Compound and organic electroluminescent device

A compound and group technology, applied in the field of compounds and organic electroluminescent devices, can solve the problems of backward panel manufacturing enterprises and insufficient development of organic electroluminescent materials, and achieve improved lifespan, improved lifespan and luminous efficiency, and improved efficiency. and stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

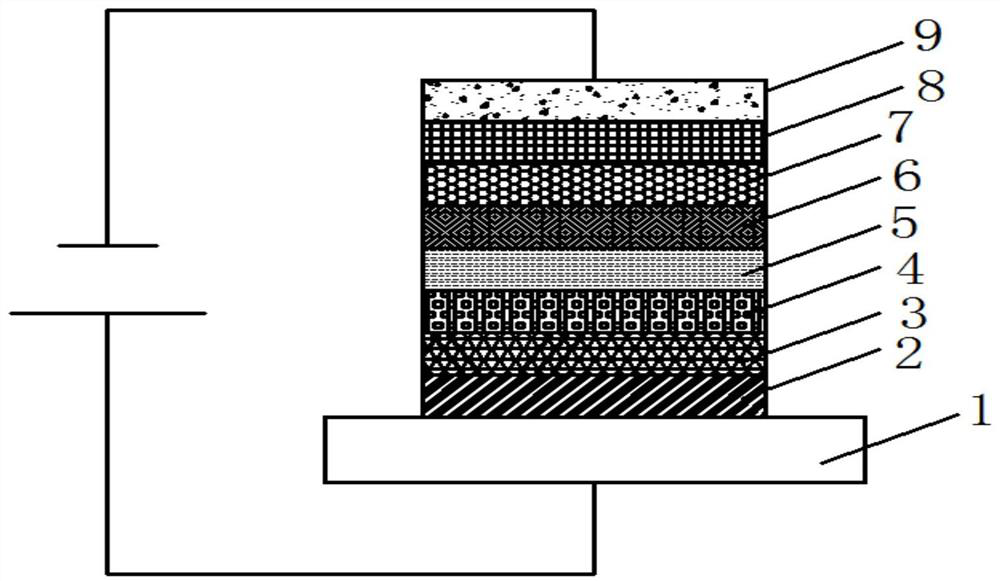

Method used

Image

Examples

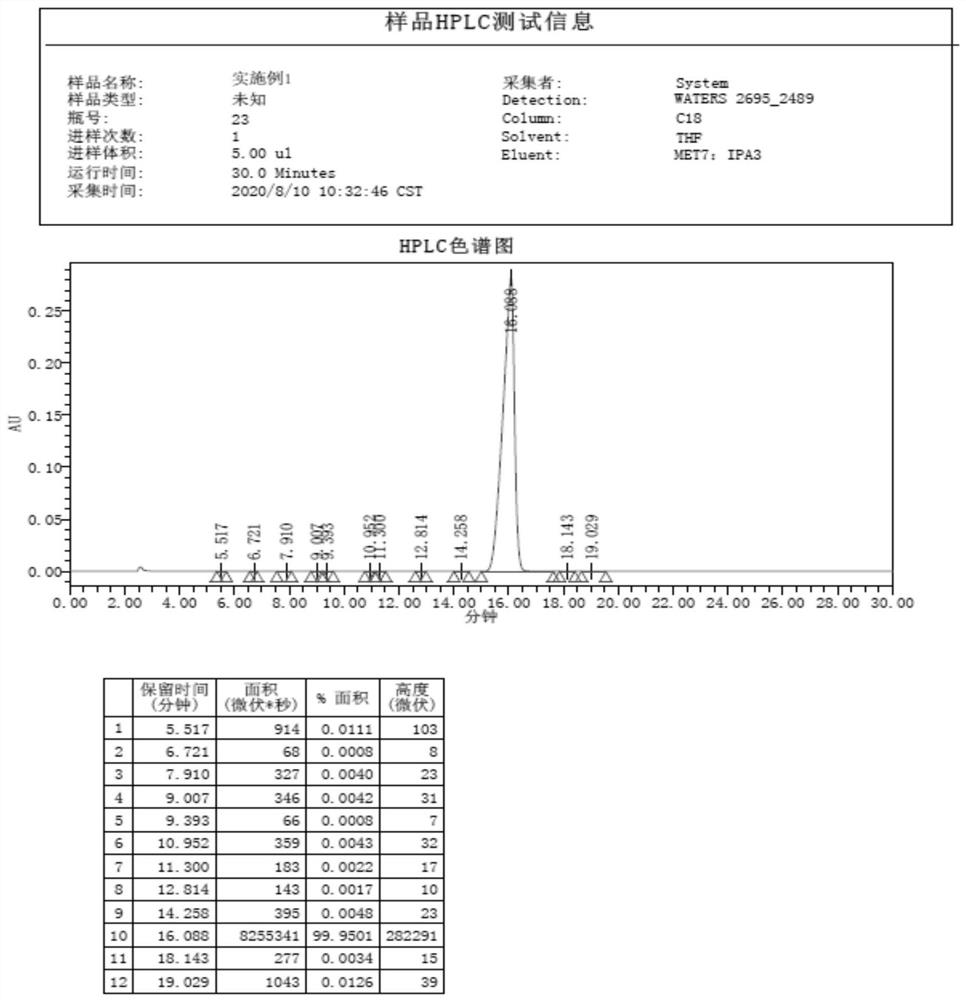

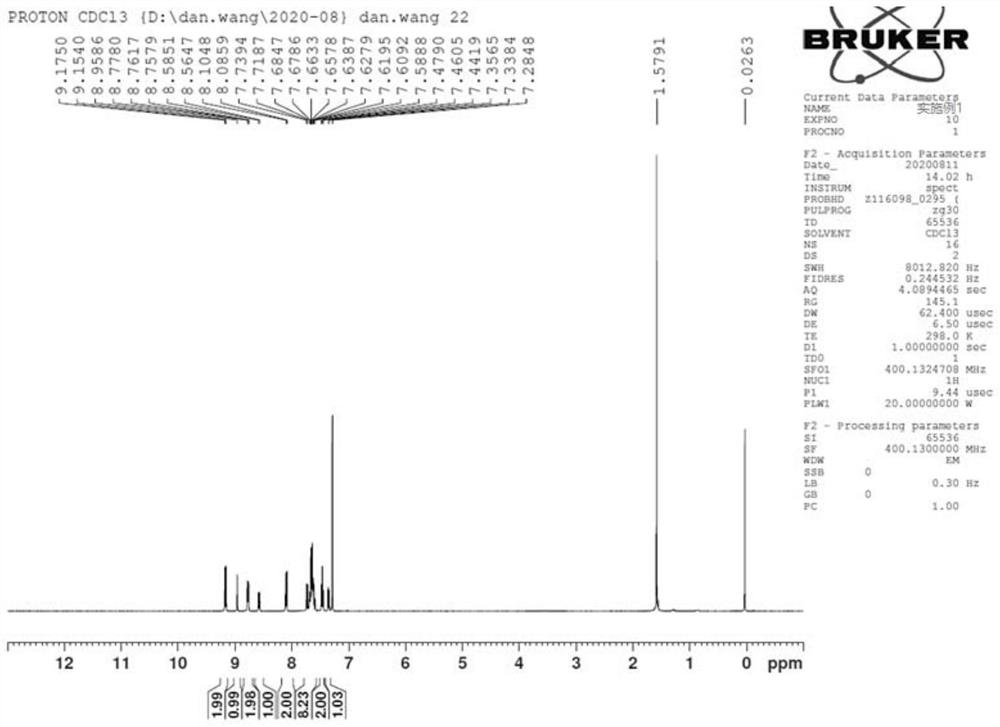

Embodiment 1

[0067]

[0068] The preparation method of compound 1 is as follows:

[0069]

[0070] Under nitrogen protection, compound 1-a (10g, 356.81g / mol, 28.03mmol), compound 1-b (1.1eq, 9.04g, 293.14g / mol, 30.83mmol) and sodium carbonate (2eq, 5.94g, 105.99 g / mol, 56.06mmol) was added to toluene (200ml), ethanol (100ml), water (100ml), stirred and mixed and then added tetrakis triphenylphosphine palladium (0.05eq, 1.62g, 1155.58g / mol, 1.4 mmol), warming up to reflux reaction for 10h, cooling to room temperature and adding water (100ml), stirring to separate the water phase, after the water phase was extracted with dichloromethane, after the organic phase was combined and dried with anhydrous sodium sulfate, the sample was mixed with silica gel column chromatography Purified to obtain compound 1 (12.79g, yield 80.1%), ESI-MS (m / z) (M+): theoretical value 569.66, measured value 570.19, elemental analysis results (molecular formula C39H19D5N4O): theoretical value C, 82.23; H N, 9....

Embodiment 2

[0075]

[0076] The preparation method of compound 2 is as follows:

[0077]

[0078] The preparation method is basically the same as in Example 1, the difference is that compound 1-a and compound 1-b are replaced by compound 2-a and compound 2-b respectively, and the reaction obtains compound 2 (yield 79.7%), ESI-MS (m / z)(M+): theoretical value 569.66, measured value 570.44, elemental analysis results (molecular formula C39H19D5N4O): theoretical value C, 82.23; H, 5.13; N, 9.84; O, 2.81; measured value C, 82.23; H, 5.13 ; N, 9.84; O, 2.81.

Embodiment 3

[0080]

[0081] The preparation method of compound 3 is as follows:

[0082]

[0083] The preparation method is basically the same as in Example 2, the difference is that compound 3-a is used to replace compound 2-a, and the reaction gives compound 3 (yield 80.5%), ESI-MS (m / z) (M+): theoretical value 572.68, The measured value is 572.81, and the elemental analysis result (molecular formula C39H16D8N4O): theoretical value C, 81.79; H, 5.63; N, 9.78; O, 2.79; measured value C, 81.79; H, 5.63; N, 9.78;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com