Adaptive continuous phase hydraulic transmission oil pumping machine

A hydraulic transmission and self-adaptive technology, applied in the direction of production fluid, drilling equipment, wellbore/well components, etc., can solve the problems of parameter drift, underground reservoir heterogeneity, high system cost, etc., and achieve the effect of equipment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

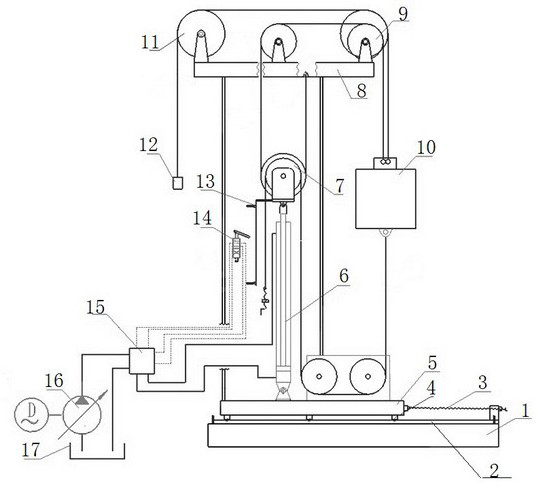

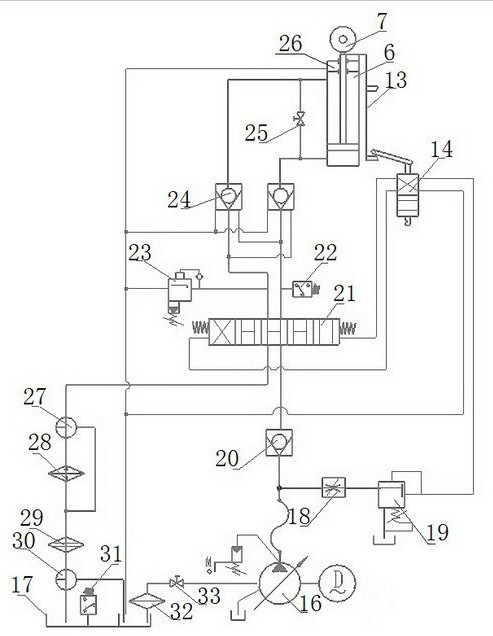

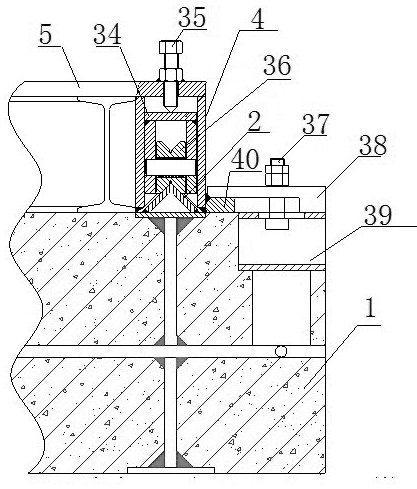

[0033] An adaptive continuous-phase hydraulic transmission pumping unit, such as figure 1 , figure 2 , image 3As shown, it comprises that the upper platform 8 is fixed on the base through a stand, and the vertical oil cylinder 6 is fixed on the base, and the movable pulley block 7 is connected to the end of the piston rod of the oil cylinder 6, and the upper and lower ropes connected by the rope tensioner pass through The fixed pulley 9 is connected to the balance box 10, and the transmission rope connected to the balance box 10 is connected to the rope hanger 12 matched with the oil well sucker rod through the rear pulley 11. The matched stroke controller 13, the adjustable base 5 is internally fitted with the roller box 34 installed through the lifting seat 4 which is evenly distributed on the left and right bottom frames, and the roller box 36 is matched with the corresponding ground angle steel guide rail 2, and is positioned on the left and right sides of the base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com