Preparation method of lutetium nitrate feed liquid

A technology of lutetium nitrate and feed liquid is applied in the preparation/processing of rare earth metal compounds, rare earth metal nitrate and other directions, which can solve the problems of high chloride ion and sodium ion content, complicated production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

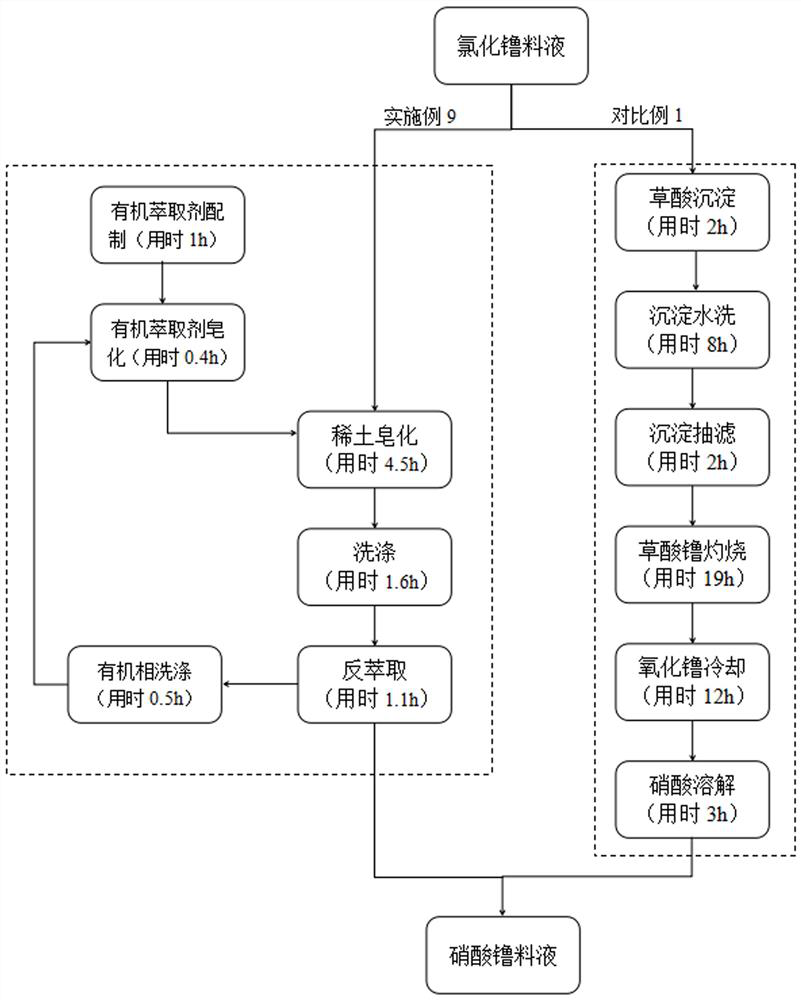

Image

Examples

Embodiment 1

[0052] A preparation method for lutetium nitrate feed liquid, it comprises the steps:

[0053] (1) Preparation of organic extractant: Mix naphthenic acid, octanol, and kerosene uniformly to obtain an organic extractant, wherein the volume ratio of naphthenic acid: octanol: kerosene is 1:1:2;

[0054] (2) Saponification of the organic extractant: add a sodium hydroxide solution with a concentration of 6 mol / L to the organic extractant obtained in step (1), then carry out the saponification reaction under shaking conditions for 15 minutes, and control to obtain a saponification degree of 0.40 organic extractant;

[0055] (3) Rare earth saponification: Rare earth saponification is carried out in a cascade reaction, which includes the first stage extraction section, 4 intermediate extraction sections and the final extraction section in series, and the flow rate of the organic phase in each extraction section is 25L / min, the flow rate ratio of the organic phase to the aqueous pha...

Embodiment 2

[0081] A preparation method for lutetium nitrate feed liquid, it comprises the steps:

[0082] (1) Preparation of organic extractant: Mix naphthenic acid, octanol, and kerosene uniformly to obtain an organic extractant, wherein the volume ratio of naphthenic acid: octanol: kerosene is 1:1:2;

[0083] (2) Saponification of the organic extractant: add a sodium hydroxide solution with a concentration of 6 mol / L to the organic extractant obtained in step (1), then carry out the saponification reaction under shaking conditions for 10 minutes, and control to obtain a saponification degree of 0.42 organic extractant;

[0084] (3) Rare earth saponification: Rare earth saponification is carried out in a cascade reaction, including the first stage extraction section, 2 intermediate extraction sections and the final stage extraction section in series, and the flow rate of the organic phase in each extraction section is 25L / min, the flow rate ratio of the organic phase to the aqueous ph...

Embodiment 3

[0108] A preparation method for lutetium nitrate feed liquid, it comprises the steps:

[0109] (1) Preparation of organic extractant: Mix naphthenic acid, octanol, and kerosene uniformly to obtain an organic extractant, wherein the volume ratio of naphthenic acid: octanol: kerosene is 1:1:2;

[0110] (2) Saponification of the organic extractant: add a sodium hydroxide solution with a concentration of 6 mol / L to the organic extractant obtained in step (1), then carry out the saponification reaction under shaking conditions for 12 minutes, and control to obtain a saponification degree of 0.45 organic extractant;

[0111] (3) Rare earth saponification: Rare earth saponification is carried out in a cascade reaction, including the first stage extraction section, 6 intermediate extraction sections and the final stage extraction section in series, and the flow rate of the organic phase in each extraction section is 30L / min, the flow rate ratio of the organic phase to the aqueous ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com