Full-biodegradable modified plastic for plastic-absorbing thin-walled product and preparation method thereof

A thin-walled product and all-biological technology, applied in the field of plastic materials, can solve the problems of low thermal deformation temperature and brittleness of PLA materials, and achieve the effects of simplified process flow, high thermal deformation temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

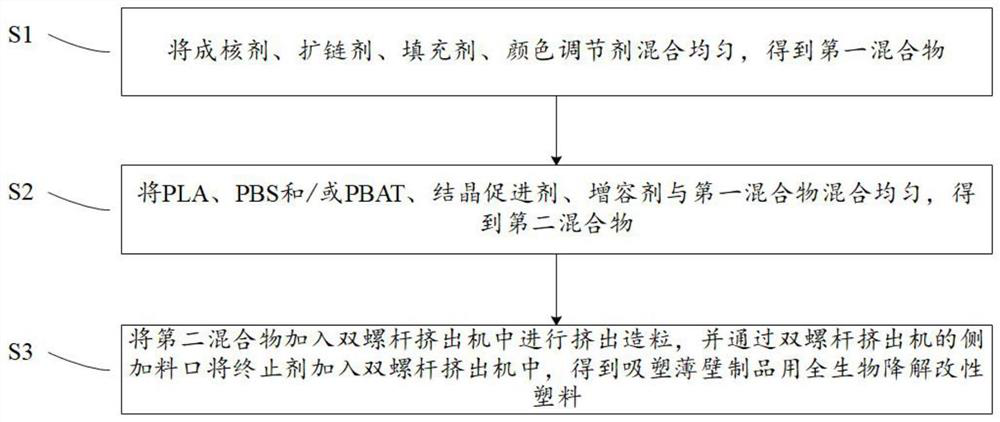

[0022] see figure 1 , the second aspect of the present invention provides a preparation method of a fully biodegradable modified plastic for blister thin-walled products, comprising the following steps:

[0023] S1: Mix the nucleating agent, chain extender, filler, and color modifier uniformly to obtain a first mixture. In this step, the materials are uniformly mixed in a low-speed mixer, and the speed of the low-speed mixer is 40-60 r / min, the mixing time is 5-10 min, and the mixing temperature is normal temperature (about 20-40° C.).

[0024] S2: Mix PLA, PBS and / or PBAT, crystallization accelerator, and compatibilizer with the above-mentioned first mixture uniformly to obtain a second mixture; in this step, the materials are uniformly mixed in a high-speed mixer, and the high-speed mixer The rotating speed is 300~600r / min, the mixing time is 4~8min, and the mixing temperature is 30~50℃.

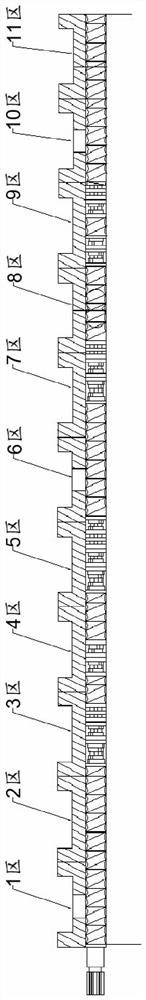

[0025] S3: add the second mixture into the twin-screw extruder for extrusion granula...

Embodiment 1

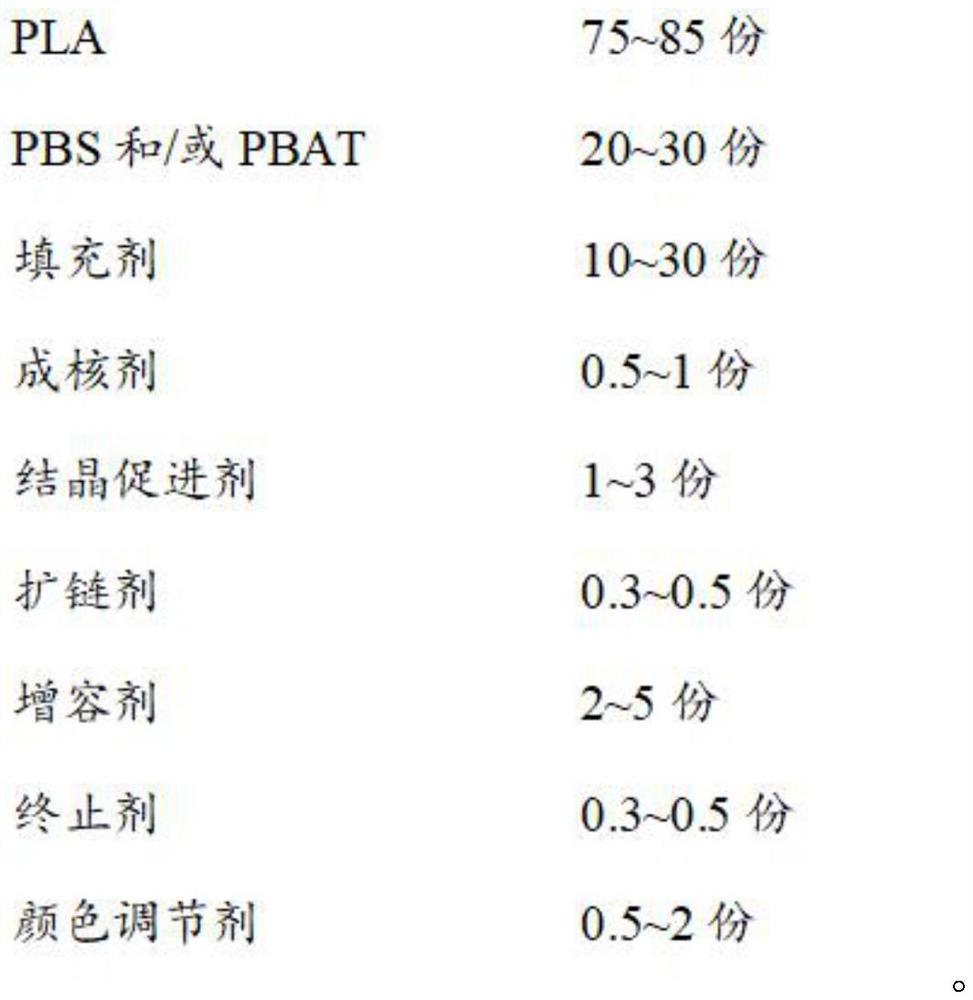

[0031] This embodiment provides a fully biodegradable modified plastic for blister thin-walled products, in parts by weight, including the following components:

[0032]

[0033]

[0034] Specifically, the PLA used is NatureWorks 4032D, the filler is talcum powder, the mesh number is 3000 meshes, the nucleating agent is TMP-6, the crystallization accelerator is glycerol, the chain extender is HDI, and the compatibilizer is maleic anhydride Grafting PLA, the terminator is maleic anhydride, and the color modifier is titanium dioxide.

[0035] The preparation method of the fully biodegradable modified plastic for the blister thin-walled product comprises the following steps:

[0036] Weigh the nucleating agent, the chain extender, the filler, and the color modifier according to the above-mentioned proportions, and mix them uniformly in a low-speed mixer to obtain the first mixture. In this step, the speed of the low-speed mixer is 50 r / min, the mixing time is 8 min, and th...

Embodiment 2

[0041] This embodiment provides a fully biodegradable modified plastic for blister thin-walled products, in parts by weight, including the following components:

[0042]

[0043] Specifically, the PLA used is NatureWorks 2500HP, the filler is talcum powder, and its mesh number is 2000 meshes, the nucleating agent is organic bentonite (particle size 1 μm), the crystallization accelerator is sorbitol, and the chain extender is organic peroxides BPO, the compatibilizer is maleic anhydride grafted PBAT, the terminator is dodecyl mercaptan, and the color regulator is brightener RQT.

[0044] The preparation method of the fully biodegradable modified plastic for the blister thin-walled product comprises the following steps:

[0045] Weigh the nucleating agent, the chain extender, the filler, and the color modifier according to the above-mentioned proportions, and mix them uniformly in a low-speed mixer to obtain the first mixture. In this step, the speed of the low-speed mixer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com