Biaxially stretched polyester film with stable electrical properties and preparation method thereof

A technology of biaxially oriented polyester and electrical properties, which is applied in the field of biaxially oriented polyester film for electrical engineering and its preparation, can solve the problems of poor post-sequence reworkability and uneven roughness of finished products, and achieves roughness of the film. The effect of improved uniformity, stable performance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

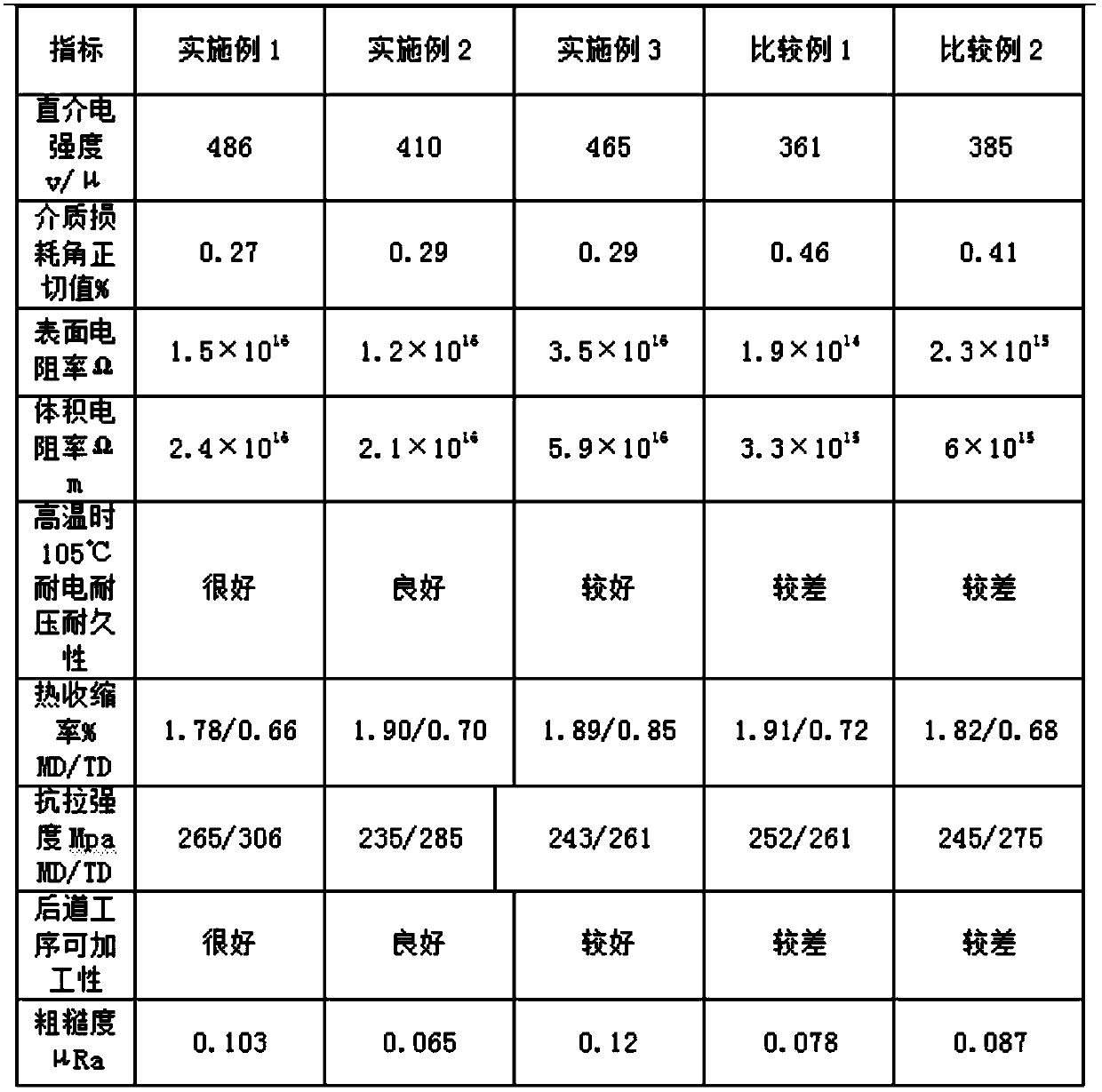

Examples

Embodiment 1

[0023] Embodiment 1: 1), choosing the ultra-bright polyester chip that the viscosity of 30% by weight is more than 0.63 contains magnesium acetate (magnesium acetate content is 180ppm), the high concentration that the viscosity of 20% by weight is more than 0.63 Nanoscale silicon oxide (particle size 2 ~ 3um, the average diameter of silicon oxide particles is about 100nm) polyester chips and 50% by weight of low-concentration silicon oxide polyester chips with a viscosity above 0.63, of which high-concentration nano-scale silicon oxide The silica concentration in the polyester chip was 18000ppm, and the silica concentration in the low-concentration silica polyester chip was 2800ppm.

[0024] 2) Mix the above three kinds of slices, pneumatically transport them to the silo, and then send them to a fluidized bed at 175°C for pre-crystallization, dry them in a drying tower at 170°C for 3-4 hours, and melt them at 280°C when the water content of the slices is less than 40ppm Extrud...

Embodiment 2

[0029] Embodiment 2: 1), choosing the ultra-bright polyester chip that the viscosity of 50% by weight is more than 0.63 contains magnesium acetate (magnesium acetate content is 230ppm), the high concentration that the viscosity of 5% by weight is more than 0.63 Nano-scale silicon oxide (particle size 0.5-1.5um, average diameter of silicon oxide particles is about 125nm) polyester chips and 45% by weight of low-concentration silicon oxide polyester chips with a viscosity above 0.63, in which high-concentration nano-scale The silicon oxide concentration in the silicon polyester chip is 19000ppm, and the silicon oxide concentration in the low-concentration silicon oxide polyester chip is 3000ppm.

[0030] 2) Mix the above three kinds of slices, pneumatically transport them to the silo, and then send them to a fluidized bed at 175°C for pre-crystallization, dry them in a drying tower at 170°C for 3-4 hours, and melt them at 270°C when the water content of the slices is less than 40...

Embodiment 3

[0035] Embodiment 3: 1), choosing the ultra-bright polyester chip that the viscosity of 70% by weight is more than 0.63 contains magnesium acetate (magnesium acetate content is 280ppm), the high concentration that the viscosity of 10% by weight is more than 0.63 Nano-scale silicon oxide (particle size 0.5-1.5um, average diameter of silicon oxide particles is about 150nm) polyester chips and 20% by weight of low-concentration silicon oxide polyester chips with a viscosity above 0.63, in which high-concentration nano-scale The silicon oxide concentration in silicon polyester chips is 20000ppm, and the silicon oxide concentration in low-concentration silicon oxide polyester chips is 3500ppm.

[0036] 2) Mix the above three kinds of slices, pneumatically transport them to the silo, and then send them to a fluidized bed at 175°C for pre-crystallization, dry them in a drying tower at 170°C for 3-4 hours, and melt them at 285°C when the water content of the slices is less than 40ppm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com