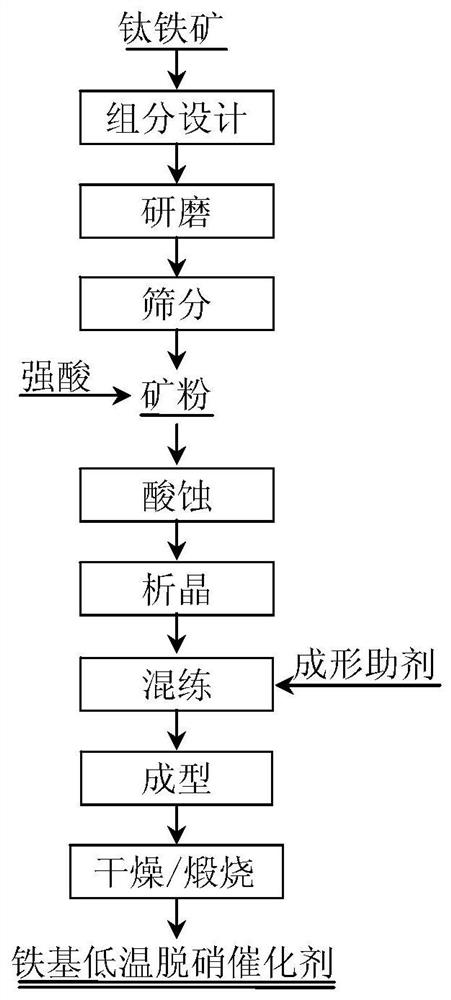

Image

Examples

Embodiment example 1

[0026] A method for preparing an iron-based low-temperature denitrification catalyst using ilmenite, adjusting the composition to FeO x 5%, TiO 2 80%, other SiO 2 、Al 2 o 3 The ilmenite is crushed and finely ground, passed through a 200-mesh sieve, and the fine ore powder under the sieve is taken; adding a sulfuric acid solution with a Fe element content of 110%, and aging for 24 hours after stirring; adjust the pH value to 3, The temperature is 120°C, and the temperature is kept for 6 hours; the molding aid is added for mixing for 3 hours, aged for 36 hours, and finally the honeycomb catalyst wet billet is extruded, dried at 60°C, and finally calcined at 300°C for 48 hours, and the heating rate is 1°C / min. Iron-based low-temperature denitrification catalyst.

Embodiment example 2

[0028] A method for preparing an iron-based low-temperature denitration catalyst using ilmenite, adjusting the composition to FeO x 10%, TiO 2 85%, other SiO 2 、Al 2 o 3 5%; crush and finely grind the ilmenite, pass through a 230-mesh sieve, and take the fine ore powder under the sieve; add nitric acid solution with 100% Fe element content, stir well and age for 20 hours; adjust the pH value to 4, The temperature was 100°C, and the temperature was kept for 9 hours; the molding aid was added to knead for 4 hours, aged for 30 hours, and finally made into a granular catalyst wet billet, which was dried at 80°C, and finally calcined at 350°C for 36 hours, and the heating rate was 3°C / min. Iron-based low-temperature denitrification catalyst.

Embodiment example 3

[0030] A method for preparing an iron-based low-temperature denitration catalyst using ilmenite, adjusting the composition to FeO x 15%, TiO 2 73%, other SiO 2 、Al 2 o 3 12%; crush and finely grind the ilmenite, pass through a 250-mesh sieve, and take the fine ore powder under the sieve; add sulfuric acid and nitric acid mixed solution with 90% Fe element content, stir well and age for 16 hours; adjust the pH value To 5, the temperature is 80°C, keep warm for 12h; add molding aids and knead for 5h, age for 24h, finally prepare the corrugated plate catalyst wet billet, dry at 100°C, and finally roast at 400°C for 24h, the heating rate is 5°C / min , to obtain an iron-based low-temperature denitration catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com