cu 3 pt copper mesh-lithium metal electrode and its preparation method and lithium battery preparation method

A lithium metal electrode and lithium metal technology, applied in the direction of electrolyte battery manufacturing, electrode manufacturing, electrode rolling/calendering, etc., can solve the problems of not being suitable for large-scale production, time-consuming, complicated introduction methods, etc., to reduce the local current density , large surface area, and the effect of reducing the nucleation overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

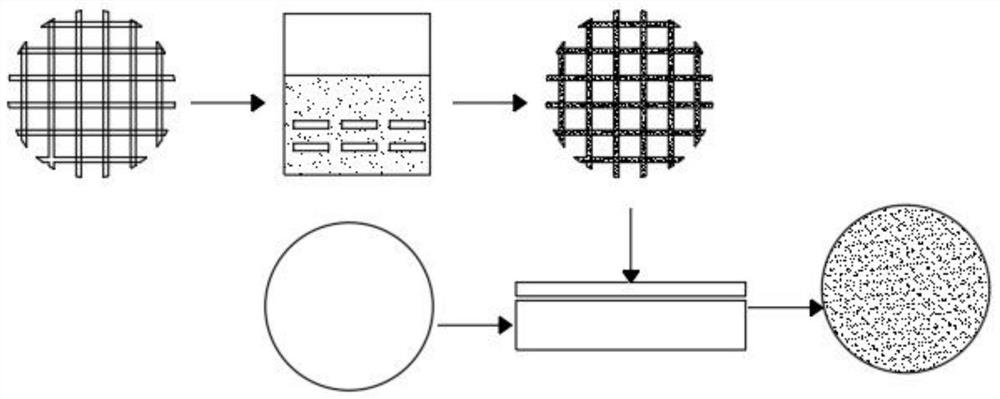

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

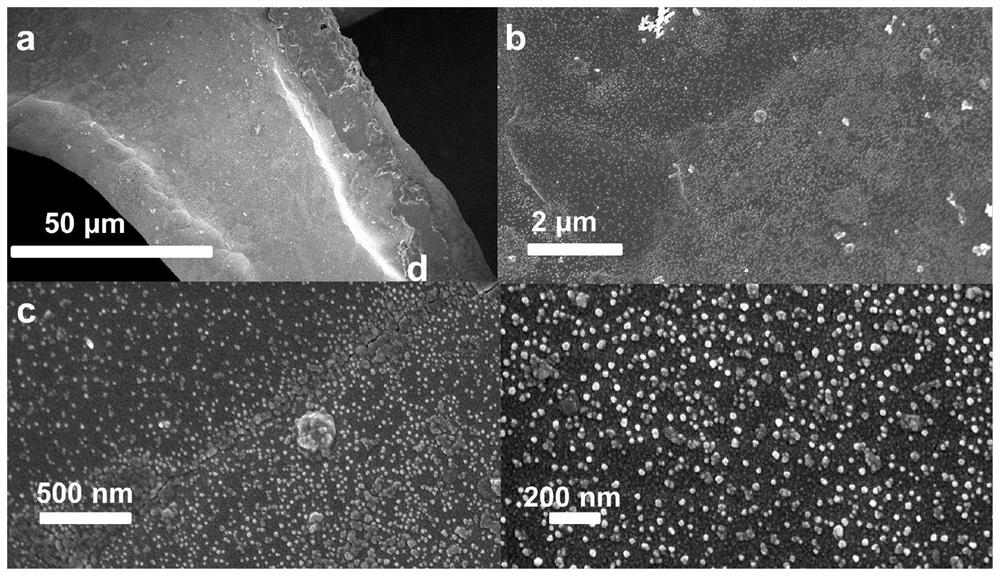

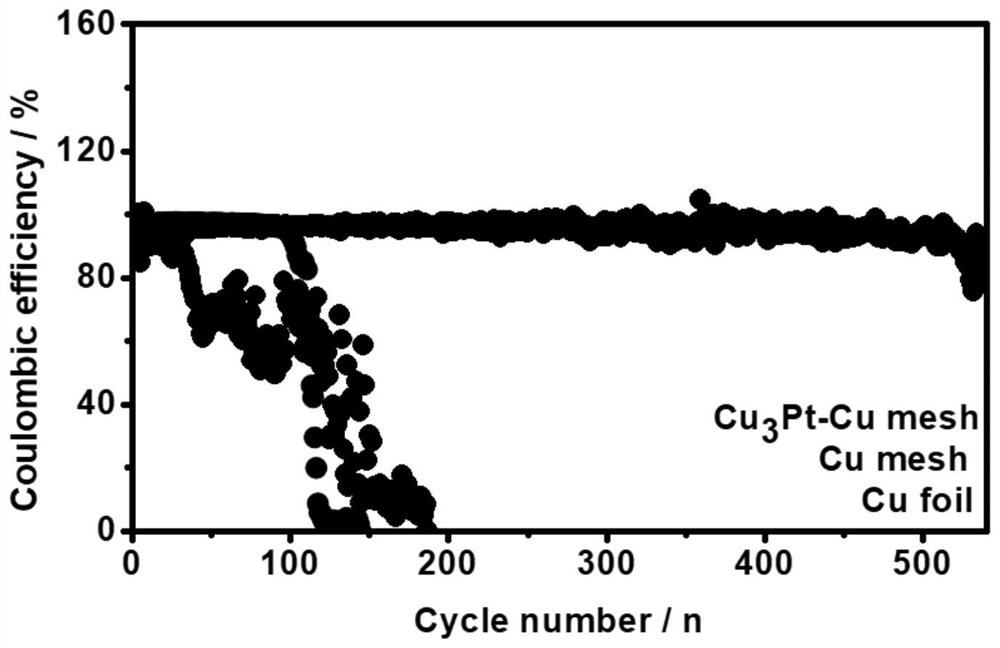

[0030] Cu 3 Pt copper mesh-lithium metal electrode, the electrode is a three-dimensional porous frame structure, the relatively large surface area of the three-dimensional porous frame can reduce the local current density, and many protrusions on the frame can be used as charge centers and nucleation points; it can provide a more uniform The electric field distribution of Li can regulate the electrochemical electroplating and stripping behavior of lithium on the current collector; meanwhile, the porous structure provides a regulating effect for lithium deposition, relieves the volume expansion / contraction caused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com