Method for improving mechanical property of 3D printing nickel-based superalloy through in-situ heat treatment

A nickel-based superalloy, 3D printing technology, applied in the direction of improving energy efficiency, process efficiency, additive processing, etc., can solve problems such as cracking and poor mechanical properties, shorten the process flow, improve shaping, and avoid cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co-13Cr-3.4Al-3.9Ti-3.8Mo-2.1W-2.4Ta-0.9Nb -0.05Zr-0.03B-0.04C-the balance is Ni.

[0042] Include the following steps:

[0043] (1) Preparation before laser 3D printing

[0044] Establish a three-dimensional CAD model on the computer according to the shape of the part; use software to slice and layer the model, and import it into the additive manufacturing system; first, dry the alloy powder in a vacuum drying oven at 120°C for 4 hours, then put it into the powder supply tank and carry out Spread powder, and pass inert gas into the working chamber until the oxygen content is lower than 100ppm.

[0045] (2) Laser 3D printing manufacturing

[0046] Through the numerical control system, the high-energy laser beam is used to scan the alloy powder in step (1) twice, and the laser beam of A1 power is scanned r...

Embodiment 2

[0055] The difference from Embodiment 1 is the scanning parameters of the laser 3D printing process twice in the step (2). The first laser scanning process parameters in step (2) are as follows: laser spot diameter is 70 μm, laser power is 200 W, laser scanning rate is 850 mm / s, laser scanning distance is 90 μm, and the powder layer thickness is 30 μm; the second laser scanning process parameters are as follows : The laser spot diameter is 90μm, the laser power is 30W, the laser scanning speed is 250mm / s, and the laser scanning spacing is 60μm.

[0056] Others are the same as in Embodiment 1.

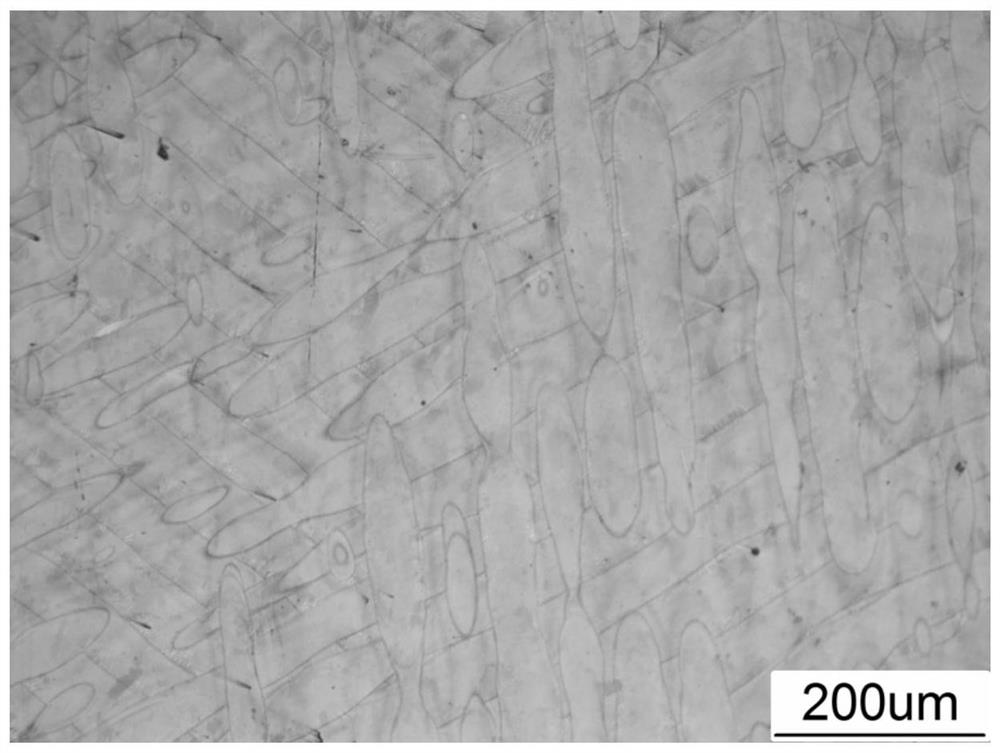

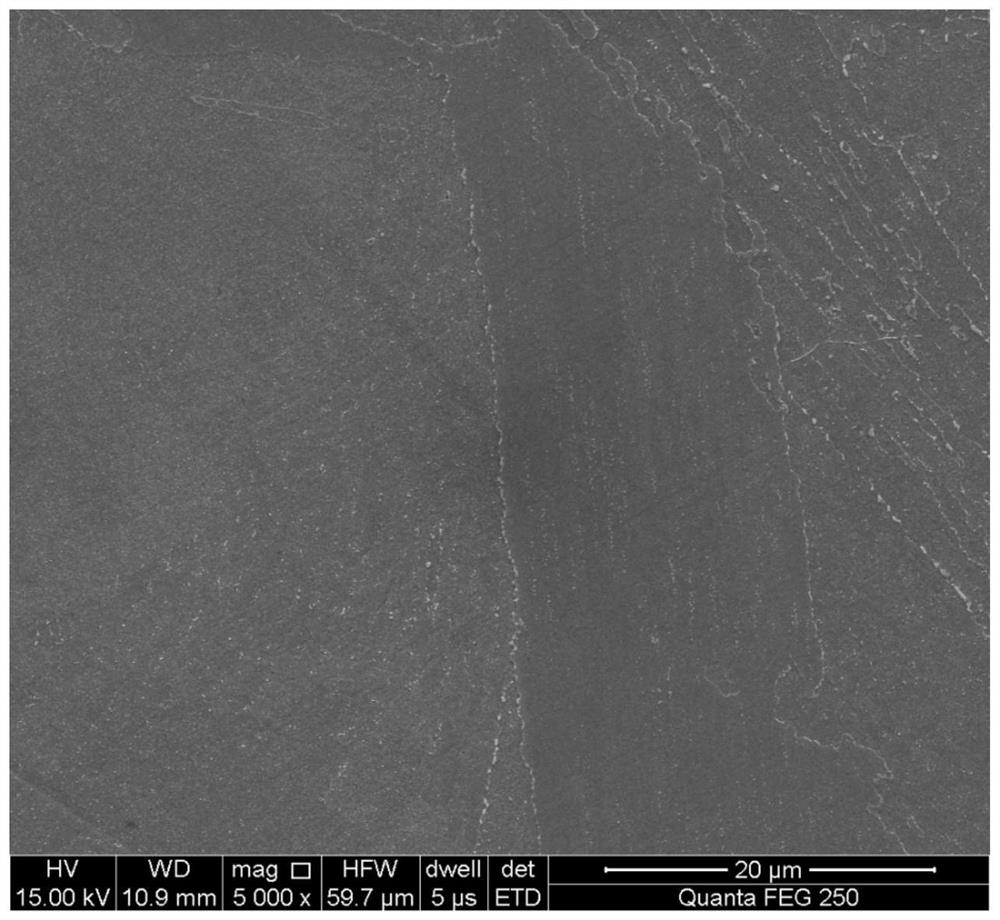

[0057] The prepared René 104 nickel-based superalloy has a compact structure and no cracks. After testing, the microhardness of the René 104 nickel-base superalloy prepared in Example 2 is 516HV 0.2 , Yield strength and tensile strength were 1017MPa and 1242MPa, elongation reached 11.1%.

Embodiment 3

[0059] The difference from Embodiment 1 is the scanning parameters of the laser 3D printing process twice in the step (2). The first laser scanning process parameters in step (2) are as follows: laser spot diameter is 70 μm, laser power is 225 W, laser scanning rate is 900 mm / s, laser scanning distance is 90 μm, and the powder layer thickness is 40 μm; the second laser scanning process parameters are as follows : Laser spot diameter is 100μm, laser power is 20W, laser scanning speed is 200mm / s, laser scanning spacing is 60μm.

[0060] Others are the same as in Embodiment 1.

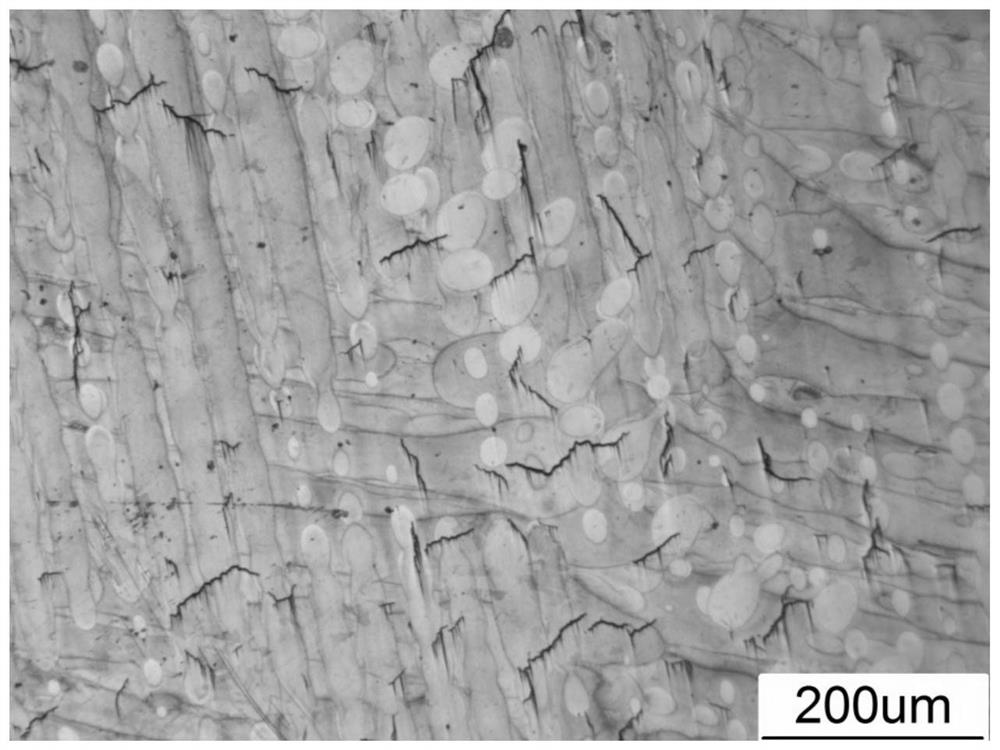

[0061] The prepared René 104 nickel-based superalloy has a compact structure and no cracks. After testing, the microhardness of the René 104 nickel-based superalloy prepared in Example 3 is 531HV 0.2 , Yield strength and tensile strength were 1025MPa and 1258MPa, elongation reached 10.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com