Residual film recycling machine with edge film recycling device

A film recycling and recycling machine technology, applied in the direction of collectors, agricultural machinery and implements, shovels, etc., can solve the problem of ineffective recycling of edge films, and achieve the effect of simple structure, easy manufacturing, and improved recycling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] In the present invention, for ease of description, the description of the relative positional relationship of each component is described according to the direction in which the observer is located in the cab of the tractor and faces the advancing direction of the present invention as a reference, such as: front, rear, up, down, The positional relationship of left, right, etc. is determined according to the layout direction of the drawings in the specification.

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

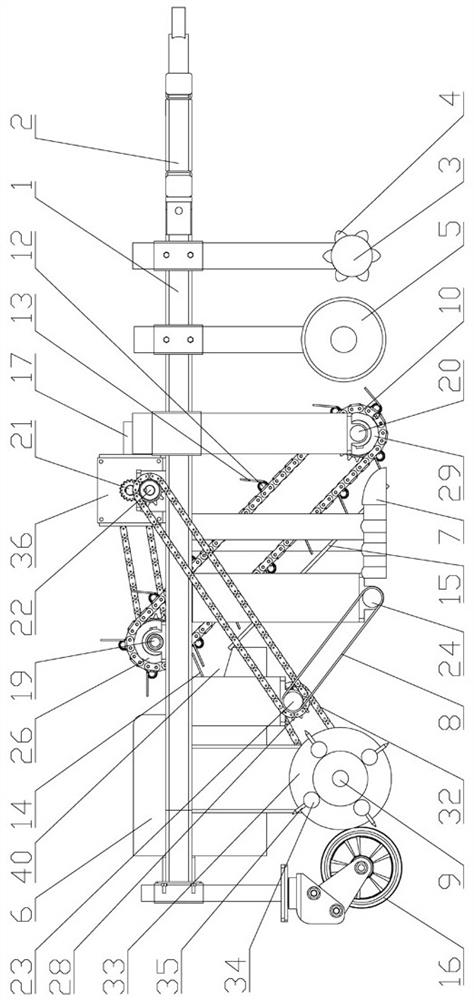

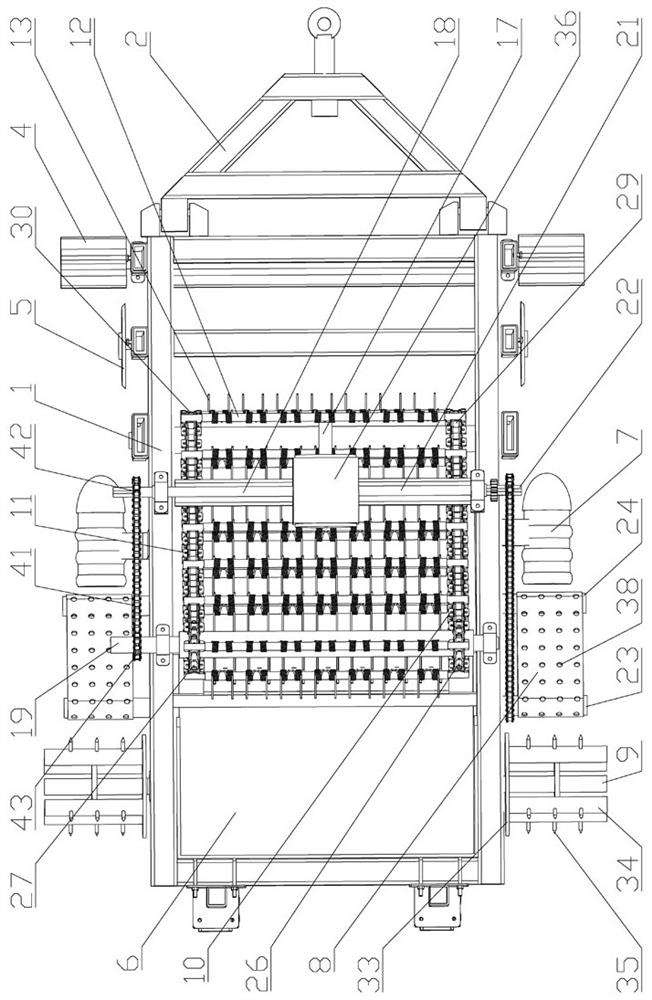

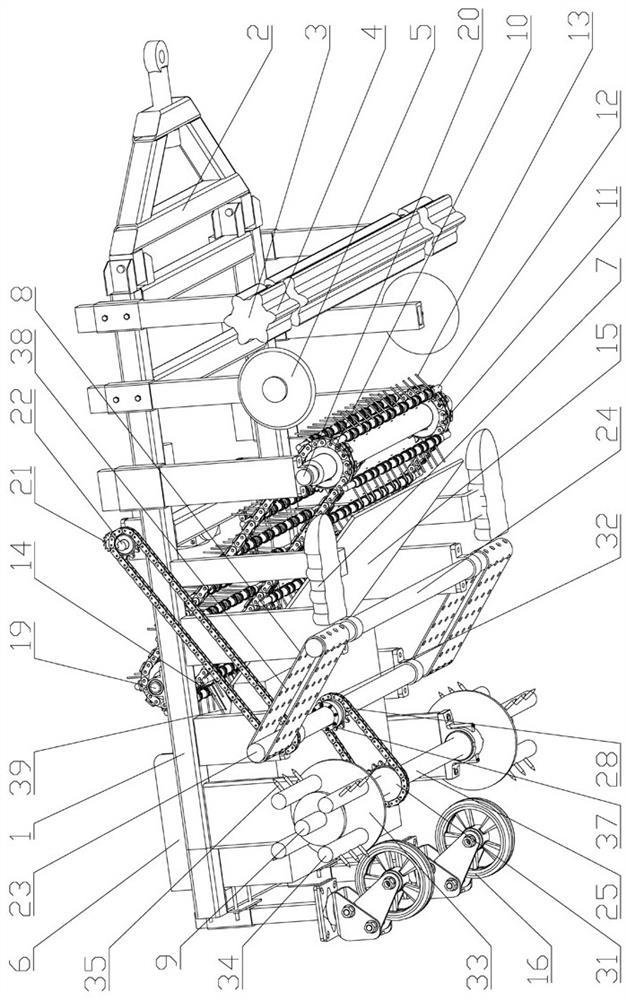

[0020] as attached figure 1 , 2 , 3, and 4, the residual film recovery machine with edge film recovery device includes a frame 1, a film cutting disc 5, a film box 6, a gearbox 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com