A kind of preparation method of ethyl 5-methyl-5-hexenoate

A technology of ethyl hexenoate and ethyl acrylate, which is applied in the field of preparation of ethyl 5-methyl-5-hexenoate, can solve the problems of high cost and low yield, achieve low cost, simple operation, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

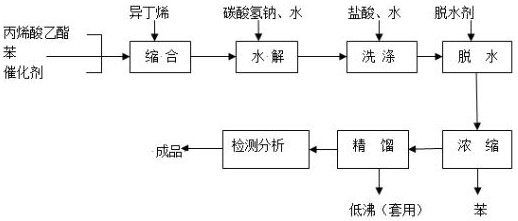

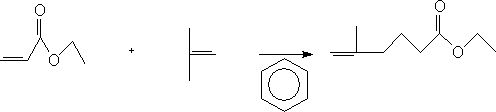

Method used

Image

Examples

Embodiment 1

[0022]In a 500ml clean, dry four-mouth flask, add ethyl acrylate 50g, benzene 200g, with a thermometer, add 4.0g catalyst, catalyst comprising 1.4g aluminum chloride and 2.6g tungsten hexachloride, control temperature 25 °C, through the cylinder gas isobutene 50g, throughisobutene 8h, 25 °C insulation for 24h, and then add (20g sodium bicarbonate and water 100g) of the solution, stirring 0.5h, and then adding (20g 30% hydrochloric acid and water 60g) of the mixture, Stirring 0.5 hours, stationary 0.5 hours, delamination, divided into the lower aqueous layer, washed with 200g of water, layered to obtain the aqueous layer and benzene layer; benzene layer into the barrel, add 1g of dehydrating agent dehydration overnight, dehydrating agent including 0.5g of anhydrous sodium sulfate and 0.5g of n-butanol, concentrated to 50L volume, first atmospheric pressure and then reduced pressure, and then put into the distillation kettle, kettle temperature 95 ° C , top temperature of 75 ° C, ja...

Embodiment 2

[0024] In a 500ml clean, dry four-mouth flask, add ethyl acrylate 50g, benzene 220g, with a thermometer, add 5.0g catalyst, catalyst comprising 1.8g aluminum trichloride and 3.2g tungsten hexachloride, control temperature 28 ° C, through the cylinder gas isobutylene 60g, through about 12h, 28 ° C insulation for 48h, and then add (20g sodium bicarbonate and water 100g) solution, stirring 0.5h, and then adding (20g 30% hydrochloric acid and water 80g) of the mixture, Stir 0.5h, stationary 0.5h, layer, remove the lower aqueous layer, wash with 200g of water to get the aqueous layer and the benzene layer; put the benzene layer into the bucket, add 1g of dehydrating agent to dehydrate overnight, the dehydrating agent comprises 0.6gwt% Anhydrous sodium sulfate and 0.4g n-butanol are concentrated to 55L volume, first atmospheric pressure and then decompression, and then put into the distillation kettle for rectification, the kettle temperature is 100 °C, the top temperature is about 75 °...

Embodiment 3

[0026]In a 500ml clean, dry four-mouth flask, add ethyl acrylate 50g, benzene 250g, with a thermometer, add 6.0g catalyst, catalyst comprising 2.4g aluminum chloride and 3.6g tungsten hexachloride, control temperature 30 °C, through the cylinder gas isobutylene 65g, through about 16h, 30 °C insulation for 60 hours, and then add (20g sodium bicarbonate and water 100g) solution, stirring for 0.5 hours, and then adding (20g 30% hydrochloric acid and water 100g) of the mixture, Stirring 0.5h, stationary 0.5h, layering, divided into the lower aqueous layer, washed with 200g of water, layered to obtain the aqueous layer and benzene layer; benzene layer into the barrel, add dehydrating agent dehydration overnight, dehydrating agent including 0.7g anhydrous sodium sulfate and 0.3g n-butanol, concentrated to 60L volume, first atmospheric pressure and then decompression, and then put into the distillation kettle, kettle temperature 120 ° C, top temperature of about 75 ° C, jacket about 70 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com