Highly-integrated filtering system and using method

A filtration system and advanced technology, applied in the field of highly integrated filtration systems, can solve the problems of low integration, large space occupied by the filtration system, insufficient utilization of resources, etc., and achieve good filtration effect, low cost, and low equipment energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

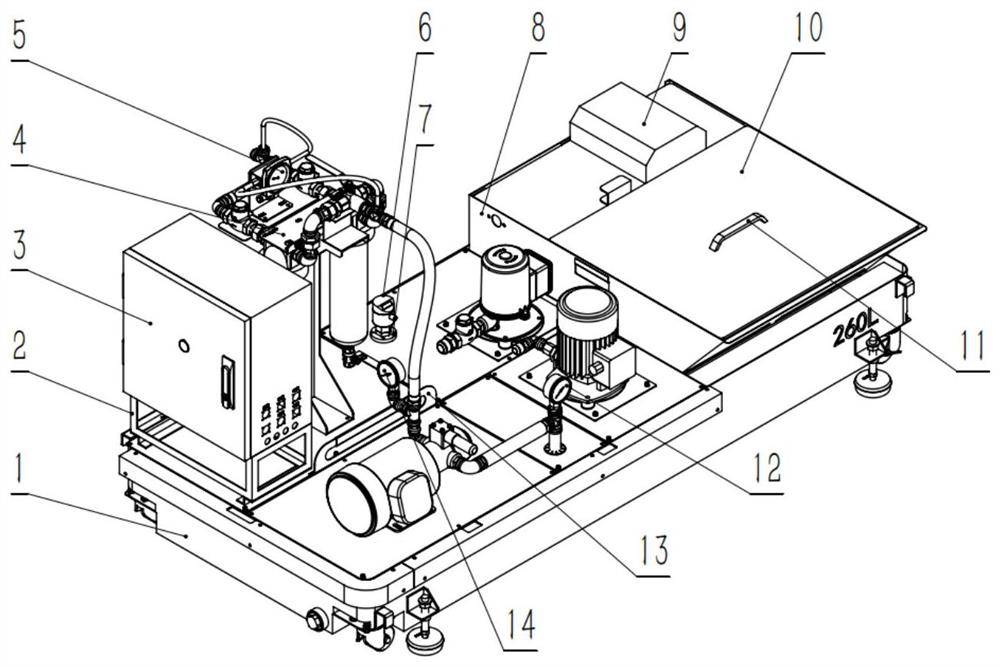

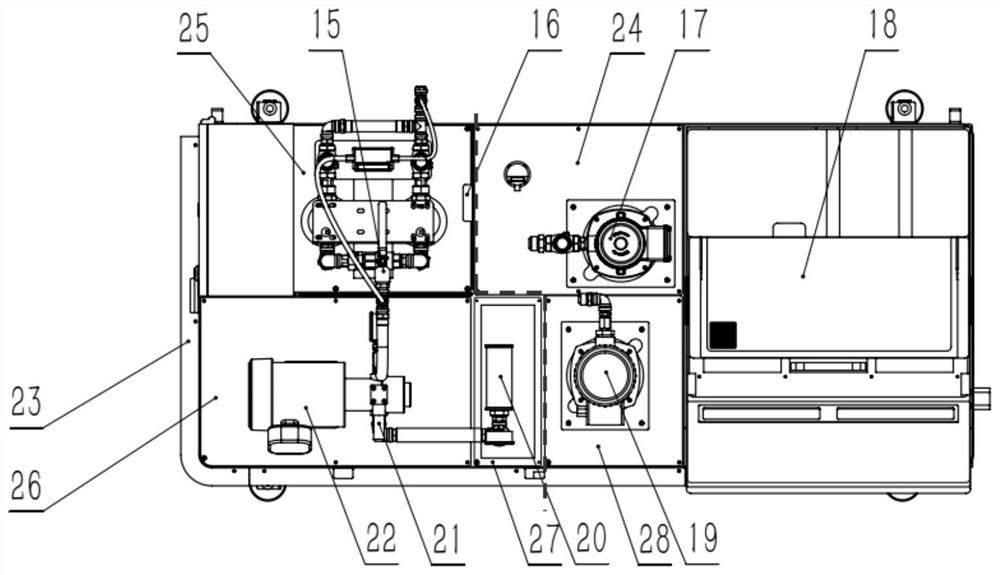

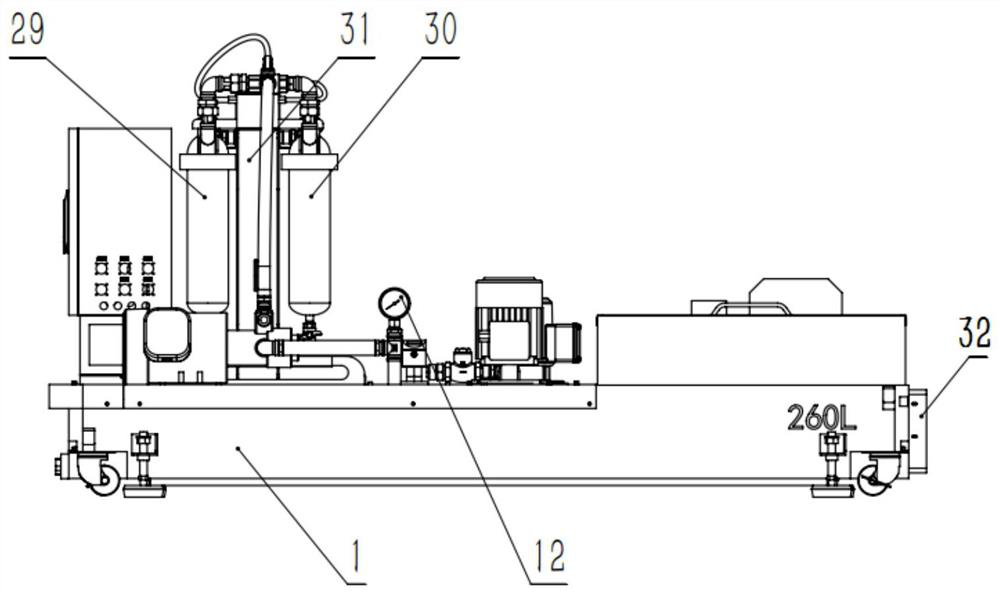

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

[0042] like Figure 1~2 As shown, a highly integrated filtration system disclosed by the present invention includes a water tank 1, a primary filtration unit, a cutting oil cooling pump assembly 17, a flushing pump assembly 19 and a pressurized filtration unit.

[0043] The water tank 1 is divided into an ordinary processing low-pressure area and a central water outlet high-pressure area, separated by the dotted line shown in the figure. The general processing low-pressure area is used to set the primary filter unit, the cutting oil cooling pump assembly 17 and the flushing pump assembly 19, and the central outlet high-pressure area is used to set the booster filter unit.

[0044] The peripheral equipment of the present invention is described by taking a machine tool as an example.

[0045] The primary filter unit adopts a filter basket 8 which is arranged above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com