Low-thermal-expansion perfluoride glass ceramic and preparation method thereof

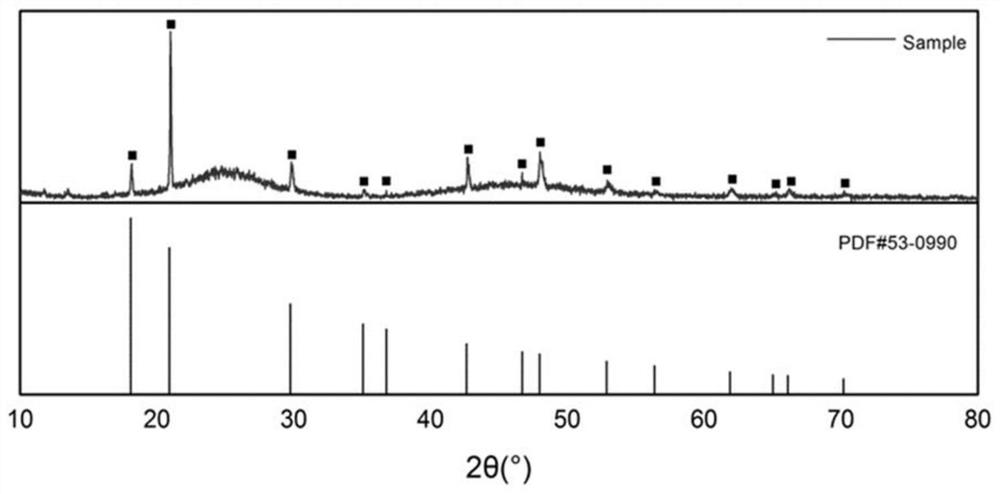

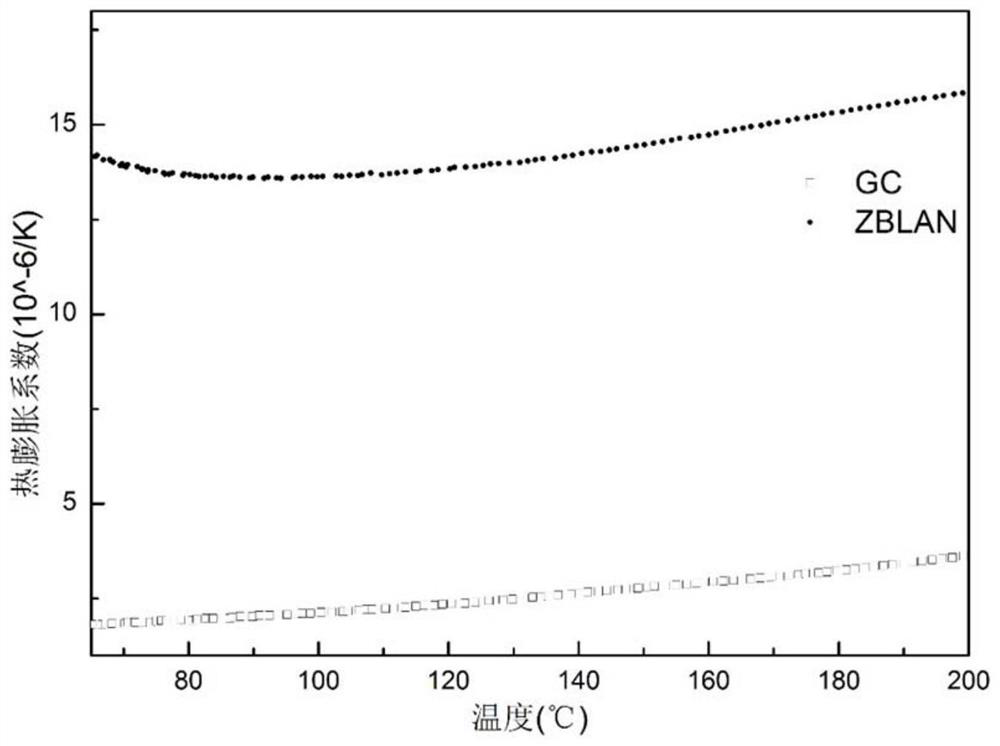

A technology of glass ceramics and low thermal expansion, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as poor thermal stability and complicated preparation of glass ceramics, achieve controllable types and sizes, reduce thermal expansion coefficient, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of raw materials: 53ZrF by molar percentage 4 -20BaF 2 -4LaF 3 -3AlF 3 -10NaF-10CaF 2 Weigh 80g of batch material, and weigh 44.4g of ammonium bifluoride according to the mass ratio of batch material to ammonium bifluoride is 1.8.

[0022] Mixing and drying of the ingredients: put the batching ingredients and ammonium bifluoride in a ball mill tank, add ethanol as a ball milling aid, the weight of the ethanol is equal to the weight of the raw materials, and mill for 30 minutes by a planetary ball mill, and mix the obtained mixed slurry with Put the ball mill pot together into a drying oven at 120°C for 6 hours to obtain the dry batch;

[0023] Melting: Put the dry batch into a platinum crucible and melt at 850°C for 30 minutes to obtain a molten liquid.

[0024] Forming and annealing: put the grooved brass mold into the annealing furnace, and raise the temperature of the annealing furnace to 250°C for standby; open the door of the annealing furnace, dir...

Embodiment 2

[0027] Preparation of raw materials: 53ZrF by molar percentage 4 -20BaF 2 -4LaF 3 -3AlF 3 -8NaF-12CaF 2 Weigh 80g of batch material, and weigh 53.33g of ammonium bifluoride according to the mass ratio of batch material to ammonium bifluoride is 1.5.

[0028] Mixing and drying of the ingredients: the batching ingredients and ammonium bifluoride are placed in a ball mill tank, and the ball milling aid ethanol is added, the weight of the ethanol is equal to the weight of the raw materials, and the resulting mixed slurry is mixed with a planetary ball mill for 45 minutes. Put the ball mill pot together into a drying oven at 120°C for 6 hours to obtain the dry batch;

[0029] Melting: Put the dry batch into a platinum crucible and melt at 850°C for 40 minutes to obtain a molten liquid.

[0030] Forming and annealing: put the grooved brass mold into the annealing furnace, and raise the temperature of the annealing furnace to 260°C for standby; open the door of the annealing fur...

Embodiment 3

[0033] Preparation of raw materials: Weigh 80g of the batch material according to the molar percentage of 53ZrF4-20BaF2-4LaF3-3AlF3-8NaF-12CaF2, and weigh 66.67g of ammonium bifluoride according to the mass ratio of the batch material to ammonium bifluoride is 1.2.

[0034] Mixing and drying of the ingredients: put the batching ingredients and ammonium bifluoride in a ball mill tank, add ethanol as a ball milling aid, the weight of the ethanol is equal to the weight of the raw materials, and mill for 30 minutes by a planetary ball mill, and mix the obtained mixed slurry with Put the ball mill pot together into a drying oven at 120°C for 6 hours to obtain the dry batch;

[0035] Melting: put the dry batch into a platinum crucible and melt at 850°C for 50 minutes to obtain a molten liquid.

[0036] Forming and annealing: put the grooved brass mold into the annealing furnace, and raise the temperature of the annealing furnace to 270°C for standby; open the door of the annealing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com