Waterproof protection construction method

A construction method and technology of waterproof materials, applied in the field of waterproof engineering, can solve the problems of easy aging, poor puncture resistance and aging resistance, short life, etc., and achieve the effect of avoiding leakage and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

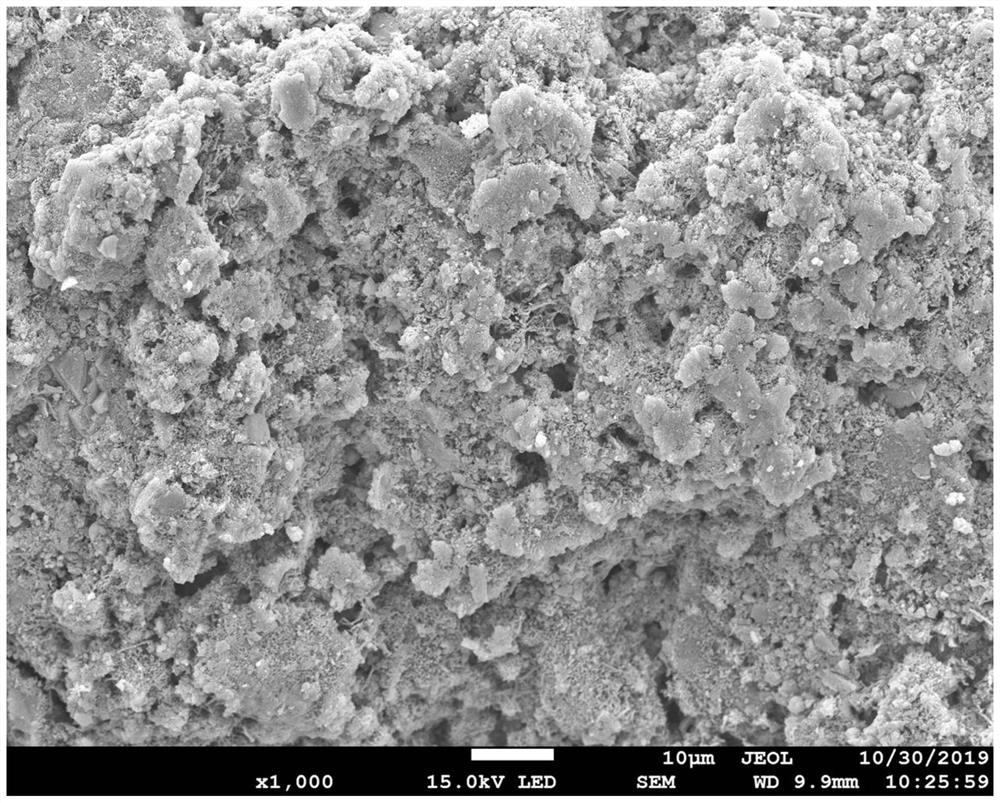

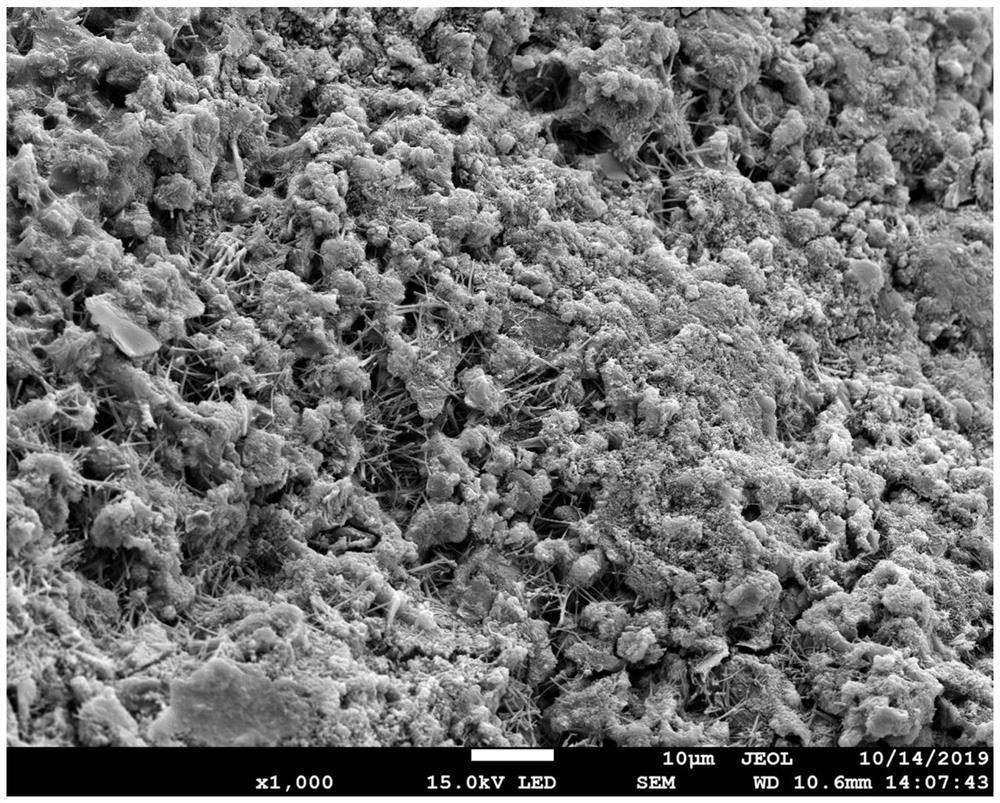

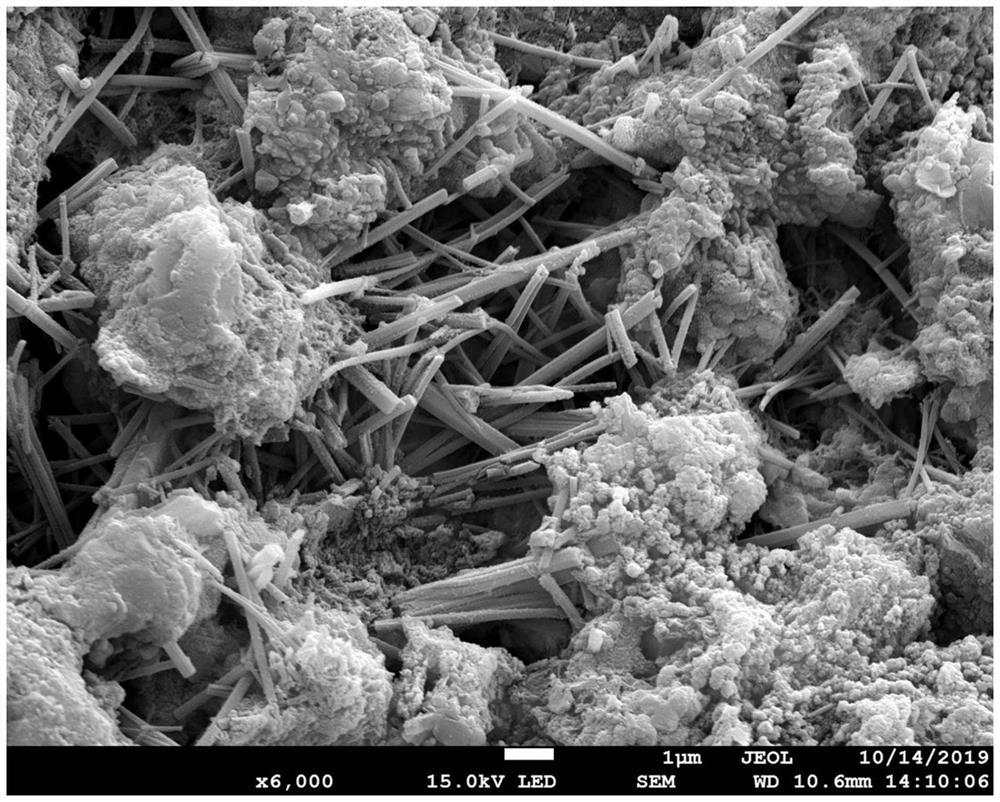

Image

Examples

Embodiment 1

[0038] 1. Weigh each raw material component according to parts by weight:

[0039] Nano-calcium silicate dispersion (10% solid content): 10 parts;

[0040] Sodium silicate solution (30% solid content): 10 parts;

[0041] Silica sol (30% solid content): 5 parts;

[0042] Sodium hydroxide: 3 parts;

[0043] Water: 72 parts;

[0044] Penetrant JFC: 0.1 parts.

[0045] During preparation, first mix sodium silicate with water to obtain a mixed solution; then dissolve sodium hydroxide in the mixed solution to obtain a secondary mixed solution; add weighed silica sol, nano-silicon Calcium acid dispersion and wetting and penetrating agent JFC are mixed to obtain a waterproof material.

[0046] 2. During waterproof construction, spray a sufficient amount of water on the surface of the cement substrate to make it wet. After the surface of the cement substrate has no clear water, spray the first waterproof material evenly; 4 hours after the first waterproof material is sprayed Afte...

Embodiment 2

[0049] 1. Weigh each raw material component according to parts by weight:

[0050] Nano-calcium silicate dispersion (15% solid content): 15 parts;

[0051] Sodium silicate solution (30% solid content): 20 parts;

[0052] Silica sol (30% solid content): 7 parts;

[0053] Sodium hydroxide: 4 parts;

[0054] Water: 54 parts;

[0055] Penetrant JFC: 0.2 parts.

[0056]During preparation, first mix sodium silicate with water to obtain a mixed solution; then dissolve sodium hydroxide in the mixed solution to obtain a secondary mixed solution; add weighed silica sol, nano-silicon Calcium acid dispersion and wetting and penetrating agent JFC are mixed to obtain a waterproof material.

[0057] 2. During waterproof construction, spray a sufficient amount of water on the surface of the cement substrate to make it wet. After the surface of the cement substrate has no clear water, spray the first waterproof material evenly; 4 hours after the first waterproof material is sprayed After...

Embodiment 3

[0059] 1. Weigh each raw material component according to parts by weight:

[0060] Nanometer calcium silicate dispersion (solid content 20%): 15 parts;

[0061] Sodium silicate solution (30% solid content): 30 parts;

[0062] Silica sol (30% solid content): 5 parts;

[0063] Sodium hydroxide: 3 parts;

[0064] Water: 47 parts;

[0065] Penetrant JFC: 0.3 parts.

[0066] During preparation, first mix sodium silicate with water to obtain a mixed solution; then dissolve sodium hydroxide in the mixed solution to obtain a secondary mixed solution; add weighed silica sol, nano-silicon Calcium acid dispersion and wetting and penetrating agent JFC are mixed to obtain a waterproof material.

[0067] 2. During waterproof construction, spray a sufficient amount of water on the surface of the cement substrate to make it wet. After the surface of the cement substrate has no clear water, spray the first waterproof material evenly; 4 hours after the first waterproof material is sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com