Carbon felt with pouring sealant, electrode comprising carbon felt and flow battery pile

A liquid flow battery and potting glue technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of reduced battery performance, large contact resistance, complex stack structure, etc., to improve battery performance and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention are further described below with reference to the accompanying drawings.

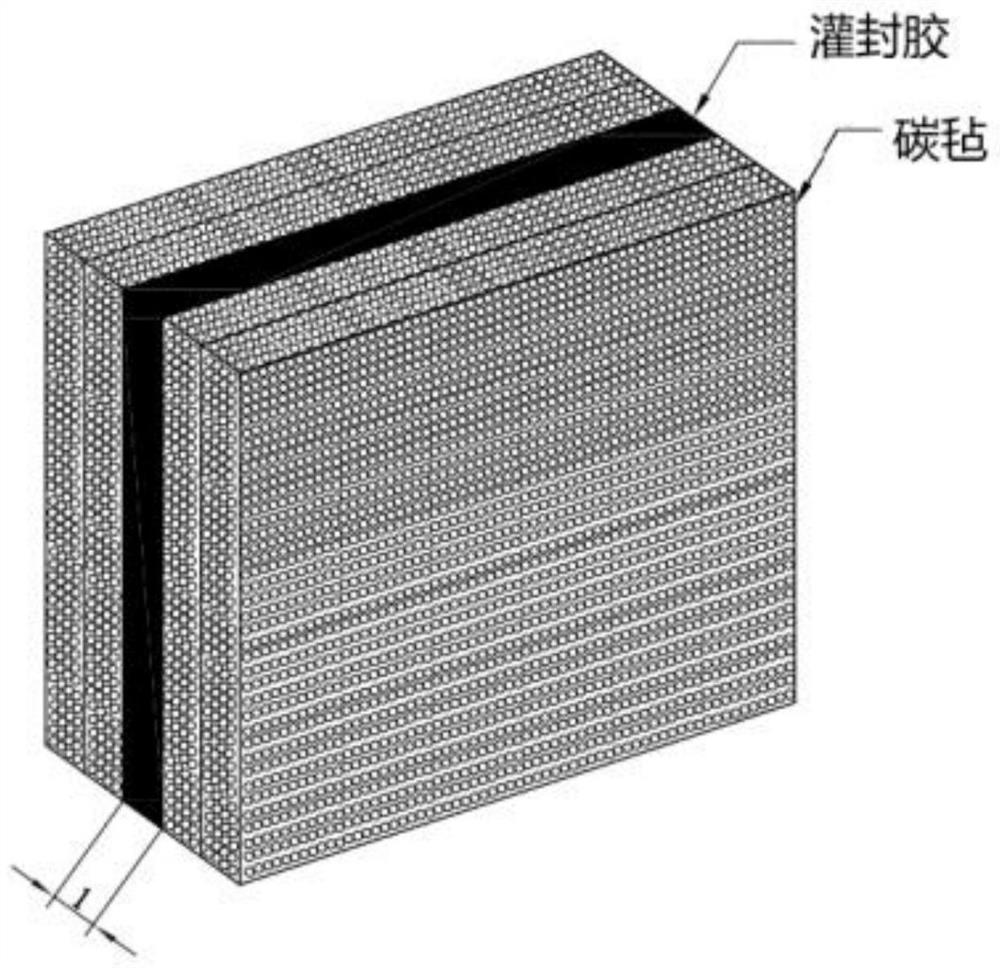

[0032] like figure 1 As shown, a carbon felt with potting glue of the present invention fills the pores in the middle of the carbon felt with the potting glue, and divides the carbon felt into positive and negative electrodes. The carbon felt can pass current but cannot pass through electrolysis. liquid.

[0033] A preparation method of carbon felt with potting glue, comprising the following steps:

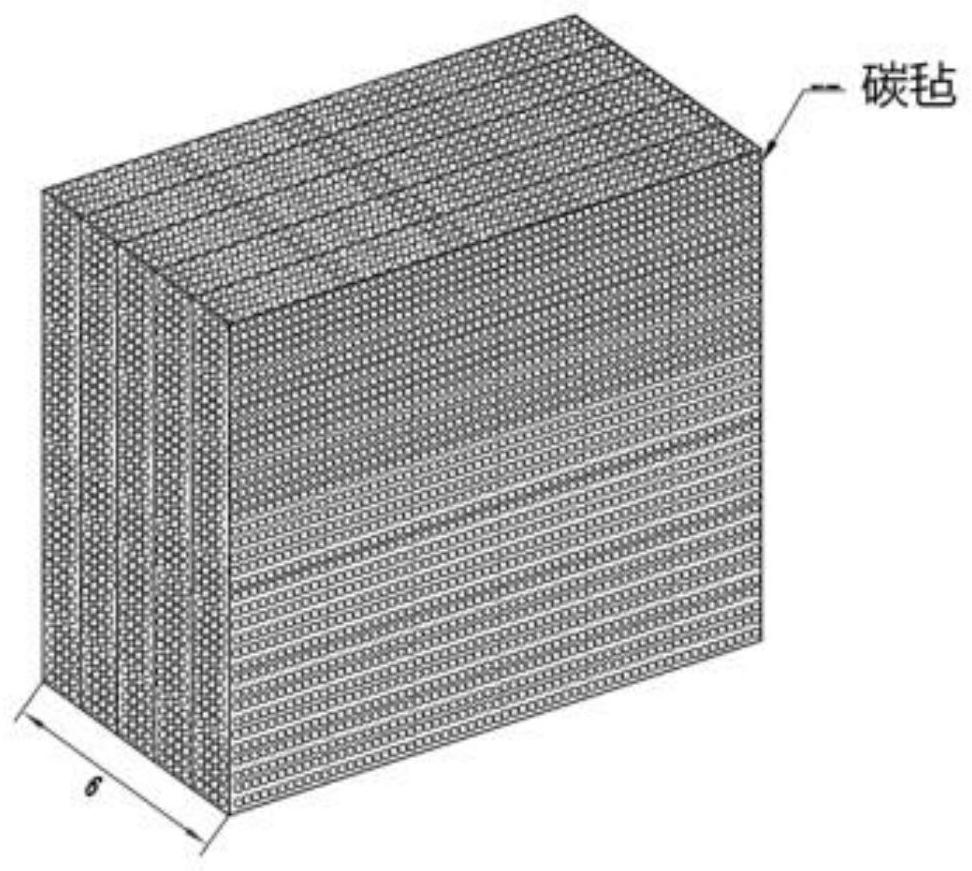

[0034] S1. Prepare carbon felt materials, such as figure 2 shown;

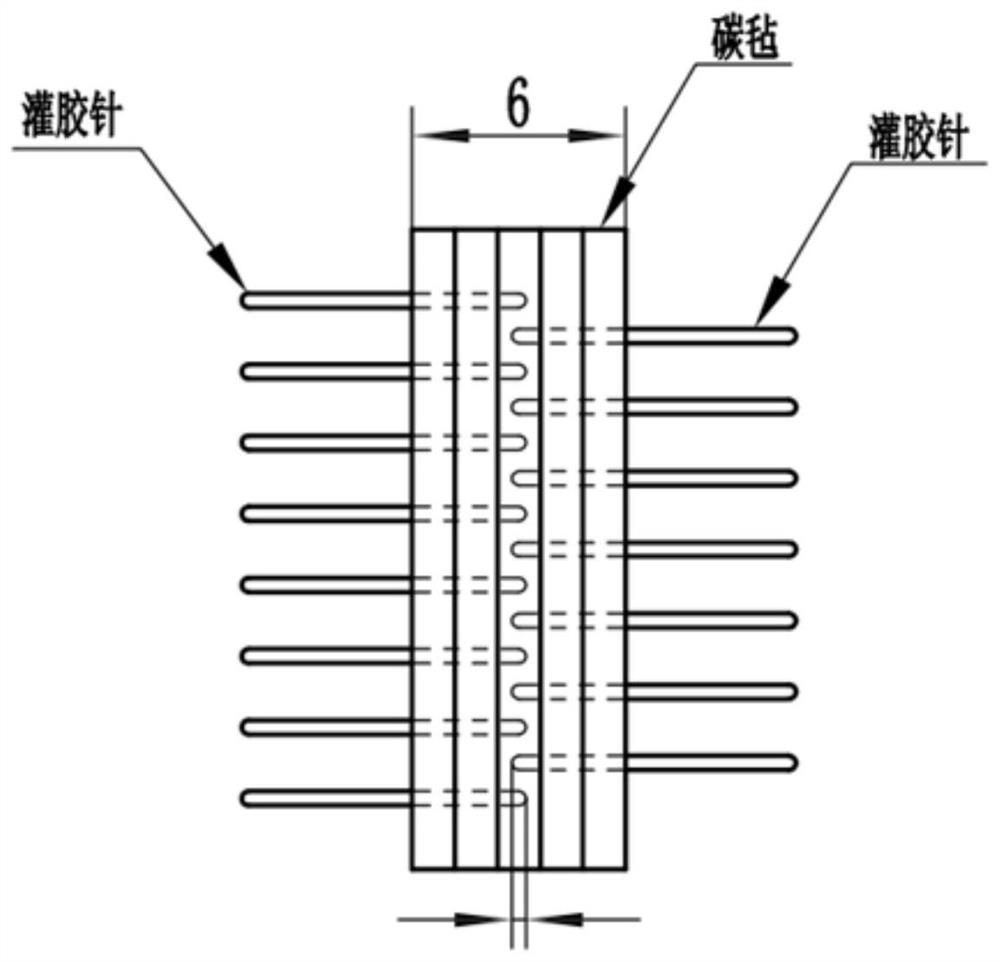

[0035] S2. Insert the glue filling needle into the carbon felt evenly from the two sides of the carbon felt. One end of the glue filling needle is leaked on the outer surface of the carbon felt, and the other end of the glue filling needle is located inside the carbon felt. For example image 3 and Figure 4 The glue filling needles on the left and right sides are asymmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com