A kind of Wo3 coated lithium manganese oxide material and preparation method thereof

A technology for coating lithium manganate and lithium heteromanganate, which is applied to structural parts, electrical components, battery electrodes, etc., to achieve the effects of improved deliquescence, uniform coating of precipitation reaction, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

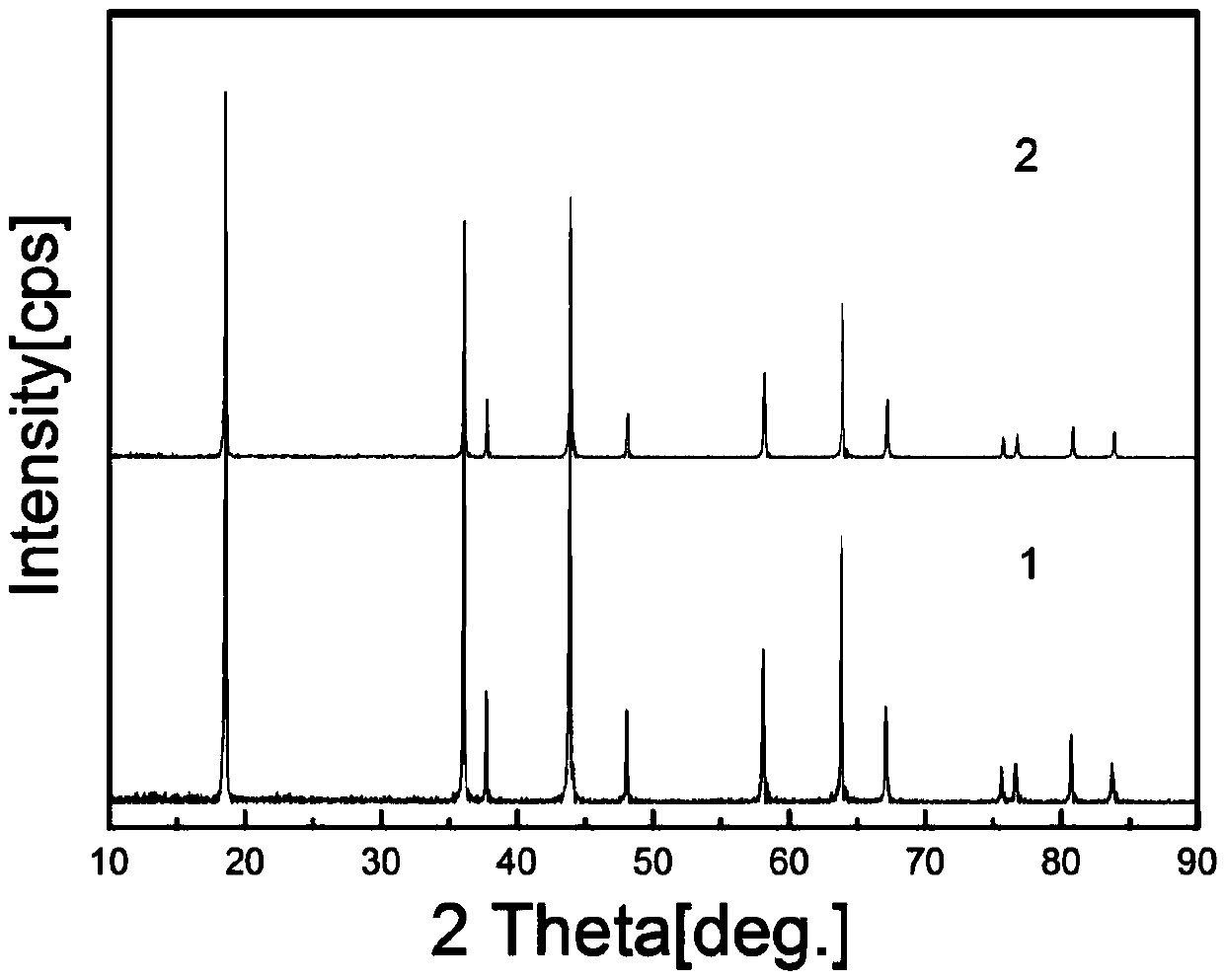

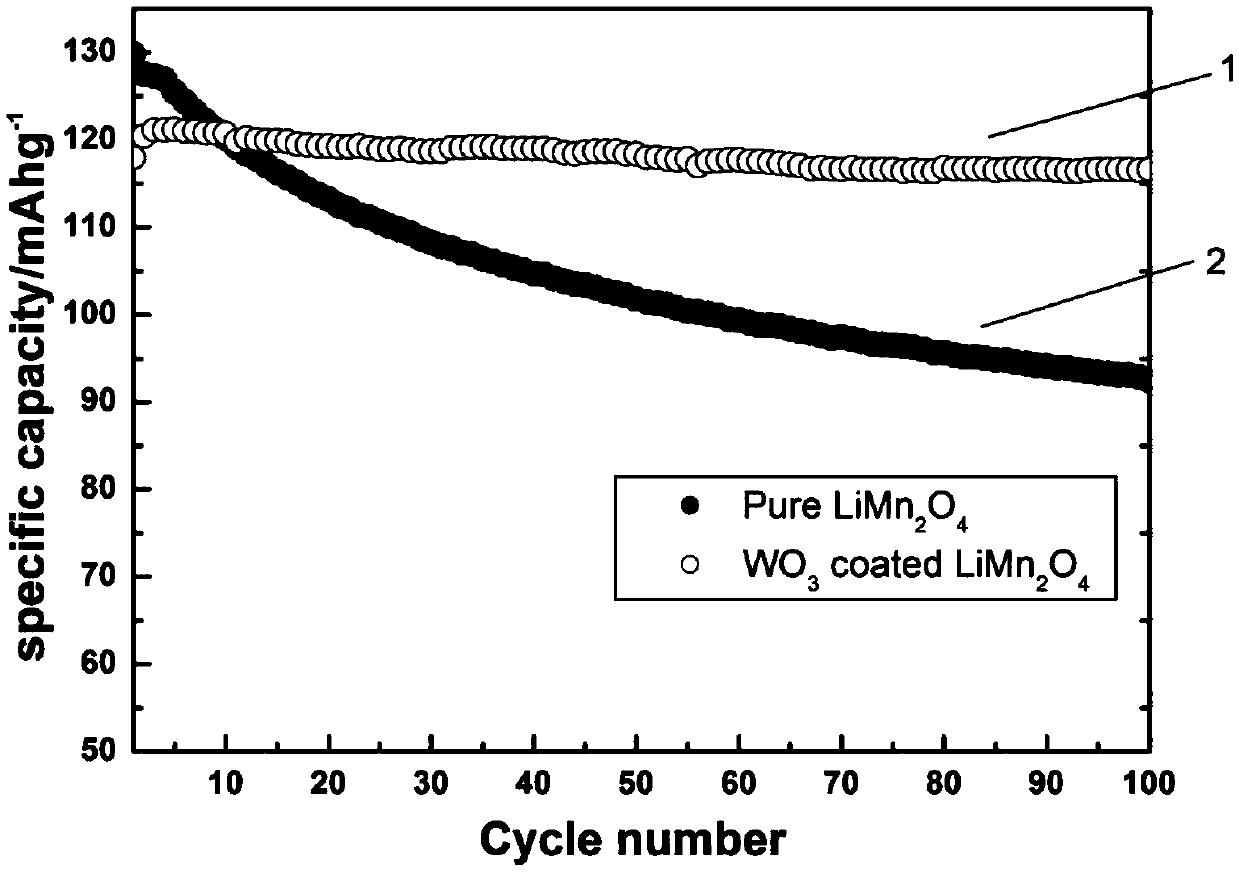

[0027] A kind of WO 3 Coating lithium manganate material to dope lithium manganate LiMn 1.96 Al 0.04 o 3.98 f 0.02 as the core, with WO 3 is the cladding layer, WO 3 Coated lithium manganese oxide material, WO 3 The content is 0.5%.

[0028] The WO 3 The preparation method of coated lithium manganese oxide material is:

[0029] (1) Preparation of doped lithium manganese oxide LiMn by high-temperature solid-state method 1.96 Al 0.04 o 3.98 f 0.02 : 3.92mol manganese dioxide, 0.98mol lithium carbonate, 0.04molAl 2 o 3 After mixing with 0.04molLiF, first raise the temperature to 650°C, sintering time 8h, then raise the temperature to 750°C, sintering time 15h;

[0030] (2) prepare the aqueous solution of ammonium tungstate, adjust the pH of the solution to be 8.0, the doped lithium manganate LiMn prepared in step (1) 1.96 Al 0.04 o 3.98 f 0.02 Add to the aqueous solution of ammonium tungstate, stir at 110°C for 6h;

[0031] (3) Sinter the mixture prepared in st...

Embodiment 2

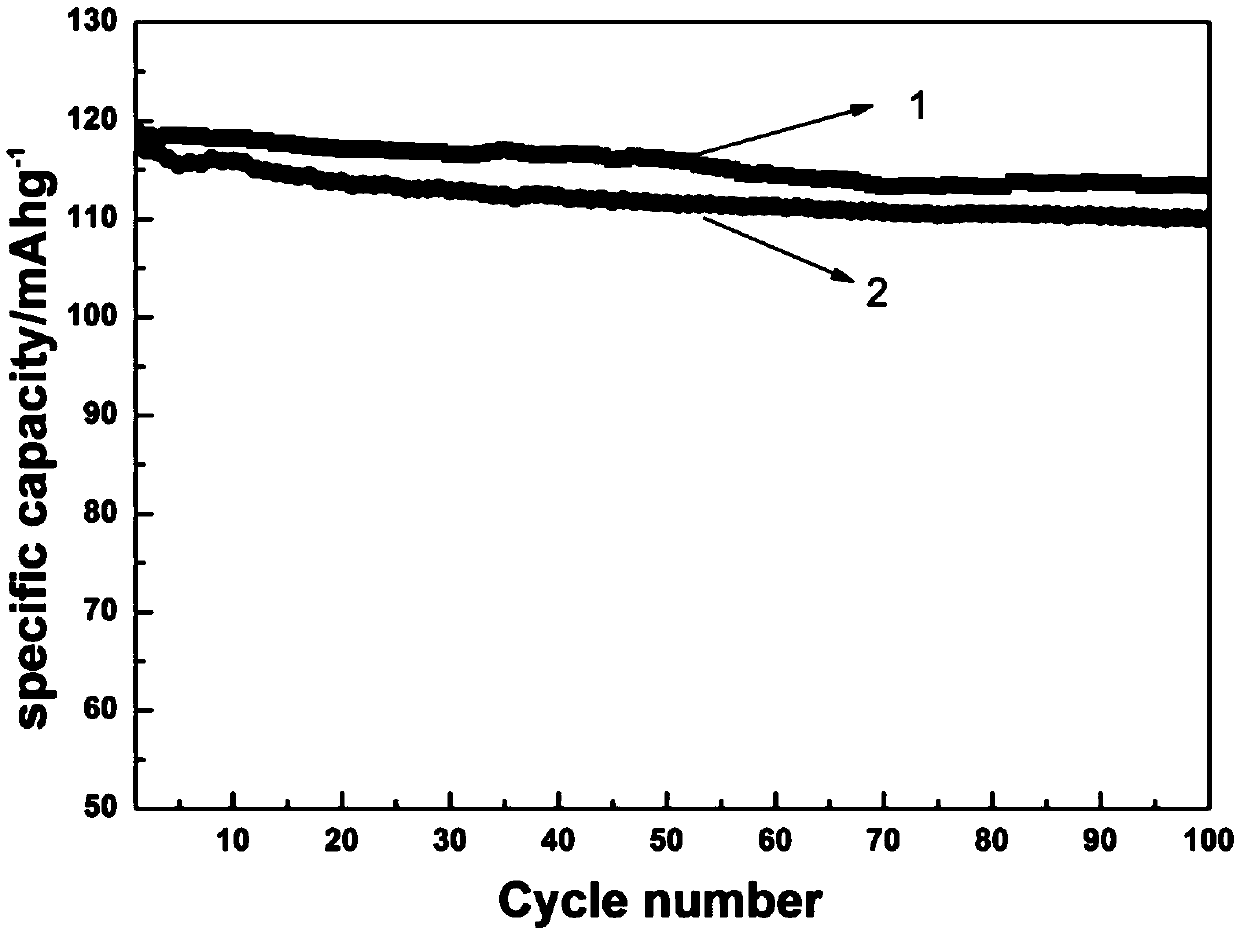

[0036] A kind of WO 3 Coating lithium manganate material to dope lithium manganate LiMn 1.98 Ga 0.02 o 3.97 f 0.03 as the core, with WO 3 is the cladding layer, WO 3Coated lithium manganese oxide material, WO 3 The content is 5%.

[0037] (1) Preparation of doped lithium manganese oxide LiMn by high-temperature solid-state method 1.98 Ga 0.02 o 3.97 f 0.03 : After mixing 3.96mol of manganese dioxide, 0.97mol of lithium carbonate, 0.02mol of gallium oxide and 0.06mol of lithium fluoride, first raise the temperature to 600°C for 10h of sintering time, then raise the temperature to 750°C for 30h of sintering time;

[0038] (2) prepare the aqueous solution of ammonium tungstate, adjust the pH of the solution to be 7.5, the doped lithium manganate LiMn prepared in step (1) 1.98 Ga 0.02 o 3.97 f 0.03 Add to the aqueous solution of ammonium tungstate, stir at 140°C for 2h;

[0039] (3) Sinter the mixture prepared in step (2) at 400°C for 3h and cool to obtain WO 3 Coa...

Embodiment 3

[0044] A kind of WO 3 Coating lithium manganate material to dope lithium manganate LiMn 1.93 Mg 0.07 o 3.98 Cl 0 . 02 as the core, with WO 3 is the cladding layer, WO 3 Coated lithium manganese oxide material, WO 3 The content is 0.8%.

[0045] (1) Preparation of doped lithium manganese oxide LiMn by high-temperature solid-state method 1.93 Mg 0.07 o 3.98 Cl 0.02 : After mixing 3.86mol of manganese dioxide, 1mol of lithium carbonate, 0.12mol of magnesium nitrate and 0.02mol of magnesium chloride, first raise the temperature to 700°C, sintering time 9h, then raise the temperature to 850°C, sintering time 8h;

[0046] (2) prepare the aqueous solution of ammonium tungstate, adjust the pH of the solution to be 7.3, the doped lithium manganate LiMn prepared in step (1) 1.93 Mg 0.07 o 3.98 Cl 0.02 Add to the aqueous solution of ammonium tungstate, stir at 120°C for 3h;

[0047] (3) Sinter the mixture prepared in step (2) at 450°C for 5h and cool to obtain WO 3 Coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com