A kind of blank forging molding process of flange type universal joint sliding sleeve for vehicle

A flanged and forging molding technology, applied in the field of forging, can solve the problems of material waste, increase the workload of the staff, and low manufacturing efficiency of the flanged universal joint sliding sleeve, so as to reduce waste, accelerate semi-self-shedding, The effect of accelerated cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

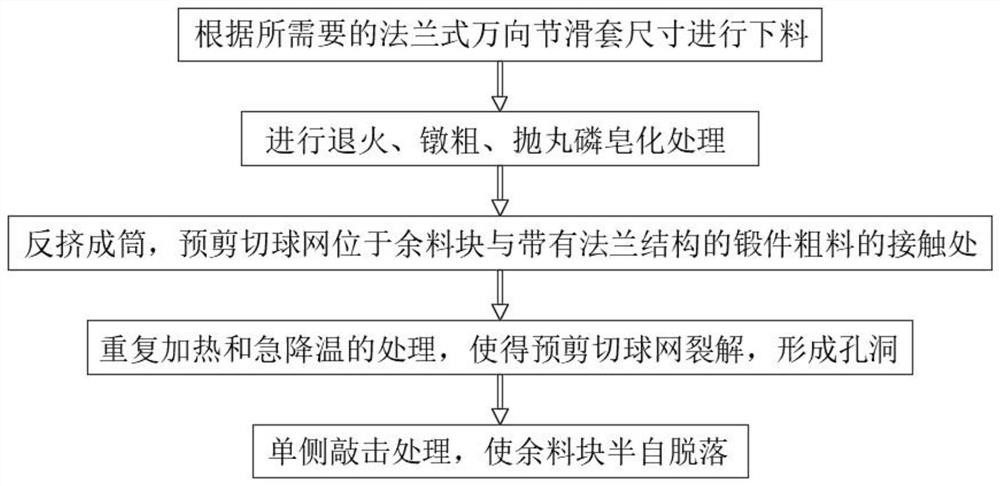

[0047] see figure 1 , a kind of blank forging molding process of flange type universal joint sliding sleeve for vehicles, comprising the following steps:

[0048] S1. Cutting according to the size of the flanged universal joint sliding sleeve required to obtain rough forgings;

[0049] S2. Anneal the rough forgings first, then upsetting, and then perform shot blasting phosphorus saponification, so that the rough forgings have a flange structure;

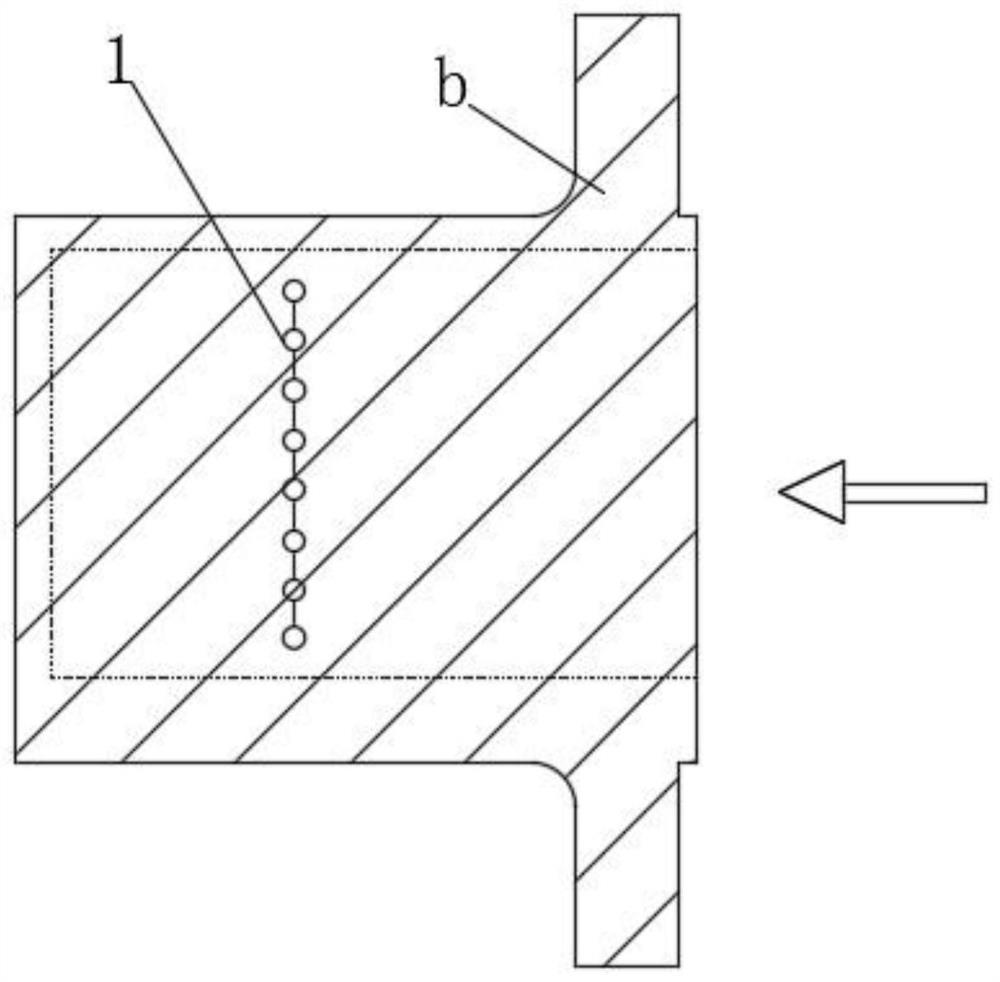

[0050] S3, see image 3 , b in the figure represents the forging rough material with flange structure, and the forging rough material with flange structure is back-extruded into a cylinder, so that the extrusion area in the center of the forging rough material with flange structure is reversely extruded At the same time, the pre-sheared ball net 1 inside will move outward, and finally be located near the contact point between the residual material block and the forging coarse material with flange structure;

[0051] S4. Heating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com