A green and environment-friendly water-reducing agent and recycled concrete using the water-reducing agent

A green, environmentally friendly, water-reducing agent technology, applied in the field of concrete and its admixtures, can solve the problems of weak water-reducing effect of ultra-fine-grained cement, and achieve the effects of improving segregation and bleeding, improving dispersibility, and good synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

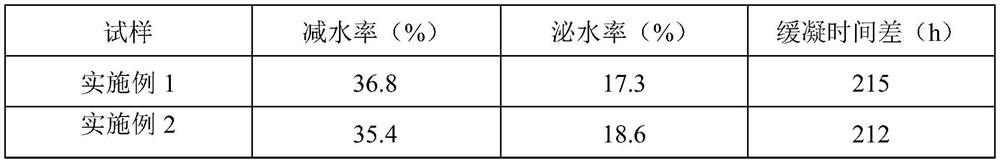

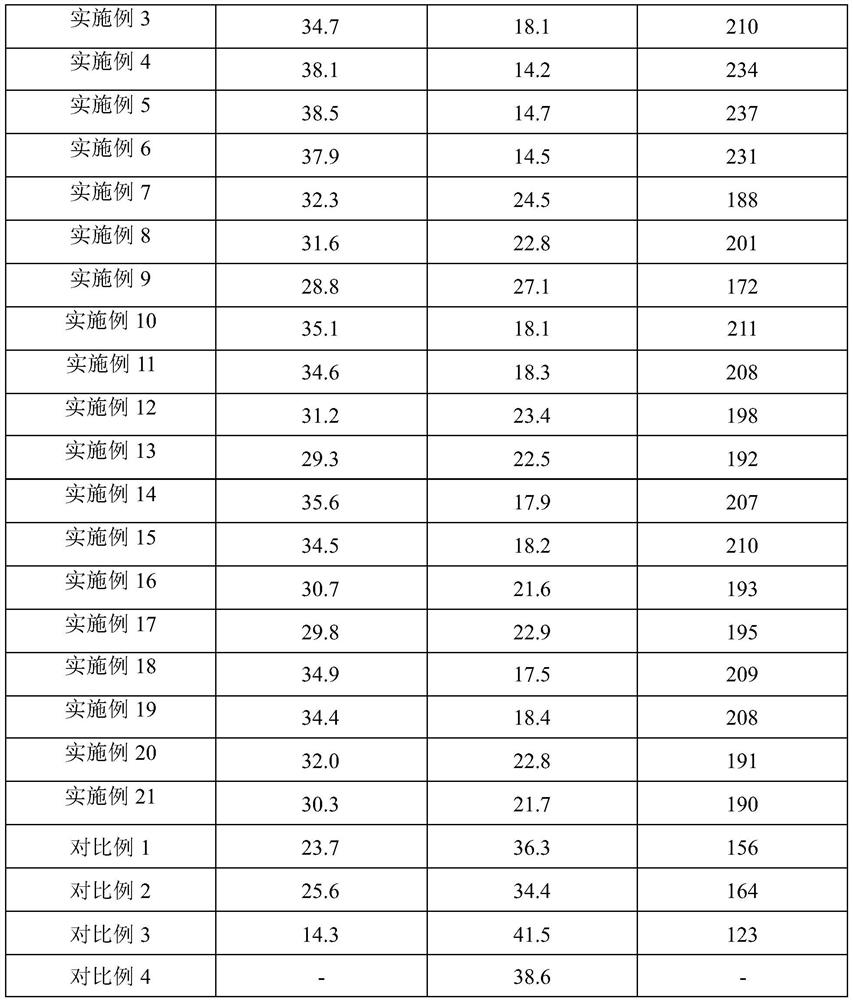

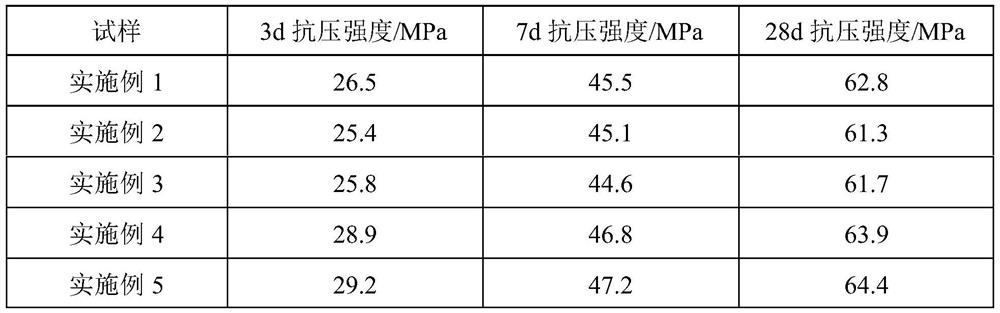

Examples

Embodiment 1

[0038] The water reducer is made of the following components by weight: 65 parts of sulfamate-based water reducer, 20 parts of hydroxypropyl methylcellulose, 10 parts of triisopropanolamine, and 10 parts of 2-hydroxyethylamine And 5 parts of anhydrous sodium metasilicate;

[0039] The preparation method of sulfamate-based water reducer is:

[0040] 1) Preparation of raw materials: Prepare sodium p-aminobenzenesulfonate, phenol, urea, sodium pyrophosphate and formaldehyde raw materials, wherein the molar ratio of sodium p-aminobenzenesulfonate, phenol and formaldehyde is 1:1.5:2.75, (p-aminobenzenesulfonate The molar ratio of sodium sulfonate+phenol) to urea is 1:0.1, and the molar ratio of urea to sodium pyrophosphate is 1:0.86;

[0041] 2) heating to dissolve sodium p-aminobenzenesulfonate, phenol, urea and sodium pyrophosphate in deionized water, and stir evenly to obtain a solution;

[0042] 3) Slowly add formaldehyde dropwise to the solution, condense at a constant tempe...

Embodiment 2

[0052] The water reducer is made of the following components by weight: 55 parts of sulfamate-based water reducer, 15 parts of hydroxypropyl methylcellulose, 5 parts of triisopropanolamine, and 5 parts of 2-hydroxyethylamine And 2 parts of anhydrous sodium metasilicate;

[0053] The preparation method of sulfamate-based water reducer is:

[0054] 1) Preparation of raw materials: prepare sodium p-aminobenzenesulfonate, phenol, urea, sodium pyrophosphate and formaldehyde raw materials, wherein the molar ratio of sodium p-aminobenzenesulfonate, phenol and formaldehyde is 1:1.25:2.75, (p-aminobenzene The molar ratio of sodium sulfonate+phenol) to urea is 1:0.05, and the molar ratio of urea to sodium pyrophosphate is 1:0.75;

[0055] 2) heating to dissolve sodium p-aminobenzenesulfonate, phenol, urea and sodium pyrophosphate in deionized water, and stir evenly to obtain a solution;

[0056] 3) Slowly add formaldehyde dropwise to the solution, condense at constant temperature for ...

Embodiment 3

[0066] The water reducer is made of the following components by weight: 75 parts of sulfamate-based water reducer, 25 parts of hydroxypropyl methylcellulose, 15 parts of triisopropanolamine, and 15 parts of 2-hydroxyethylamine And 8 parts of anhydrous sodium metasilicate;

[0067] The preparation method of sulfamate-based water reducer is:

[0068] 1) Raw material preparation: prepare sodium p-aminobenzenesulfonate, phenol, urea, sodium pyrophosphate and formaldehyde raw materials, wherein the molar ratio of sodium p-aminobenzenesulfonate, phenol and formaldehyde is 1:1.75:2.75, (p-aminobenzene The molar ratio of sodium sulfonate+phenol) to urea is 1:0.15, and the molar ratio of urea to sodium pyrophosphate is 1:1;

[0069] 2) heating to dissolve sodium p-aminobenzenesulfonate, phenol, urea and sodium pyrophosphate in deionized water, and stir evenly to obtain a solution;

[0070] 3) Slowly add formaldehyde dropwise to the solution, condense at constant temperature for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com