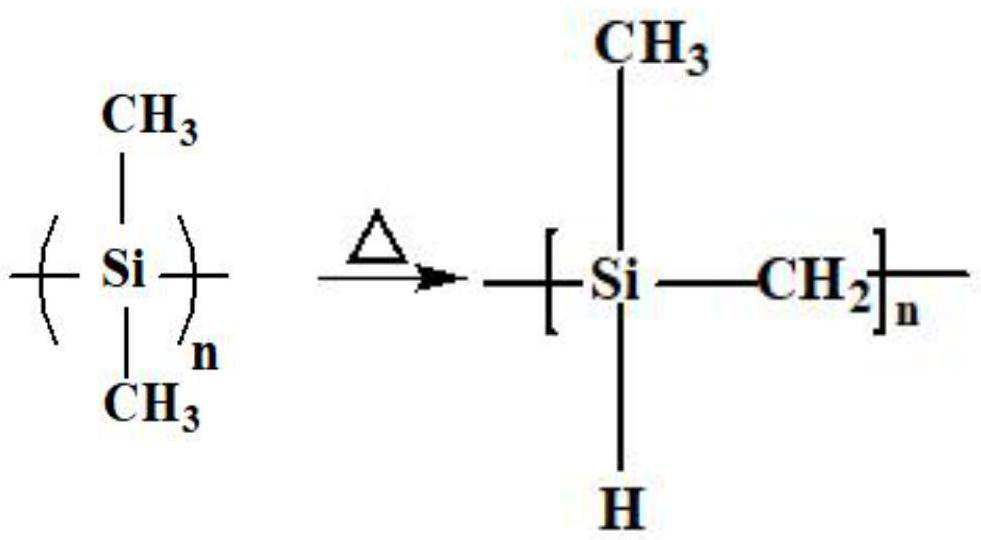

Method for preparing solid polycarbosilane by recycling polydimethylsilane cracking residues

A technology of polydimethylsilane and polycarbosilane is applied in the field of recovering polydimethylsilane cracking residue to prepare solid polycarbosilane, which can solve the problems of difficult separation, increase environmental pressure, increase PCS production and operation cost, etc. Environmental pressure, avoid environmental pollution, improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Put 100Kg polydimethylsilane cracking residue and 100Kg xylene into the mixing tank, stir for 24 hours, and obtain PCS solution (A) containing insoluble matter;

[0023] (2) Put 10Kg diatomite with a particle size of 10 μm and 10Kg xylene into a diatomite mixing tank, stir for 2 hours, and then use a material pump to inject the suspension of diatomite and xylene into a diatomite filter In, until a stable diatomite filter cake (B) is formed;

[0024] (3) Pour the PCS solution (A) containing insoluble matter into a diatomite filter through a material pump, and filter through a diatomite filter cake (B) to obtain a PCS solution (C);

[0025] (4) Transfer the PCS solution (C) to the synthesis kettle, first vacuumize the synthesis kettle to -0.09MPa, then feed nitrogen to normal pressure; open the stirring device and heating device of the synthesis kettle, when the temperature in the synthesis kettle is controlled At 200°C, keep it warm for 4 hours; continue to feed nit...

Embodiment 2

[0029] (1) Put 100Kg polydimethylsilane cracking residue and 100Kg xylene into the mixing tank, stir for 24 hours, and obtain PCS solution (A) containing insoluble matter;

[0030] (2) Put 10Kg diatomite with a particle size of 10 μm and 10Kg xylene into a diatomite mixing tank, stir for 2 hours, and then use a material pump to inject the suspension of diatomite and xylene into a diatomite filter In, until a stable diatomite filter cake (B) is formed;

[0031] (3) Pour the PCS solution (A) containing insoluble matter into a diatomite filter through a material pump, and filter through a diatomite filter cake (B) to obtain a PCS solution (C);

[0032](4) Transfer the PCS solution (C) to the synthesis kettle, first vacuumize the synthesis kettle to -0.09MPa, then feed nitrogen to normal pressure; open the stirring device and heating device of the synthesis kettle, when the temperature in the synthesis kettle is controlled At 200°C, keep it warm for 4 hours; continue to feed nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com