Heat-preservation, sound-insulation and waterproof power generation glass and preparation method thereof

A technology of thermal insulation and sound insulation and glass, which is applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of high thermal conductivity, poor sound insulation, and poor water resistance, and achieve good sound insulation effect, reduce heat energy absorption, and increase light transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

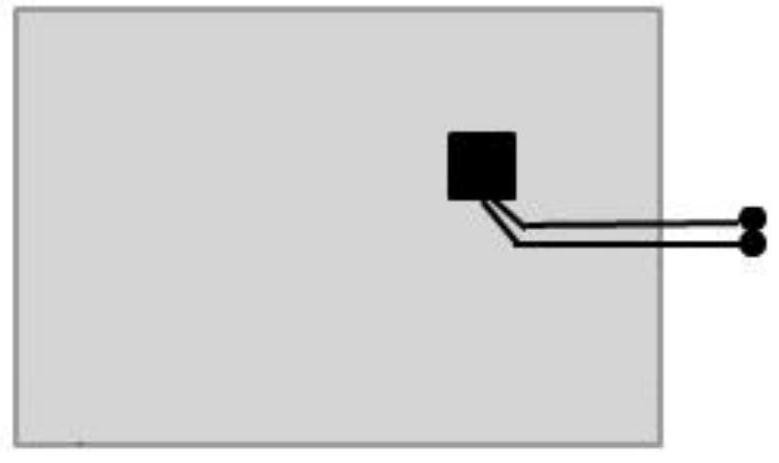

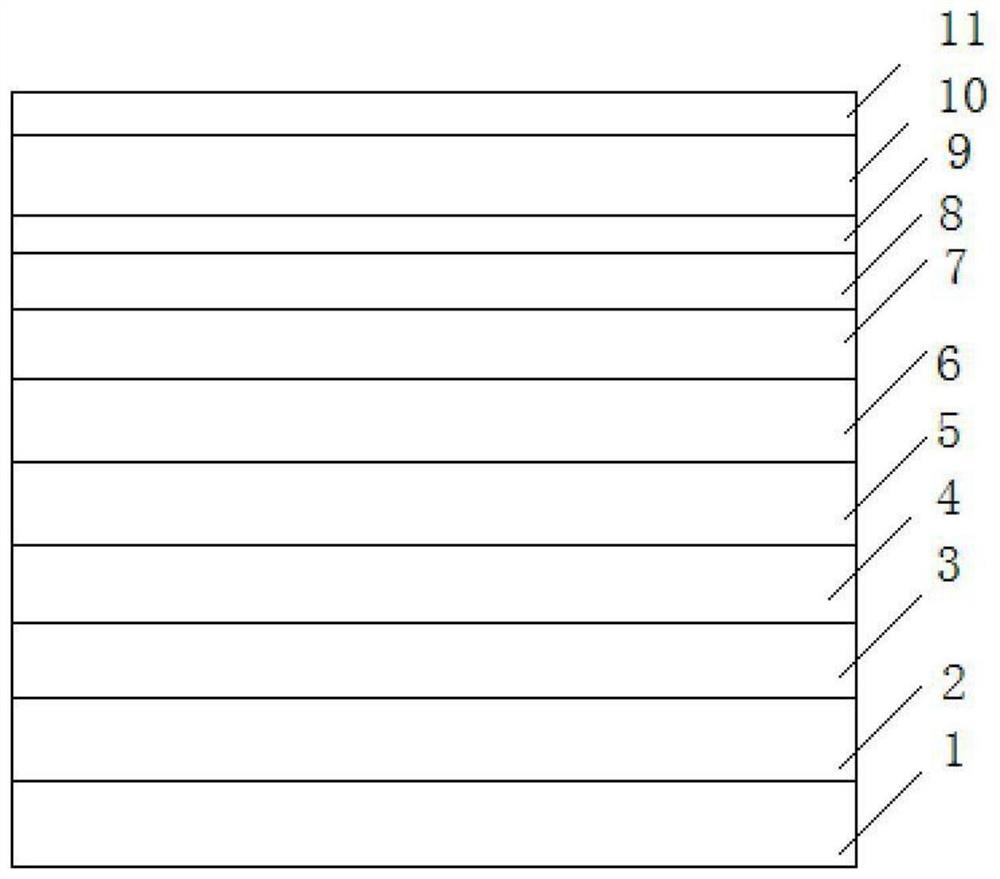

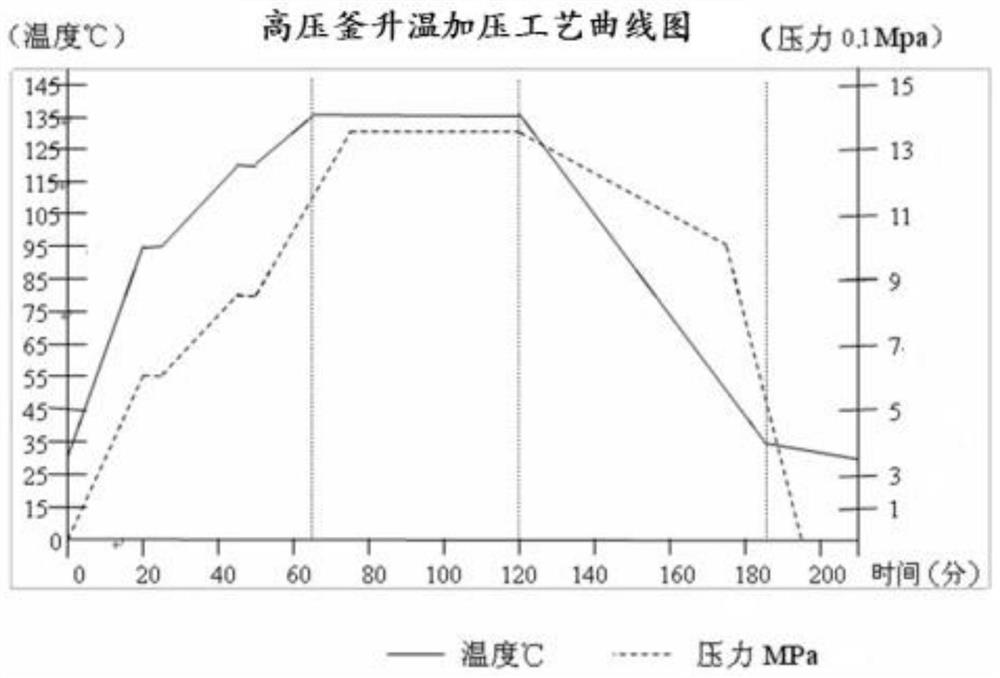

[0055] A power generation glass for heat preservation, sound insulation and waterproof, which comprises from bottom to top: power generation layer, module adhesive film, module back glass, hollow layer, heat reflection film, and outer glass; the hollow layer includes sequentially arranged from inside to outside Hollow structure, hollow polyvinyl chloride frame, the hollow cavity in the hollow polyvinyl chloride frame is filled with desiccant, at least one capillary is arranged in the hollow polyvinyl chloride frame, and one end of each capillary extends into the Hollow structure, the other end extends into the hollow cavity in the hollow polyvinyl chloride frame; the four sides of the component are provided with edge sealant layers; the hollow structure is provided with a junction box; the hollow polyvinyl chloride frame There are through holes on the top, and the inlet and outlet wires of the junction box pass through the through holes; the inlet and outlet wires of the juncti...

Embodiment 2

[0082]The difference between this embodiment and embodiment 1 is that: the transparent conductive film is an ITO transparent conductive film; the material of the back electrode layer is nickel.

Embodiment 3

[0084] The difference between this embodiment and Embodiment 1 is that the transparent conductive film is an AZO transparent conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com