a kind of ag 3 po 4 /α-fe 2 o 3 Preparation methods and applications of composite materials

A technology of composite materials and reactors, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as poor stability, high cost, and large-scale application limitations, and achieve high photoluminescence The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

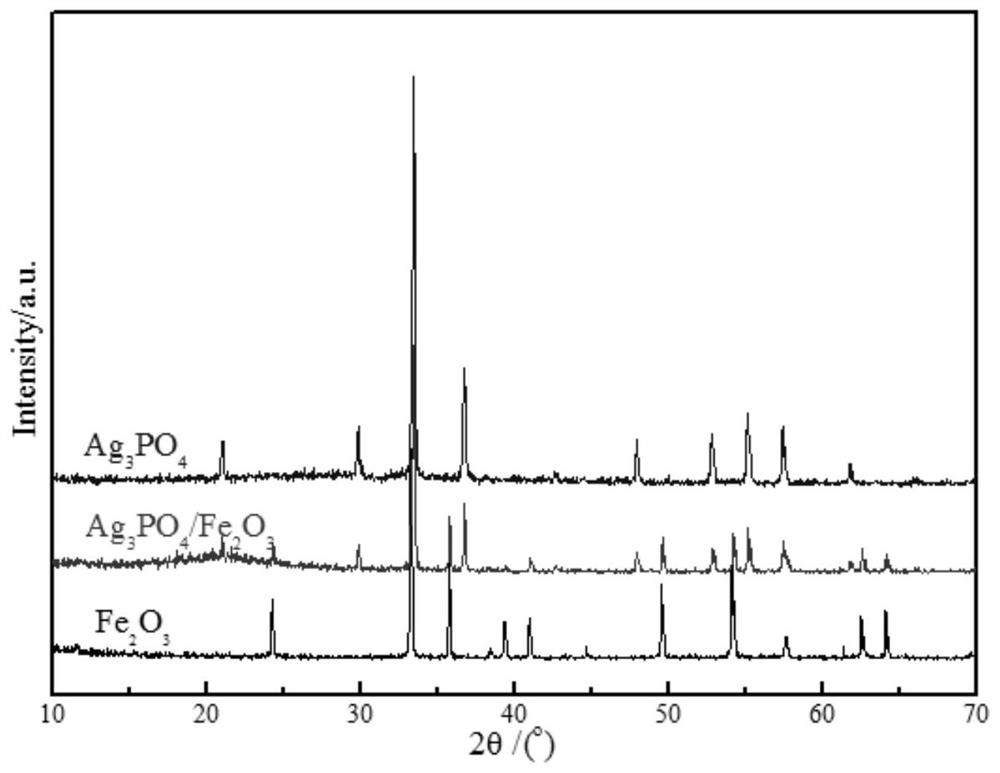

[0034] ①、Ag 3 PO 4 Preparation of powder:

[0035] Take 0.25g of AgNO 3 Dissolve in 60 mL of ionized water, add 0.5 g of polyvinylpyrrolidone, and sonicate for 5 min to obtain solution A. Take 0.19g of Na 2 HPO 4 Dissolved in 60 mL of ionized water and sonicated for 5 min to obtain solution B. Under stirring at 75°C in the dark, solution B was added dropwise to solution A, and after the dropwise addition was completed, the reaction was continued in the dark for 30 min. The obtained product was centrifuged, washed twice with deionized water and ethanol, and dried under vacuum at 60 °C to obtain Ag 3 PO 4 powder.

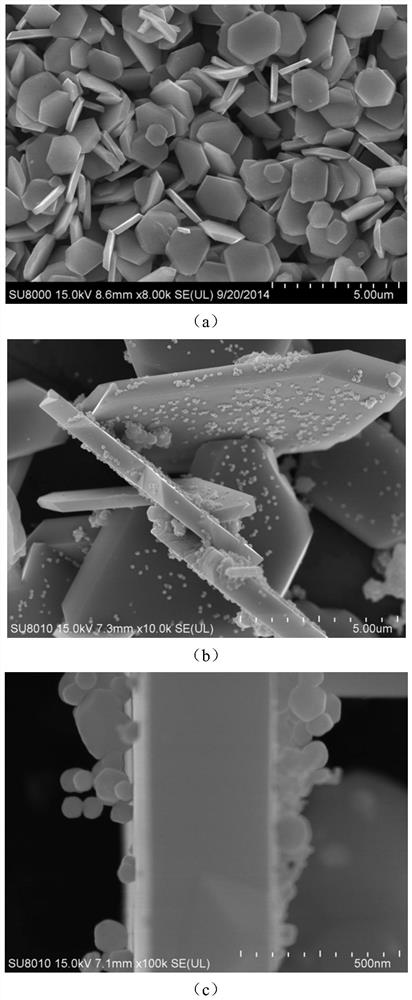

[0036] ②, flaky α-Fe 2 O 3 Preparation of:

[0037] Take 1.42g of FeCl 3 ·6H 2 O, add 60 mL of deionized water, add 2 g of NaOH after dissolving, and stir to obtain the precursor, which is placed in the reaction kettle for hydrothermal reaction at 180 ° C for 24 hours, and after the reaction kettle is cooled to room temperature, the product is washed with...

Embodiment 2

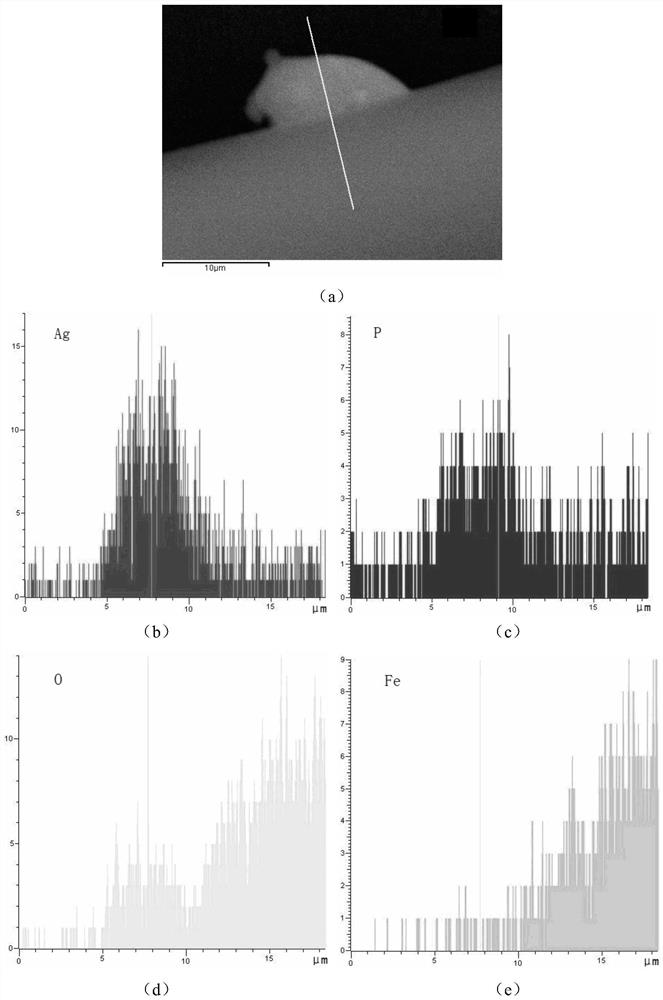

[0050] Ag 3 PO 4 / α-Fe 2 O 3 Photocatalytic Properties of Composites

[0051] 1. Photocatalysis experiment

[0052] Weigh 50mg of Ag 3 PO 4 / α-Fe 2 O 3 The sample was ultrasonically dispersed in 100 mL of Rhodamine B solution with a concentration of 5 mg / L. Then, the above mixture was placed in a dark room to magnetically stir for 30 minutes, so that the catalyst and the dye reached the equilibrium of adsorption and desorption. The photocatalytic performance was tested by using a xenon lamp as a light source to simulate sunlight. After centrifuging 4 mL of the solution every 5 minutes, UV-Vis spectroscopy was used. The absorbance was measured by a photometer.

[0053] 2. Photocatalytic performance analysis

[0054] by Ag under visible light 3 PO 4 , α-Fe 2 O 3 and Ag 3 PO 4 / α-Fe 2 O 3 The catalytic degradation efficiency of the composite photocatalyst for Rhodamine B, and the photocatalytic activity of the catalyst was investigated. Depend on Image 6 (a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com