Preparation method of nano-silver with stable particle size

A nano-silver, particle size technology, applied in nanotechnology, energy and wastewater treatment, etc., can solve the problems affecting the yield and purification efficiency of nano-silver, and achieve significant low-cost advantages and industrial promotion prospects, controllable process, and reaction process. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of nano-silver with stable particle size, the specific operation steps are:

[0029] Step 1: Put 10mL of 0.2mol / L sodium citrate solution, 15mL of 0.1mol / L polyethylene glycol solution, 5mL of 0.05mol / L sodium tripolyphosphate solution and 40mL of 0.05mol / L sodium hydroxide solution into Mix in a three-necked flask, adopt the hydrothermal reaction method, and stir in a constant temperature water bath at 100°C for 5 minutes;

[0030] Step 2: Add 20 mL of 0.01 mol / L silver nitrate solution dropwise, and continue stirring in a constant temperature water bath at 100°C for 30 minutes after the dropwise addition to obtain a mother solution containing nano-silver;

[0031] Step 3: The mother liquor is washed with water several times and centrifuged at 8000 r / min for 20 minutes to obtain pure nano-silver with an average particle size of 19.6 nm.

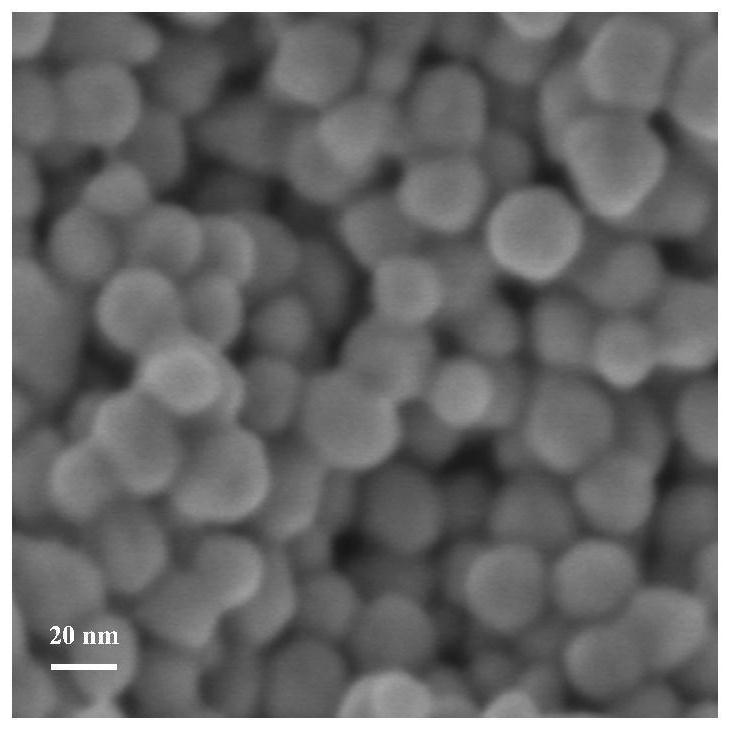

[0032] The nano-silver SEM picture that present embodiment 1 prepares is as follows figure 1 As shown, the XR...

Embodiment 2

[0034] Step 1: 12.5 mL of 0.25 mol / L sodium citrate solution, 10 mL of 0.15 mol / L polyethylene glycol solution, 5 mL of 0.05 mol / L sodium tripolyphosphate solution and 40 mL of 0.05 mol / L sodium hydroxide solution Mix in a three-necked flask, adopt hydrothermal reaction method, and stir in a constant temperature water bath at 80°C for 5 minutes;

[0035] Step 2: Add 25 mL of 0.02 mol / L silver nitrate solution dropwise, and continue stirring in a constant temperature water bath at 80°C for 30 minutes after the dropwise addition to obtain a mother solution containing nano-silver;

[0036] Step 3: The mother liquor is washed with water several times and centrifuged at 8000 r / min for 20 minutes to obtain pure nano-silver with an average particle size of 21.2 nm.

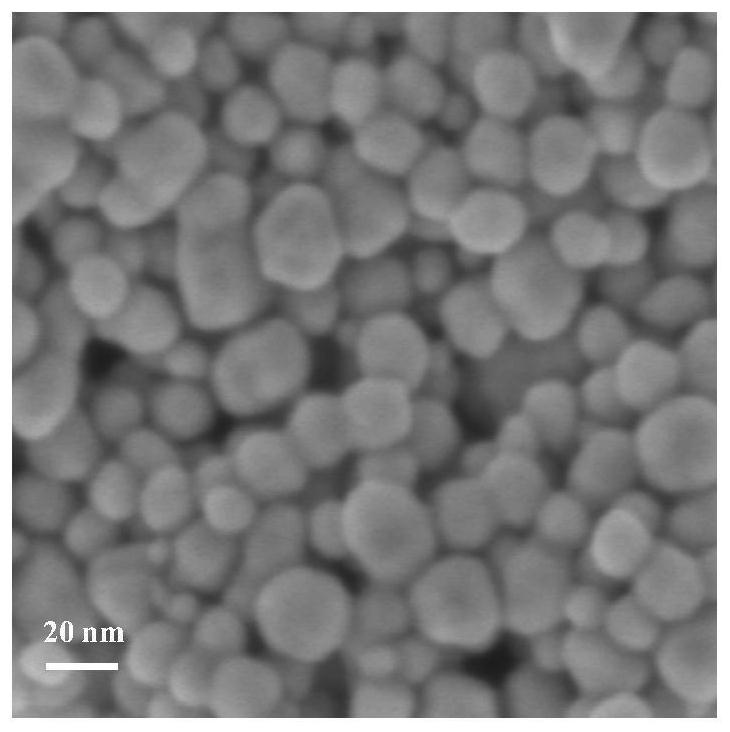

[0037] The nano-silver SEM picture that present embodiment 2 prepares is as follows figure 2 shown.

Embodiment 3

[0039] Step 1: Mix 15 mL of 0.3 mol / L sodium citrate solution, 12.5 mL of 0.2 mol / L polyethylene glycol solution, 6.25 mL of 0.05 mol / L sodium tripolyphosphate solution and 0.1 mol / L sodium hydroxide solution 40mL was placed in a three-necked flask and mixed, using the hydrothermal reaction method, stirring in a constant temperature water bath at 80°C for 5min;

[0040] Step 2: Add 30 mL of 0.03 mol / L silver nitrate solution dropwise, and continue stirring in a constant temperature water bath at 80°C for 30 minutes after the dropwise addition to obtain a mother solution containing nano-silver;

[0041] Step 3: The mother liquor is washed with water several times and centrifuged at 9000 r / min for 15 minutes to obtain pure nano-silver with an average particle size of 18.8 nm.

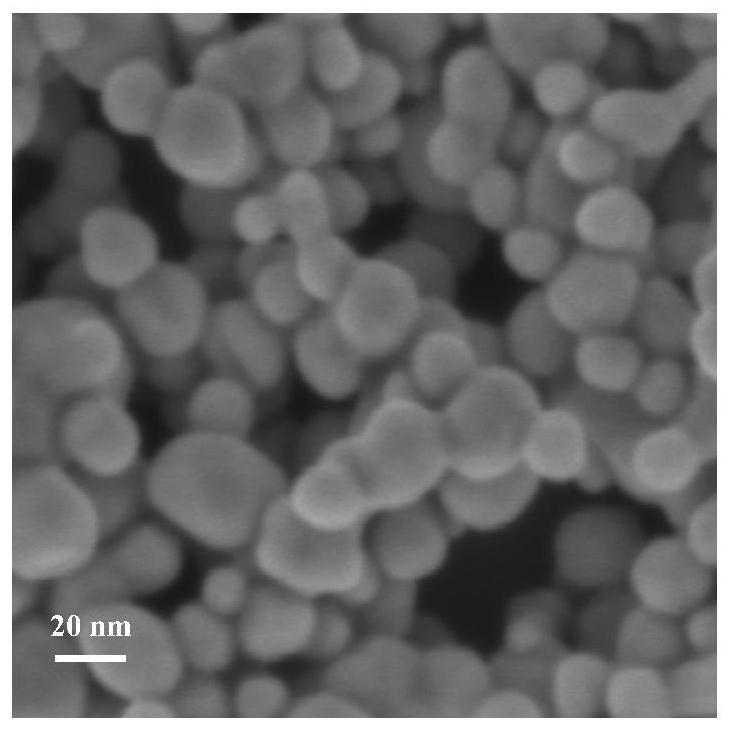

[0042] The nano-silver SEM picture that present embodiment 3 prepares is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com