Preparation method of radiation-proof, corrosion-resistant and waterproof fabric machine

A corrosion-resistant and radiation-proof technology, applied in the direction of light-resistant fibers, liquid-repellent fibers, fiber treatment, etc., can solve the problems of low production efficiency, large thickness, poor protection effect, etc., to reduce consumption and protect the effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

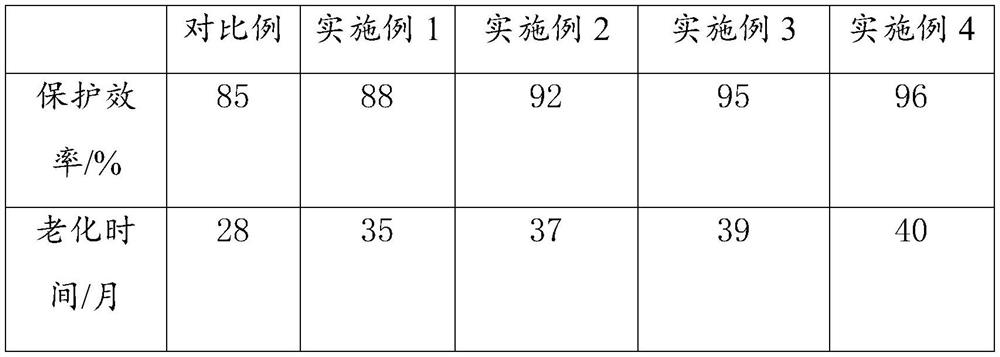

Examples

Embodiment 1

[0026] Step 1: Preparation before the official work of the machine: Use distilled water to clean the working machine, after it is completely cleaned, dry the machine, then fully disinfect the machine, and finally turn on the machine for preheating;

[0027] Step 2: Preparation of relevant raw materials: After collecting all the raw materials participating in the reaction according to the standard, conduct a comprehensive test on the qualification of the raw materials, eliminate unqualified batches of raw materials in time, and put the qualified raw materials into suitable containers after disinfection stand-by;

[0028] Step 3: Production of the waterproof fabric layer: Polyurethane fiber and nylon fiber are used as raw materials for blending to obtain yarn and made into fabric by machine, and then 10 parts of polyethylene paste resin, 20 parts of ultra-fine aluminum hydroxide, propylene When the mixture of 5 parts of alcohol and 20 parts of butyl acrylate is heated to 55 degr...

Embodiment 2

[0034] Step 1: Preparation before the official work of the machine: Use distilled water to clean the working machine, after it is completely cleaned, dry the machine, then fully disinfect the machine, and finally turn on the machine for preheating;

[0035] Step 2: Preparation of relevant raw materials: After collecting all the raw materials participating in the reaction according to the standard, conduct a comprehensive test on the qualification of the raw materials, eliminate unqualified batches of raw materials in time, and put the qualified raw materials into suitable containers after disinfection stand-by;

[0036] Step 3: Production of the waterproof fabric layer: Polyurethane fiber and nylon fiber are used as raw materials for blending to obtain yarn and made into fabric by machine, and then 13 parts of polyethylene paste resin, 30 parts of ultra-fine aluminum hydroxide, propylene When the mixture of 7 parts of alcohol and 23 parts of butyl acrylate is heated to 55 degr...

Embodiment 3

[0042] Step 1: Preparation before the official work of the machine: Use distilled water to clean the working machine, after it is completely cleaned, dry the machine, then fully disinfect the machine, and finally turn on the machine for preheating;

[0043] Step 2: Preparation of relevant raw materials: After collecting all the raw materials participating in the reaction according to the standard, conduct a comprehensive test on the qualification of the raw materials, eliminate unqualified batches of raw materials in time, and put the qualified raw materials into suitable containers after disinfection stand-by;

[0044] Step 3: Fabrication of the waterproof fabric layer: Polyurethane fiber and nylon fiber are used as raw materials for blending to obtain yarn and made into fabric by machine, and then 17 parts of polyethylene paste resin, 40 parts of ultra-fine aluminum hydroxide, propylene When the mixture of 8 parts of alcohol and 28 parts of butyl acrylate is heated to 55 deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com