Gas-liquid distribution system and process for absorbing flue gas based on cavitation machine coupling aid

A technology of gas-liquid distribution and gas-liquid distributor, which is applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of high cost of oxidant, low utilization rate, slow reaction rate, etc., and achieve high utilization rate of additives , The effect of simple device composition and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

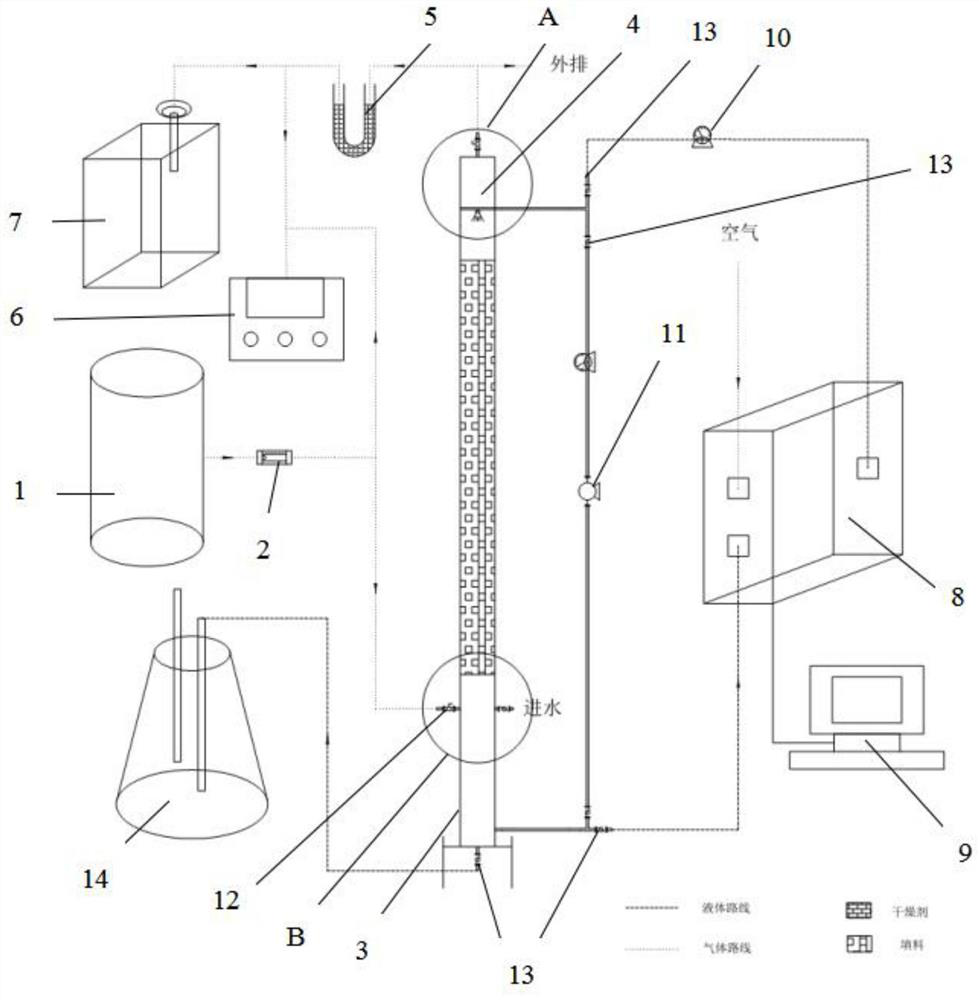

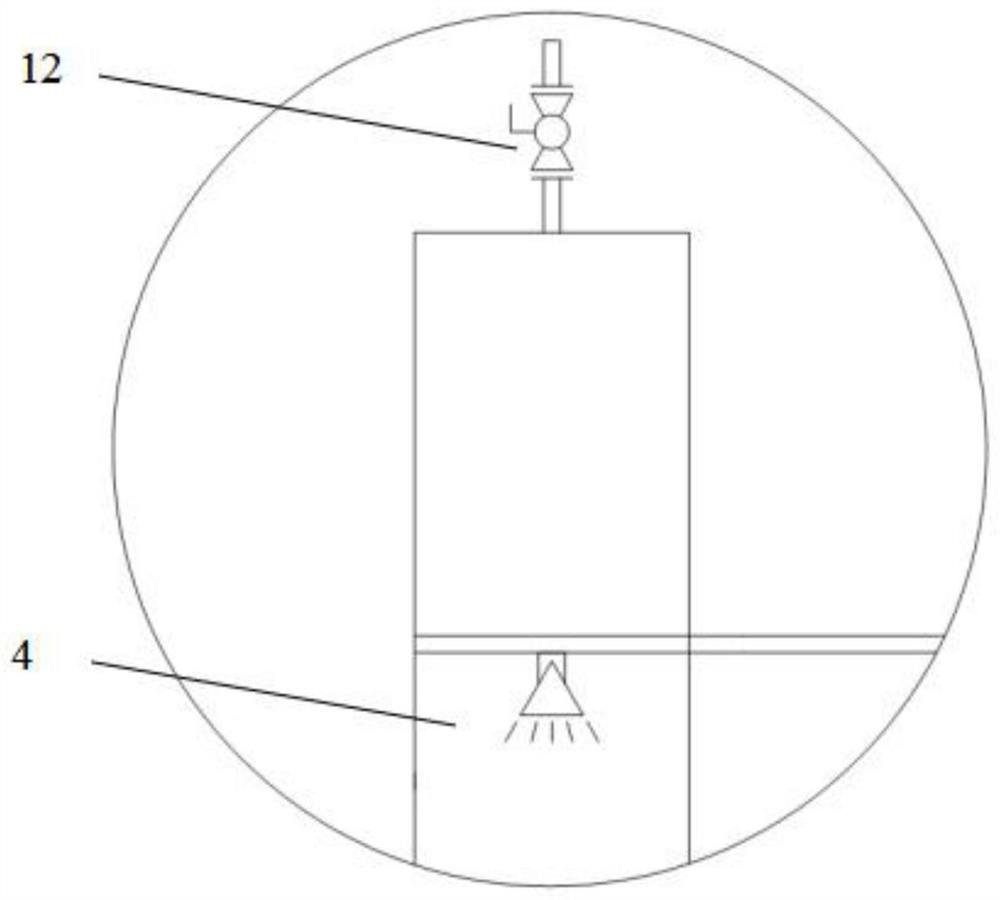

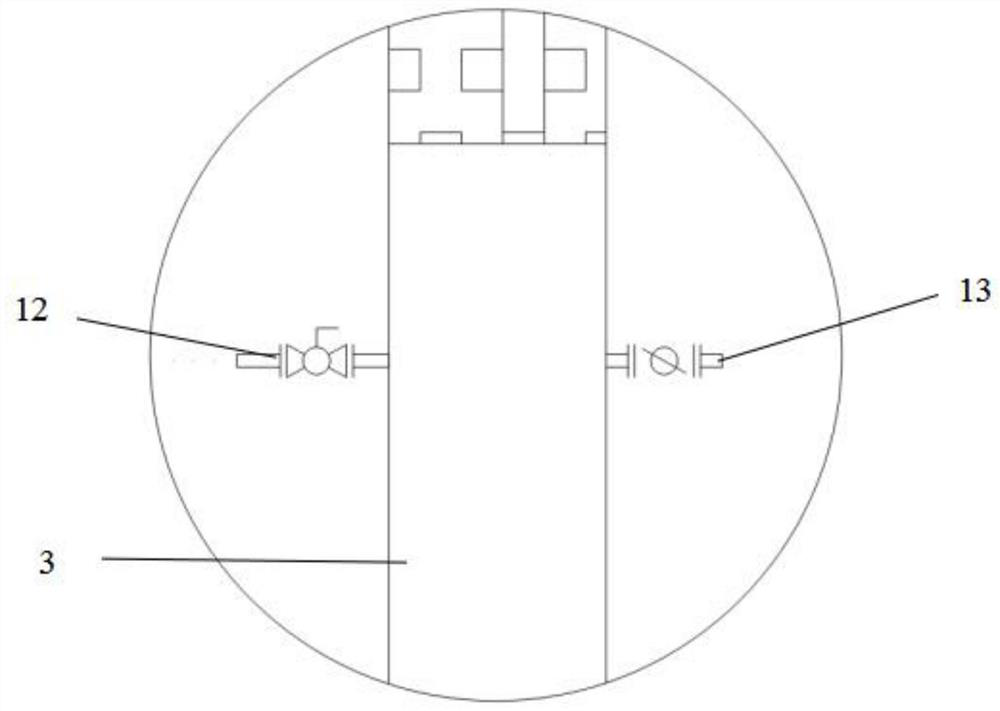

[0083] Such as Figure 1-3 As shown, the gas-liquid distribution system of the present invention is assembled and the air-tightness and water-tightness of the device are checked.

[0084] Choose boiler flue gas as the gas source, the concentration of SO2 is 900ppm, the concentration of NO is 300ppm, the concentration of HC is 150ppm, and the concentration of particulate matter is 71.2mg / m3.

[0085] Put MnSO4·4H2O and FeSO4·7H2O into the absorption liquid to make the concentration 2mmol / L, put NaCl and SDS into the absorption liquid so that the mass concentrations of NaCl and SDS in the absorption liquid are respectively 0.7g / L and 4mg / L .

[0086] Control the intake flow rate of absorption tower 3 to 500m3 / h, the flow rate of liquid distributor 4 to 2t / h, wherein the flow rate from cavitation machine 8 is 1.5t / h, and the circulation flow rate of absorption liquid is 0.5t / h.

[0087] Control the pH of the feed water in the lower part of the absorption tower 3 of the additive...

Embodiment 2

[0090] Such as Figure 1-3 As shown, the gas-liquid distribution system of the present invention is assembled and the air-tightness and water-tightness of the device are checked.

[0091] Choose boiler flue gas as the gas source, the concentration of SO2 is 1000ppm, the concentration of NO is 400ppm, the concentration of HC is 200ppm, and the concentration of particulate matter is 75.7mg / m3.

[0092] Put MnSO4·4H2O and FeSO4·7H2O into the absorption liquid to make the concentration 2mmol / L, put NaCl and SDS into the absorption liquid so that the mass concentrations of NaCl and SDS in the absorption liquid are respectively 0.7g / L and 4mg / L .

[0093] Control the intake flow rate of absorption tower 3 to 500m3 / h, the flow rate of liquid distributor 4 to 2t / h, wherein the flow rate from cavitation machine 8 is 1.5t / h, and the circulation flow rate of absorption liquid is 0.5t / h.

[0094] Control the pH of the feed water in the lower part of the absorption tower 3 of the additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com