A method and application of electrospinning to prepare zirconium-loaded pan composites

A technology of electrospinning and composite materials, which is applied in the field of catalyst preparation and biomass catalytic conversion, which can solve the problems of complex metal and organic acid catalytic systems, high cost of precious metals that are not suitable for industrial production, and large catalyst loss, etc., to achieve a reaction system Green, cheap and easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

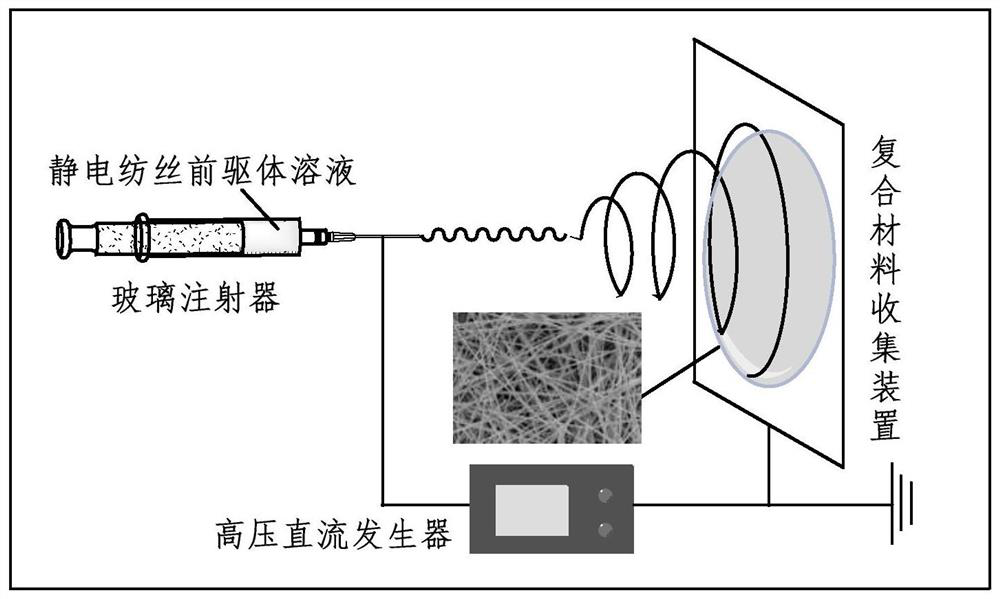

[0025] A method for preparing zirconium-loaded PAN composite material (Zr@PAN) by electrospinning, specifically comprising the following steps:

[0026] (1) Add 2.25g of polyacrylonitrile into 40mL of DMF, the molecular weight of polyacrylonitrile is 150,000, stir at 25°C for 30 minutes to dissolve, and the stirring speed is 400rpm to obtain a polyacrylonitrile solution;

[0027] (2) 2.65gZr(NO 3 ) 4 ·5H 2 O is added in the polyacrylonitrile solution that step (1) obtains, and ultrasonic dispersion is uniform, and the power of ultrasonic dispersion is 25kHz, and the time is 5 minutes, obtains mixed solution;

[0028] (3) Put the mixed solution obtained in step (2) into an oil bath and heat and stir. The temperature of the oil bath is 65°C, the time is 1 hour, and the stirring speed is 18rpm, so that the solution is fully mixed and evenly obtained to obtain the electrospinning precursor solution ;

[0029] (4) Electrospinning the electrospinning precursor solution gained in...

Embodiment 2

[0032] A method for preparing zirconium-loaded PAN composite material (Zr@PAN) by electrospinning, specifically comprising the following steps:

[0033] (1) Add 2.25g of polyacrylonitrile into 40mL of DMF, the molecular weight of polyacrylonitrile is 150,000, stir at 26°C for 30 minutes to dissolve, and the stirring speed is 350rpm to obtain a polyacrylonitrile solution;

[0034] (2) 1.18gZr(NO 3 ) 4 ·5H 2 O is added in the polyacrylonitrile solution that step (1) obtains, and ultrasonic dispersion is uniform, and the power of ultrasonic dispersion is 20kHz, and the time is 10 minutes, obtains mixed solution;

[0035] (3) Put the mixed solution obtained in step (2) into an oil bath and heat and stir. The temperature of the oil bath is 70°C, the time is 1 hour, and the stirring speed is 20 rpm, so that the solution is fully mixed and evenly obtained to obtain the electrospinning precursor solution ;

[0036] (4) Electrospinning the electrospinning precursor solution obtaine...

Embodiment 3

[0039] A method for preparing zirconium-loaded PAN composite material (Zr@PAN) by electrospinning, specifically comprising the following steps:

[0040] (1) Add 2.25g of polyacrylonitrile into 40mL of DMF, the molecular weight of polyacrylonitrile is 150,000, stir at 20°C for 30 minutes to dissolve, and the stirring speed is 400rpm to obtain a polyacrylonitrile solution;

[0041] (2) 4.54gZr(NO 3 ) 4 ·5H 2 O is added in the polyacrylonitrile solution that step (1) obtains, and ultrasonic dispersion is uniform, and the power of ultrasonic dispersion is 22kHz, and the time is 7 minutes, obtains mixed solution;

[0042] (3) Put the mixed solution obtained in step (2) into an oil bath and heat and stir. The temperature of the oil bath is 80°C, the time is 1 hour, and the stirring speed is 15rpm, so that the solution is fully mixed and evenly obtained to obtain the electrospinning precursor solution ;

[0043] (4) Electrospinning the electrospinning precursor solution obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com