Post-tensioning prestressed concrete beam pore high-strength grouting agent

A post-tensioned prestressed concrete beam technology, which is applied in the field of post-tensioned prestressed beam channel grouting agent for concrete, which can solve the problems that the anti-corrosion and expansion performance requirements cannot be met, and the grouting agent cannot achieve zero bleeding. , to achieve the effect of low cost, easy operation and high strength grouting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

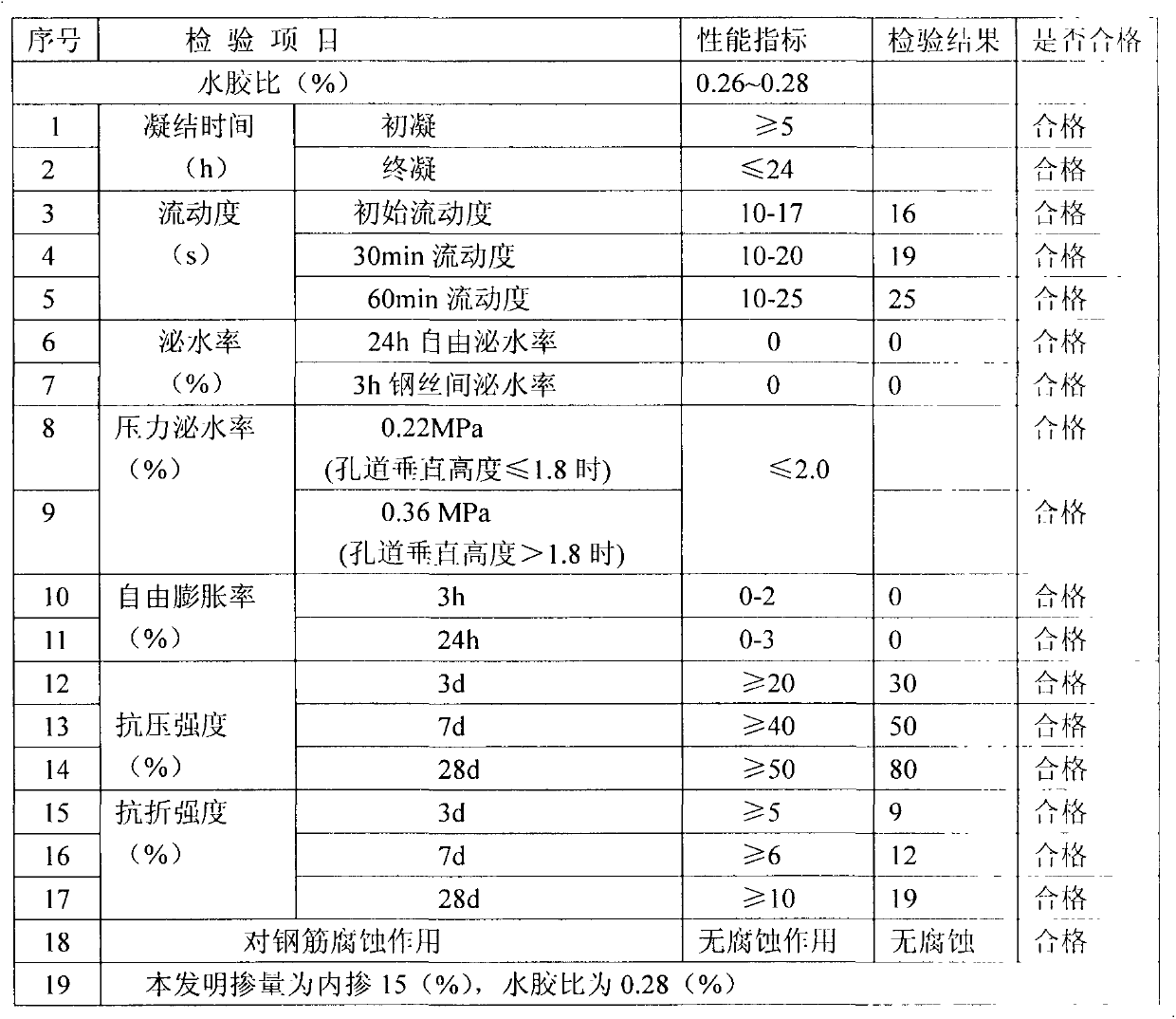

Examples

Embodiment 1

[0041] The purpose of this embodiment is to achieve the minimum water-reducing effect, meet the engineering crack prevention, low-cost grouting agent that resists carbonation and chlorine salt erosion, and the components are as follows by weight %:

[0042] Polycarboxylate superplasticizer 2%, polyacrylonitrile fiber 3%, superfine active micropowder 6%, methyl-based polymer 0.3%, high-durability mineral admixture 50%, citric acid 0.2%, rosin 0.5%, oxidation Magnesium 38%.

[0043] The above-mentioned components are crushed into granules that can be put into the grinder, mixed evenly, and the mixed material is ground until the particle size reaches 300-500 mesh, and then mixed with polyacrylonitrile fibers to prepare the A-type channel grouting agent.

[0044] How to use type A hole grouting agent:

[0045] method 1:

[0046] The above-mentioned present invention is by cement and water ratio:

[0047] 1. Grouting agent 0.45KG cement 2.55KG water 0.78KG (water-binder ratio: 0...

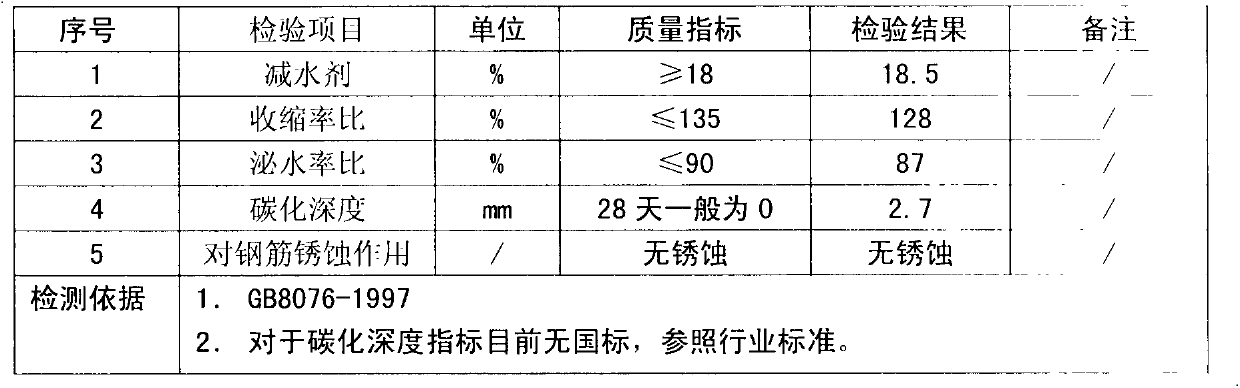

Embodiment 2

[0054] The purpose of this example is to achieve a good water-reducing effect, and at the same time meet the high engineering crack resistance, anti-carbonization degree and chlorine salt corrosion resistance of the grouting agent. The components are as follows by weight %: polycarboxylate water reducer 11 %, 5% polypropylene fiber, 10% ultrafine active micropowder, 0.3% methyl-based polymer, 35% high-durability mineral admixture, 0.2% citric acid, 0.5% rosin, and 38% magnesium oxide.

[0055] The above-mentioned components are broken into grindable granules, mixed evenly, and the mixed material is ground until the particle size reaches 300-500 mesh, and then mixed with polyacrylonitrile fibers to obtain a B-type channel grouting agent.

[0056] The B-type pore grouting agent is best to use the third method recommended above. The following is the test result of using the third method in cement:

[0057] Its performance indicators are as follows:

[0058]

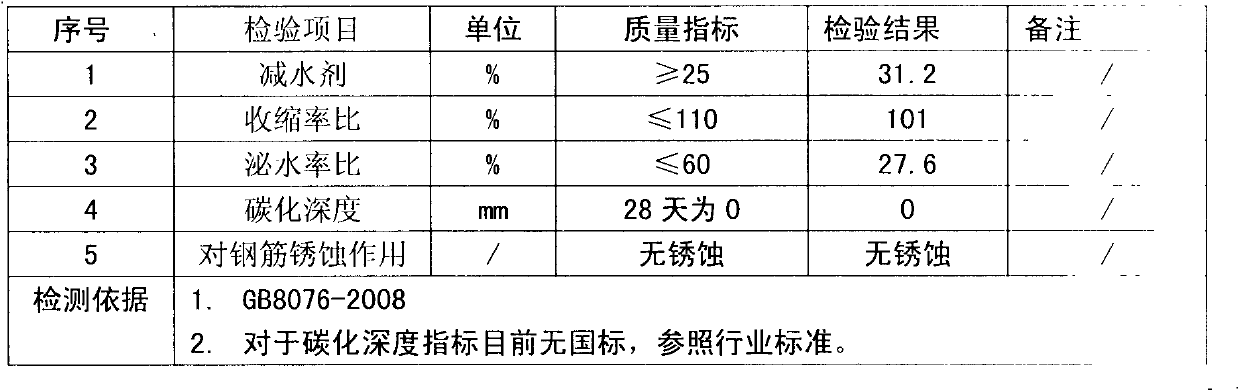

Embodiment 3

[0060] The purpose of this example is to achieve a medium water-reducing effect, and at the same time meet the high engineering crack resistance, anti-carbonization degree and chlorine salt corrosion resistance of the grouting agent. The components are as follows by weight %: polycarboxylate water reducer 6 %, 5% polypropylene fiber, 8% superfine active micropowder, 0.3% methyl-based polymer, 45% high-durability mineral admixture, 0.2% citric acid, 0.5% rosin, and 35% magnesium oxide.

[0061] The above-mentioned components are broken into granules that can be fed into the grinder, mixed evenly, and the mixed material is ground until the particle size reaches 300-500 mesh, and then mixed with polyacrylonitrile fibers to prepare a C-type channel grouting agent.

[0062]The C-type pore grouting agent is best to use the third method recommended above. The following is the test result of using the third method in cement:

[0063] Its performance indicators are as follows:

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com