Method for removing laser mark of urea-formaldehyde resin button

A urea-formaldehyde resin and button technology, which is used in surface polishing machine tools, machine tools suitable for grinding workpiece edges, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In the preparation method of the post-treatment liquid, the raw material components and proportions used are the same as above, and will not be repeated here.

[0060] In some embodiments of the present invention, the temperature of the post-treatment liquid is 25-40°C. In some embodiments, the temperature of the post-treatment liquid is 40°C or 30°C.

[0061] In some embodiments of the present invention, stirring is performed during the soaking. The present invention has no special limitation on the stirring method, and a stirring method well known to those skilled in the art can be used.

[0062] In some embodiments of the present invention, the soaking time is 5-30 minutes. In some embodiments, the soaking time is 20 minutes.

[0063] In some embodiments of the present invention, the cleaning liquid used in the cleaning is clear water.

[0064] The present invention has no special limitation on the sources of the above-mentioned raw materials, which may be commer...

Embodiment 1

[0067] 1. Put the urea-formaldehyde resin button after laser into the open polishing roller coated with polytetrafluoroethylene coating on the wall of the cylinder, turn the polishing barrel of the open polishing roller, so that the button and the polishing material are fully mixed, and the quality of the button and the polishing material The ratio is 1:2; the polishing material uses polytetrafluoroethylene particles, and the particle size is a regular tetrahedron between 3mm and 5mm; after mixing evenly, add sulfuric acid solution (the concentration of sulfuric acid solution is 95wt%, the sulfuric acid solution The dripping amount is 2wt% of the total mass of the urea-formaldehyde resin button and the polishing material after lasering), after polishing for 40 minutes, take it out and place it in an oven at a baking temperature of 40°C and a baking time of 30 minutes;

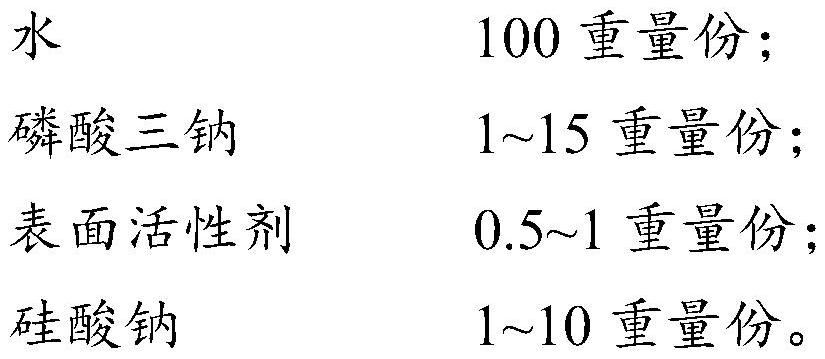

[0068] 2. Configure the post-treatment liquid. The formula of the post-treatment liquid includes:

[0069] ...

Embodiment 2

[0075] 1. Put the urea-formaldehyde resin button after laser into the open polishing roller coated with polytetrafluoroethylene coating on the wall of the cylinder, turn the polishing barrel of the open polishing roller, so that the button and the polishing material are fully mixed, and the quality of the button and the polishing material The ratio is 1:3; the polishing material uses polytetrafluoroethylene particles, and the particle size is a regular tetrahedron between 3mm and 5mm; after mixing evenly, add sulfuric acid solution (the concentration of sulfuric acid solution is 90wt%, the sulfuric acid solution The dripping amount is 1wt% of the total mass of the urea-formaldehyde resin button and the polishing compound after lasering), after polishing for 40 minutes, take it out and place it in an oven at a baking temperature of 40°C and a baking time of 40 minutes;

[0076] 2. Configure the post-treatment liquid. The formula of the post-treatment liquid includes:

[0077] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com