Polysiloxane supramolecular elastomer with high mechanical properties and self-repairing function as well as preparation method and application thereof

A technology for supramolecular elastomers and mechanical properties, applied in the field of supramolecular elastomers and conductive elastomers, can solve problems such as low tensile strength, and achieve the effects of easy molding, strong practicability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

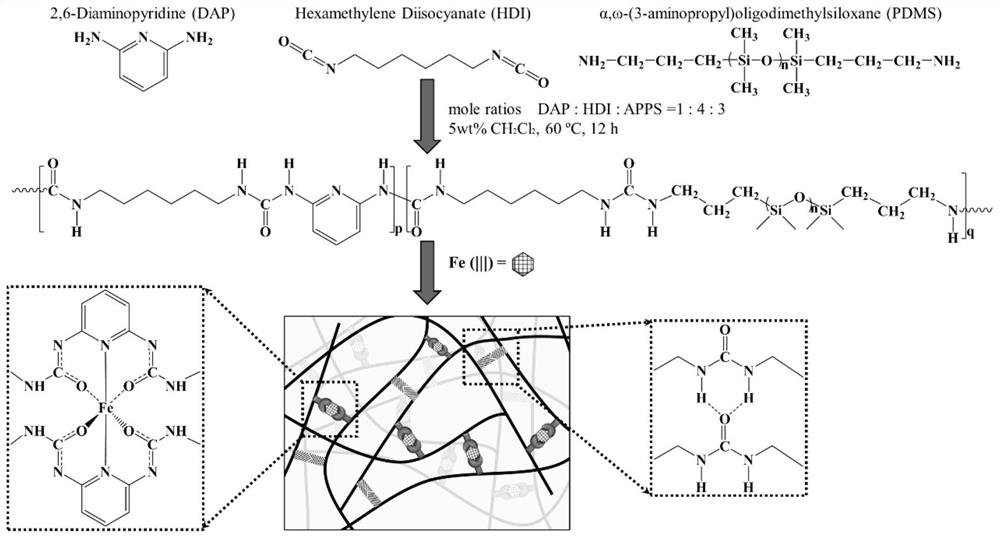

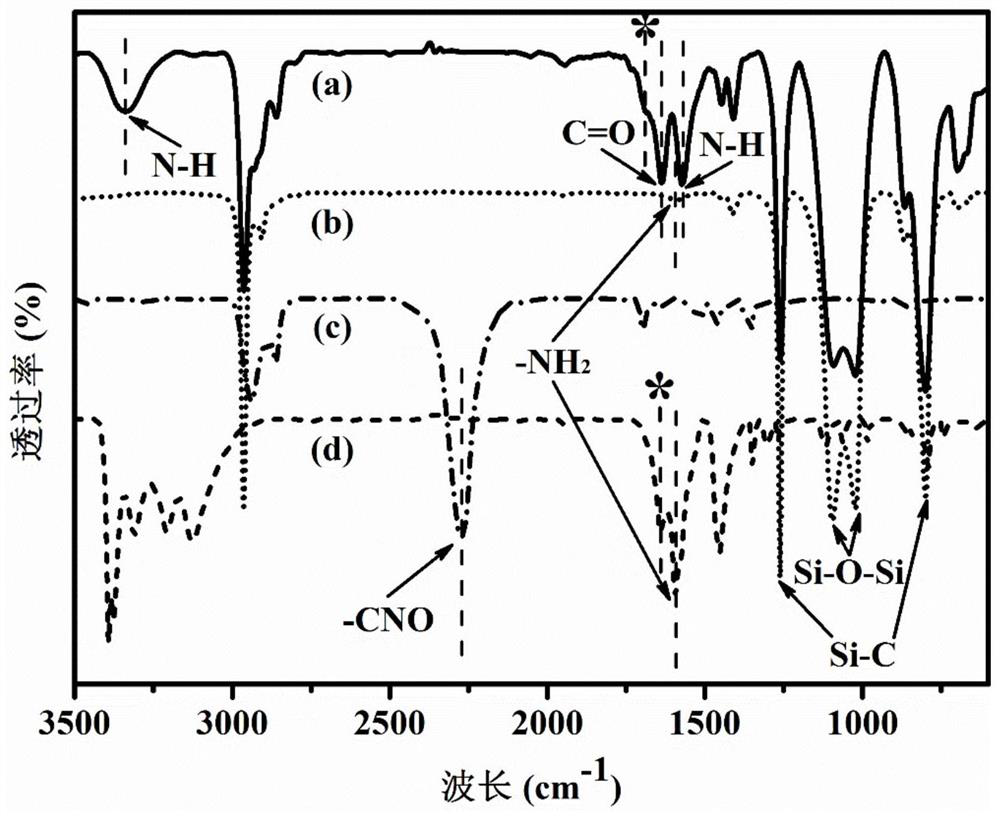

[0041] (1) Add 6.73g of 1,6-hexamethylene diisocyanate (40.00mmol) in dichloromethane solution to the round bottom flask connected with mechanical stirring, reflux condenser and inert protection device, then add 90.00g of bis(3- aminopropyl) terminated polydimethylsiloxane (30.00mmol) in dichloromethane and 1.09g 2,6-diaminopyridine (10.00mmol) in dimethyl sulfoxide; their solid content is 20%. Raise the reaction temperature to 60° C., and react for 12 hours under the protection of nitrogen to obtain a polysiloxane block copolymer containing pyridine ligands. figure 2 Shown is the product polysiloxane block copolymer containing pyridine ligands (a) and starting material 1,6-hexamethylene diisocyanate (c), bis(3-aminopropyl) terminated polydimethylsiloxane (b), IR characterization of 2,6-diaminopyridine (d). It can be seen from the figure that Si-O-Si and Si-C peaks and pyridine ligand peaks are clearly observed in (a) (the position indicated by * in the figure), which show...

Embodiment 2

[0045] Except that 0.90g ferric chloride hexahydrate / dehydrated ethanol solution (3.33mmol) is replaced with 0.54g ferric chloride hexahydrate / dehydrated ethanol solution (2.00mmol) in step 2, all the other are identical with embodiment 1, and product is named after PDMS-HDA@Fe-1 / 5.

Embodiment 3

[0047] Except that 0.90g ferric chloride hexahydrate / dehydrated ethanol solution (3.33mmol) is replaced by 2.70g ferric chloride hexahydrate / dehydrated ethanol solution (10.00mmol) in step 2, all the other are identical with embodiment 1, and product is named after PDMS-HDA@Fe-1 / 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com