A preparation method of low-cost environment-friendly microwave absorber

A microwave absorption, low-cost technology, applied in antennas, electrical components, etc., to achieve the effect of enhancing effective electromagnetic absorption performance, low cost, and solving grain boundary air gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

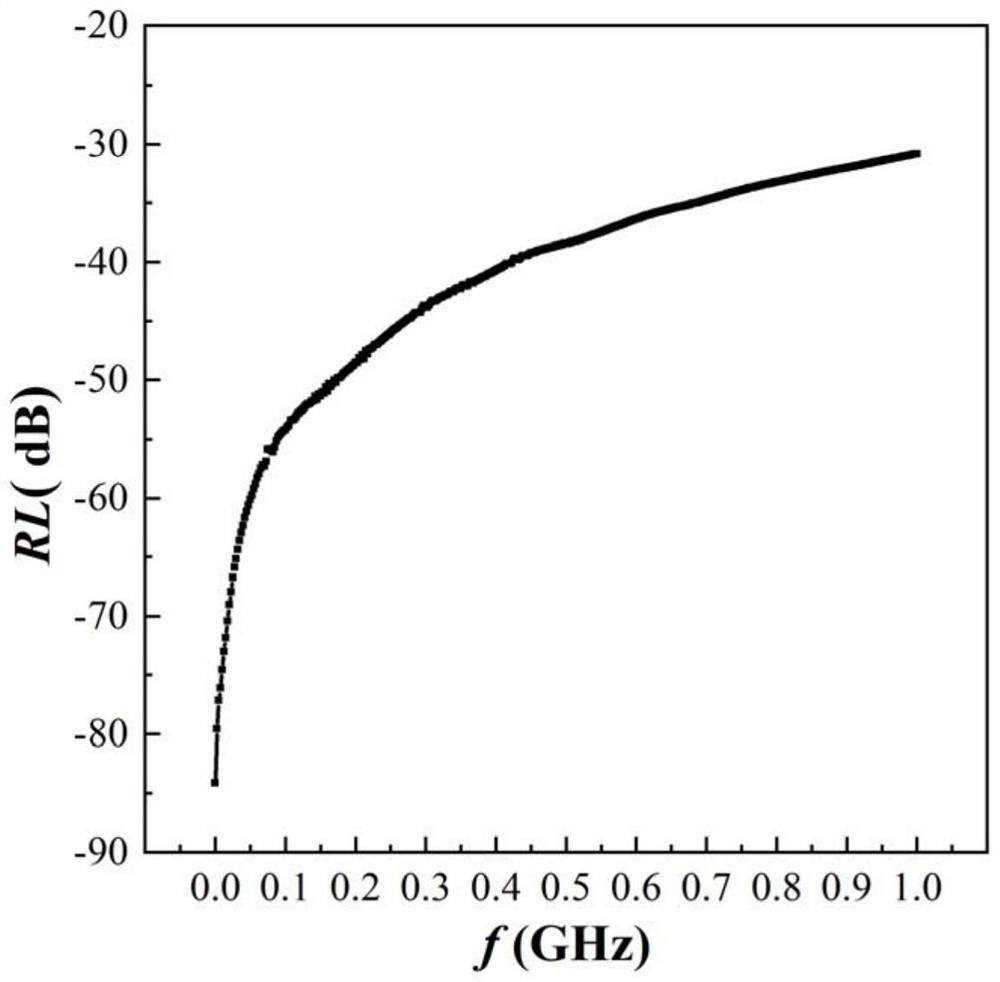

Embodiment 1

[0030] This example uses grinding solid waste, waste green body, and waste products generated during the production process of electromagnetic wave absorption, soft magnetic core materials, and devices as raw materials, and is washed and dispersed, dried and sieved, and ball milled once. Secondary ball milling, pressing molding, high-temperature sintering and other processes to obtain a high-density microwave absorber. The mass ratio of the two solid wastes is 1:9. The specific steps are as follows:

[0031] Step 1: Take the crushed MnZn ferrite magnetic core solid waste powder, and after washing, purifying, drying, sieving and other processes, a powder 1 with a particle size of about 1-75 μm is obtained.

[0032] Step 2: Take the broken manganese-zinc-ferrite wave-absorbing solid waste powder, after washing, purifying, drying and other processes, add it to the ball mill tank according to the ratio of powder: water: ball milling beads mass ratio of 1:1:5 , wet ball milling at ...

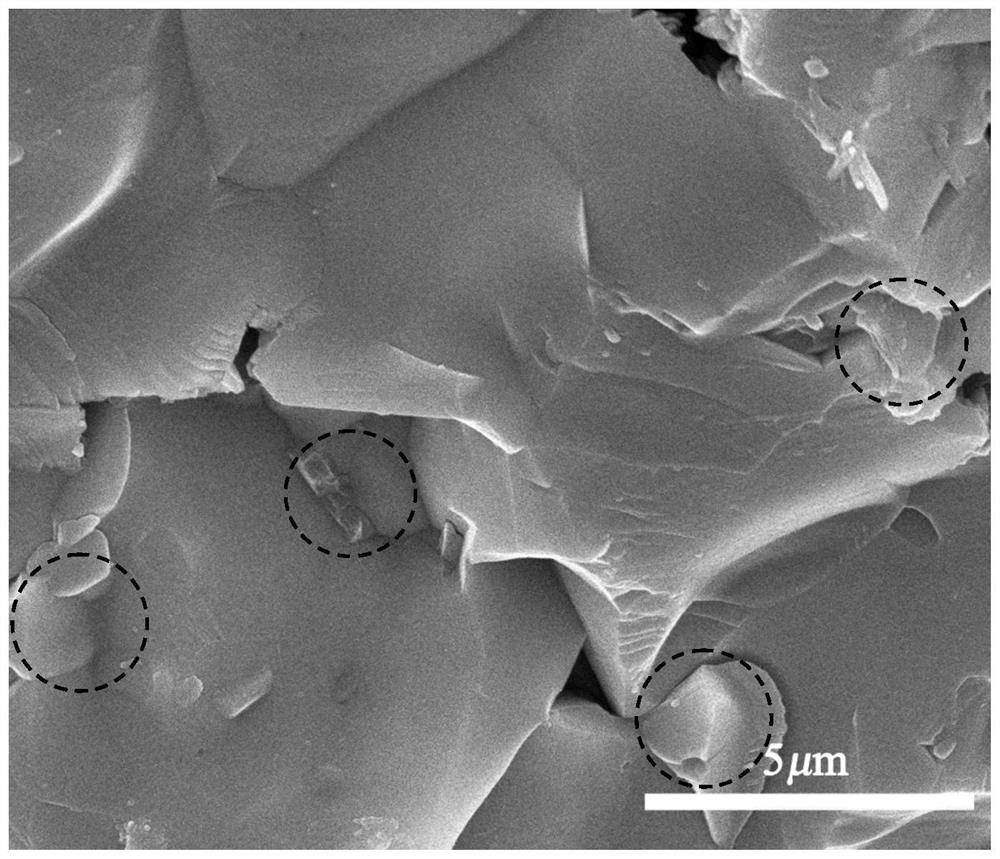

Embodiment 2

[0037] This example uses grinding solid waste, waste green body, and waste products generated during the production process of electromagnetic wave absorption, soft magnetic core materials, and devices as raw materials, and is washed and dispersed, dried and sieved, and ball milled once. Secondary ball milling, pressing molding, high-temperature sintering and other processes to obtain a high-density microwave absorber. The mass ratio of the two solid wastes is 1:2.33. The specific steps are as follows:

[0038] Step 1: Take the crushed MnZn ferrite magnetic core solid waste powder, and after washing, purifying, drying, sieving and other processes, a powder 1 with a particle size of about 1-75 μm is obtained.

[0039] Step 2: Take the crushed manganese-zinc-ferrite wave-absorbing solid waste powder, after washing, purifying, drying and other processes, add it to the ball milling tank according to the mass ratio of powder: water: ball milling beads: 1:1.2:6 In the process, wet b...

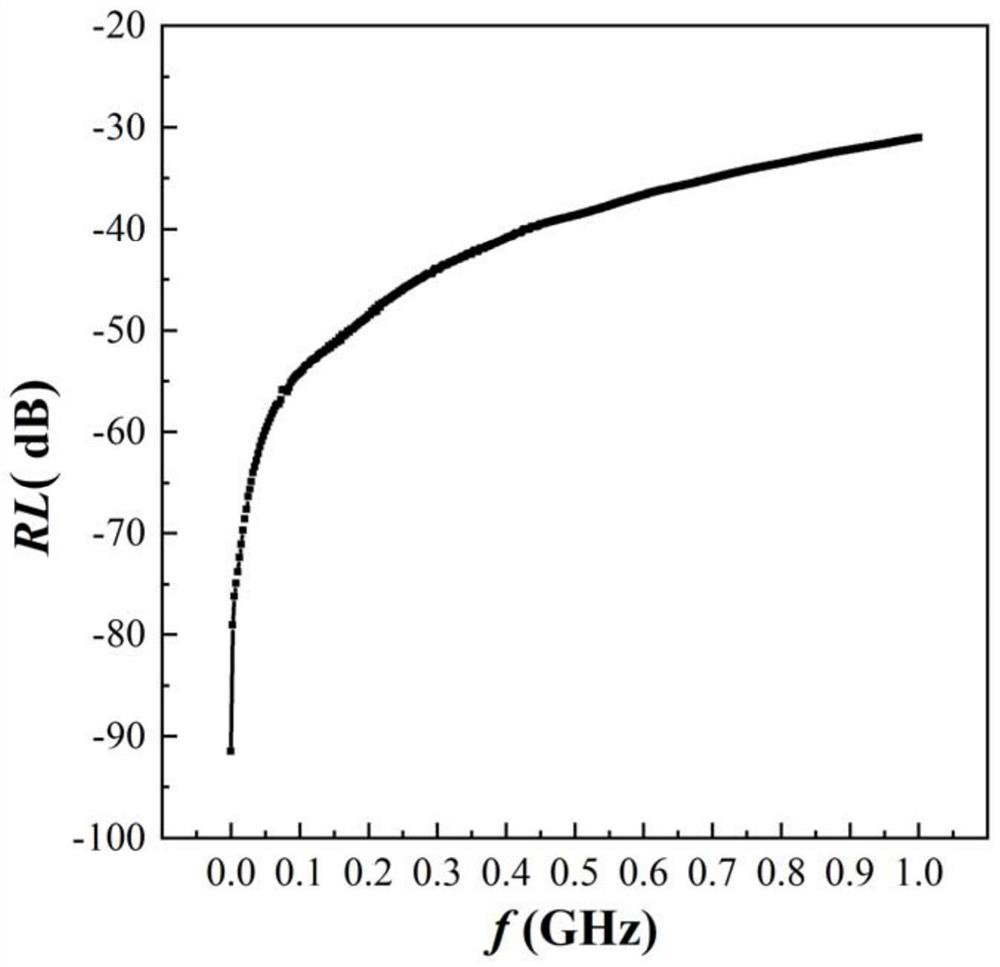

Embodiment 3

[0044] This example uses grinding solid waste, waste green body, and waste products generated during the production process of electromagnetic wave absorption, soft magnetic core materials, and devices as raw materials, and is washed and dispersed, dried and sieved, and ball milled once. Secondary ball milling, pressing molding, high-temperature sintering and other processes to obtain a high-density microwave absorber. The mass ratio of the two solid wastes is 1:2.33. The specific steps are as follows:

[0045] Step 1: Take the crushed MnZn ferrite magnetic core solid waste powder, and after washing, purifying, drying, sieving and other processes, a powder 1 with a particle size of about 1-75 μm is obtained.

[0046] Step 2: Take the crushed manganese zinc ferrite wave-absorbing solid waste powder, after washing, purifying, drying and other processes, add it to the ball mill tank according to the mass ratio of powder: water: ball milling beads: 1:1.5:8 In the process, wet ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com