High-capacity high-nickel positive electrode material and preparation method thereof

A cathode material and high-capacity technology, which is applied in the field of high-capacity and high-nickel cathode materials and their preparation, can solve the problems of difficulty in meeting high-nickel cathode materials, many technological processes, and complicated operations, and is suitable for large-scale industrial production applications and processes. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

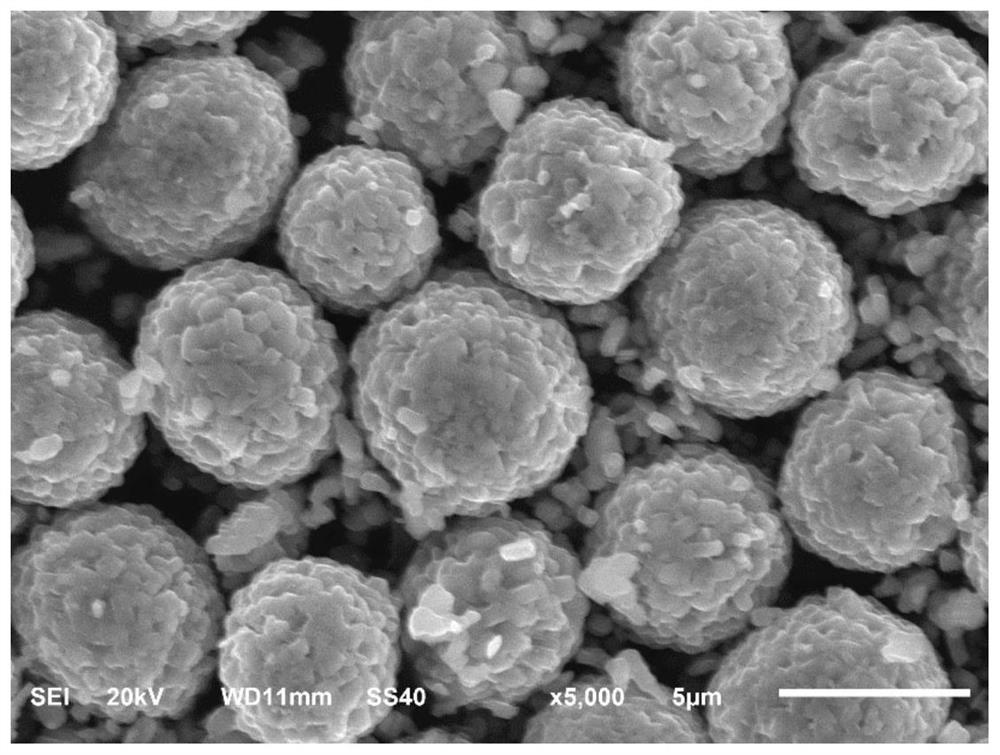

[0031] According to a preferred embodiment of the present invention, the high-nickel precursor is Ni x co y mn 1-x-y (OH) 2 , where, 0.8

[0032] In the present invention, the source of the high-nickel precursor is not particularly limited, and commercially available products well known to those skilled in the art are preferably used.

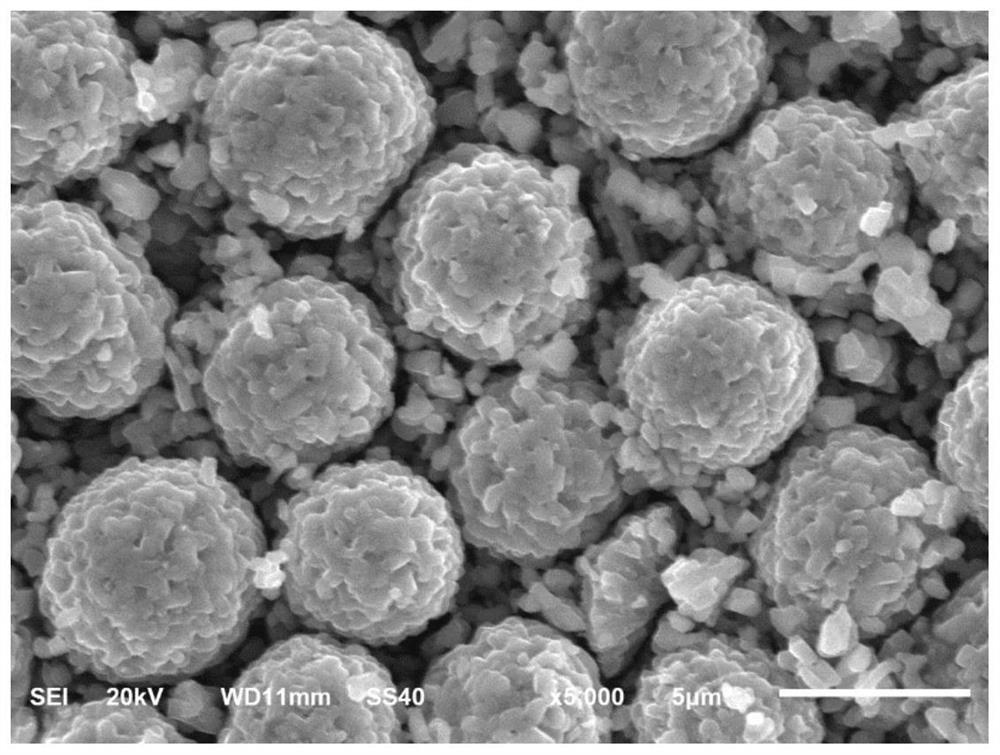

[0033] According to the present invention, the particle size of the high-nickel precursor is 1-10 μm, preferably 3-8 μm, more preferably 4-7 μm, such as 5 μm, and the positive electrode material obtained when the precursor particle size is too large is processed into the energy density of the battery Low; the cycle performance of the positive electrode material obtained by the precursor particle size is too small,

[0034] According to the present invention, the lithium-containing compound is selected from one or more of lithium-containing oxides, hydroxides, nitrates and carbonates, preferably LiOH, Li 2 CO 3 、LiNO 3 an...

Embodiment Embodiment 1

[0097] 500g high-nickel ternary precursor Ni 0.88 co 0.06 mn 0.06 (OH) 2 , 230.500g LiNO 3 , and 1.2540g of Al 2 o 3 , 0.4763g of TiO 2 The modified additives are mixed evenly;

[0098] The above mixture was sintered at 600°C for 15 hours in an oxygen atmosphere furnace. After cooling, the primary sintered material was obtained, which was pulverized, sieved with a 100-mesh screen, and then stirred and washed with deionized water. After suction filtration, it was placed in Dry in a vacuum oven at 250°C for 5 hours to obtain a high-nickel cathode material matrix;

[0099] 350g high-nickel cathode material matrix and 10.5g coating agent Co 3 o 4 well mixed;

[0100] The mixture of the high-nickel cathode material matrix and the coating agent was placed in an oxygen atmosphere furnace and sintered at 200° C. for 3 hours, and sieved with a 100-mesh sieve after cooling. A high-capacity high-nickel cathode material is obtained.

[0101] Gained high-capacity high-nickel po...

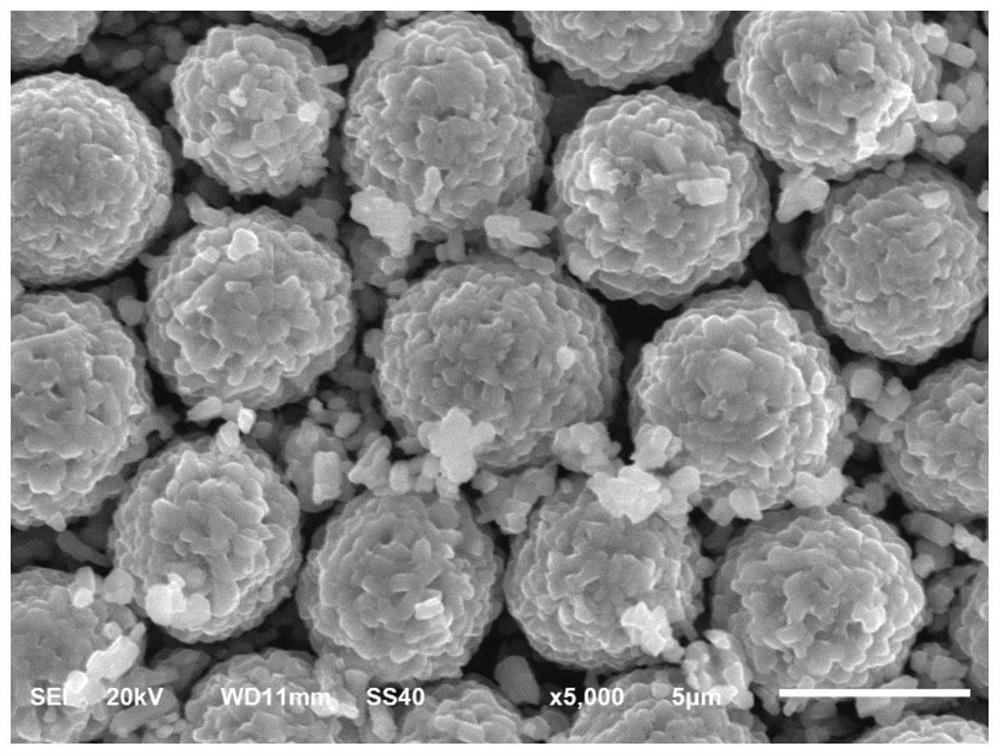

Embodiment 2

[0103] 500g high-nickel ternary precursor Ni 0.88 co 0.06 mn 0.06 (OH) 2 , 235.750gLiNO 3 , and 1.2540g of Al 2 o 3 , 0.4763g of TiO 2 The modified additives are mixed evenly;

[0104] The above mixture was sintered at 600°C for 15 hours in an oxygen atmosphere furnace. After cooling, the primary sintered material was obtained, which was pulverized, sieved with a 100-mesh screen, and then stirred and washed with deionized water. After suction filtration, it was placed in Dry in a vacuum oven at 250°C for 5 hours to obtain a high-nickel cathode material matrix;

[0105] 350g high-nickel cathode material matrix and 10.5g coating agent Co 3 o 4 well mixed;

[0106] The mixture of the high-nickel cathode material matrix and the coating agent was placed in an oxygen atmosphere furnace and sintered at 200° C. for 3 hours, and sieved with a 100-mesh sieve after cooling. A high-capacity high-nickel cathode material is obtained.

[0107] The obtained high-capacity high-nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com