Novel copper surface roughness etching stabilizer and preparation method thereof

A stabilizer and roughness technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, printed circuits, etc., can solve copper surface poor oxidation resistance, low roughness uniformity, oxidation blackening, etc. problem, to achieve the effect of improving the uniformity of roughness and inhibiting self-decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

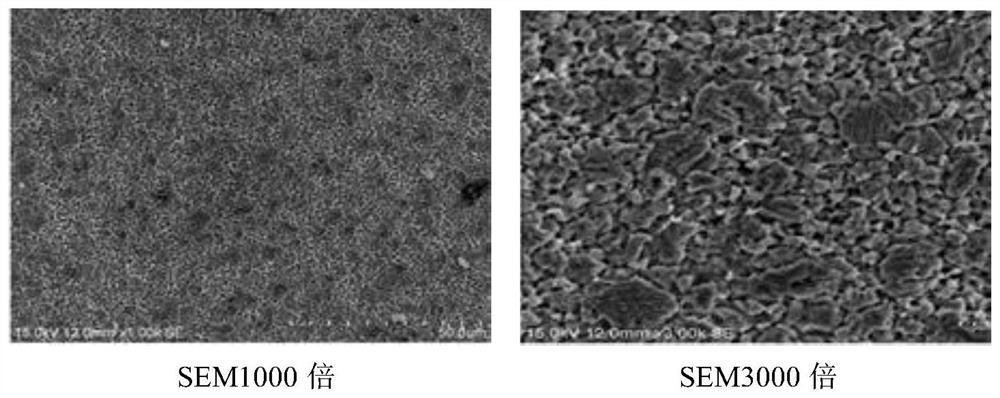

Embodiment 1

[0025] A new copper surface roughness bite stabilizer, comprising the following components by mass fraction, sulfuric acid 8%, hydrogen peroxide 6%, diethylene glycol 1%, cyclohexylamine 2%, 2-methylimidazole 1%, 2% of 5-aminotetrazole, 2% of 5-amino-1-methyltetrazole, 78% of deionized water.

[0026] The preparation method is as follows: S1) weigh each component according to the mass fraction; S2) add deionized water, cyclohexylamine, 2-methylimidazole, 5-aminotetrazole, 5-amino-1- Methyl tetrazole, then slowly add sulfuric acid, stir evenly, add diethylene glycol and hydrogen peroxide, stir evenly to obtain the finished product; the stirring speed is 50-60 times / min.

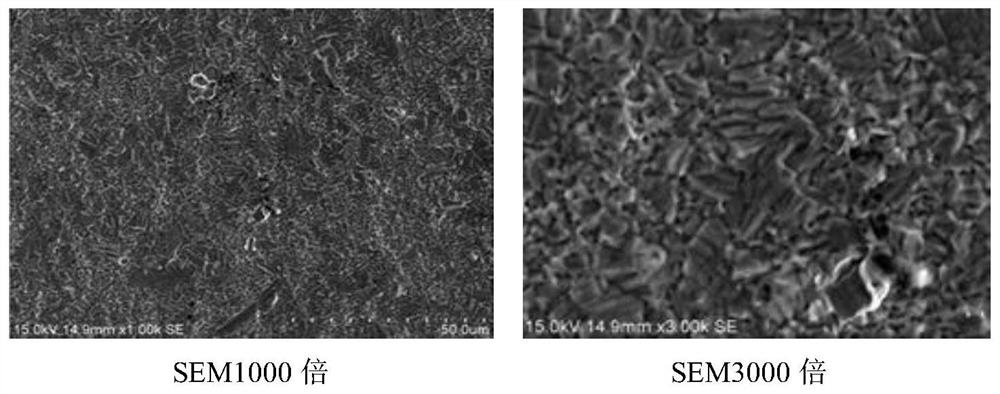

Embodiment 2

[0028] A novel copper surface roughness bite stabilizer, comprising the following components by mass fraction, sulfuric acid 5%, hydrogen peroxide 5%, propylene glycol butyl ether 0.5%, cyclohexylamine 2.5%, 2-methylimidazole 1%, 5% - Aminotetrazole 1%, 5-amino-1-methyltetrazole 1%, deionized water 84%.

[0029] The preparation method is as follows: S1) weigh each component according to the mass fraction; S2) add deionized water, cyclohexylamine, 2-methylimidazole, 5-aminotetrazole, 5-amino-1- Methyl tetrazole, then slowly add sulfuric acid, stir evenly, add propylene glycol butyl ether and hydrogen peroxide, stir evenly to obtain the finished product; the stirring speed is 50-60 times / min.

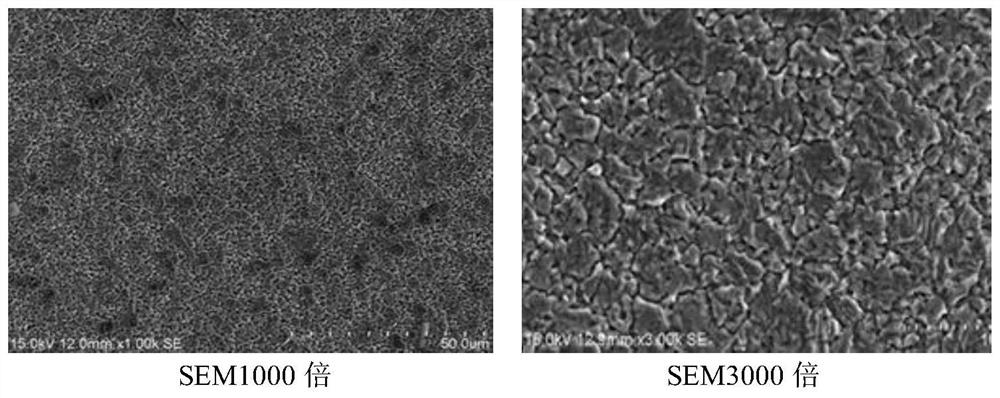

Embodiment 3

[0031] A new copper surface roughness bite stabilizer, comprising the following components by mass fraction, sulfuric acid 7%, hydrogen peroxide 2%, diethylene glycol 1%, diethanolamine 3%, 2-methylimidazole 1%, 5% - Aminotetrazole 1%, 5-amino-1-methyltetrazole 1%, deionized water 84%.

[0032] The preparation method is as follows: S1) weigh each component according to the mass fraction; S2) add deionized water, propylene glycol butyl ether, 2-methylimidazole, 5-aminotetrazole, 5-amino-1- Methyl tetrazole, then slowly add sulfuric acid, stir evenly, add diethylene glycol and hydrogen peroxide, stir evenly to obtain the finished product; the stirring speed is 50-60 times / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com