Brake pump direct-drive permanent magnet motor

A permanent magnet motor and motor technology, which is applied to synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., can solve the problems of large motor size, improve performance and reduce production costs. , The effect of reducing the difficulty of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

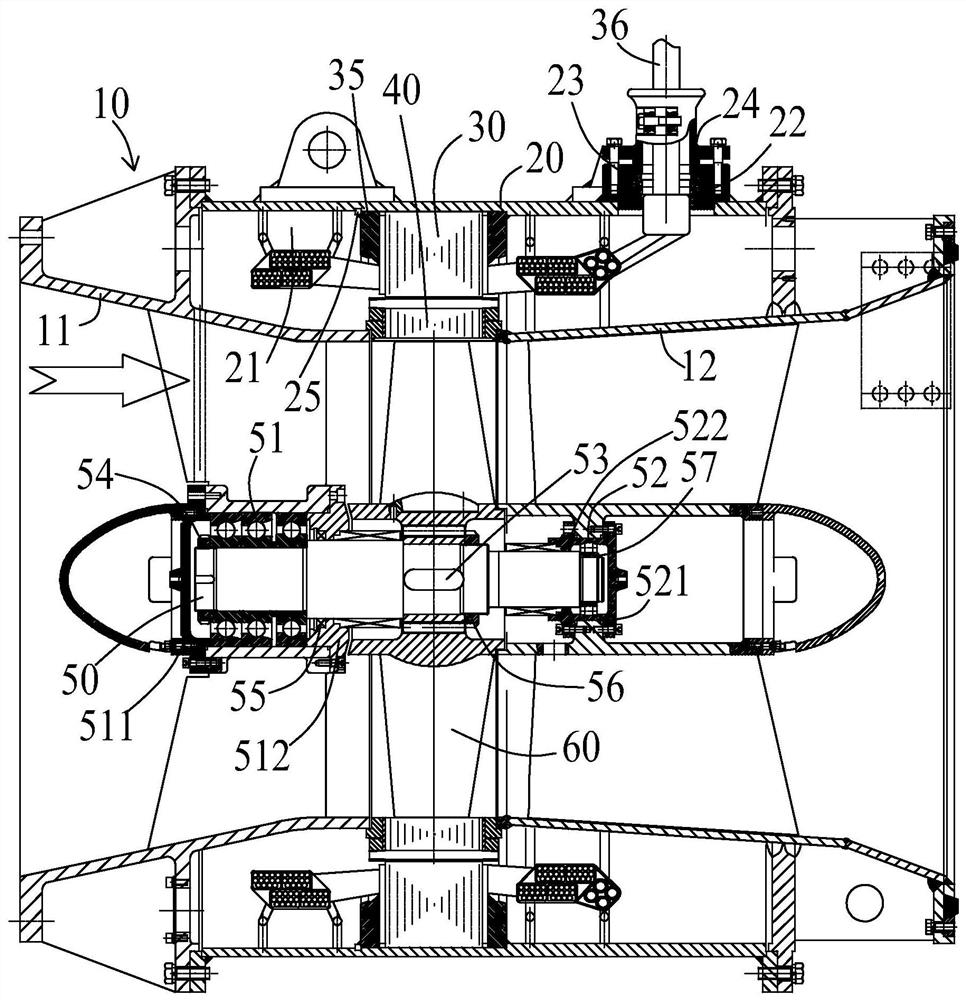

[0021] refer to figure 1 , the pump gate direct drive permanent magnet motor of the present invention includes a connection base 10, a casing 20, a stator assembly 30, a rotor assembly 40, a main shaft 50 and an impeller 60, the motor is used in an integrated pump and gate device, and it drives the impeller 60 Rotate to realize water retention and prevent backflow of outer rivers, and can also pump water from low places to high places to realize strong drainage.

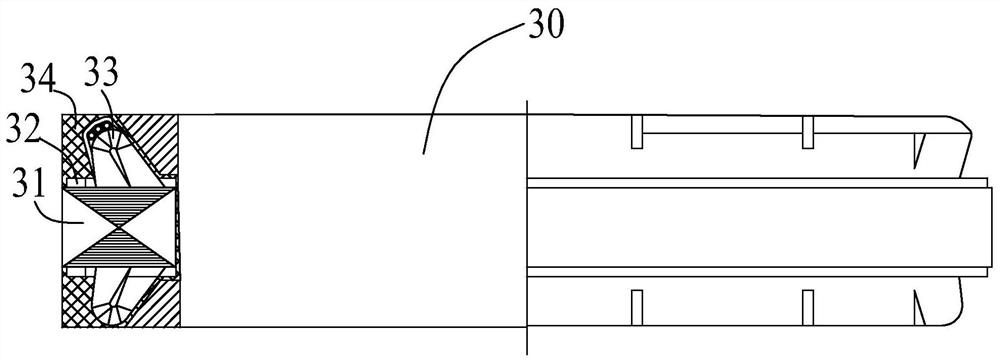

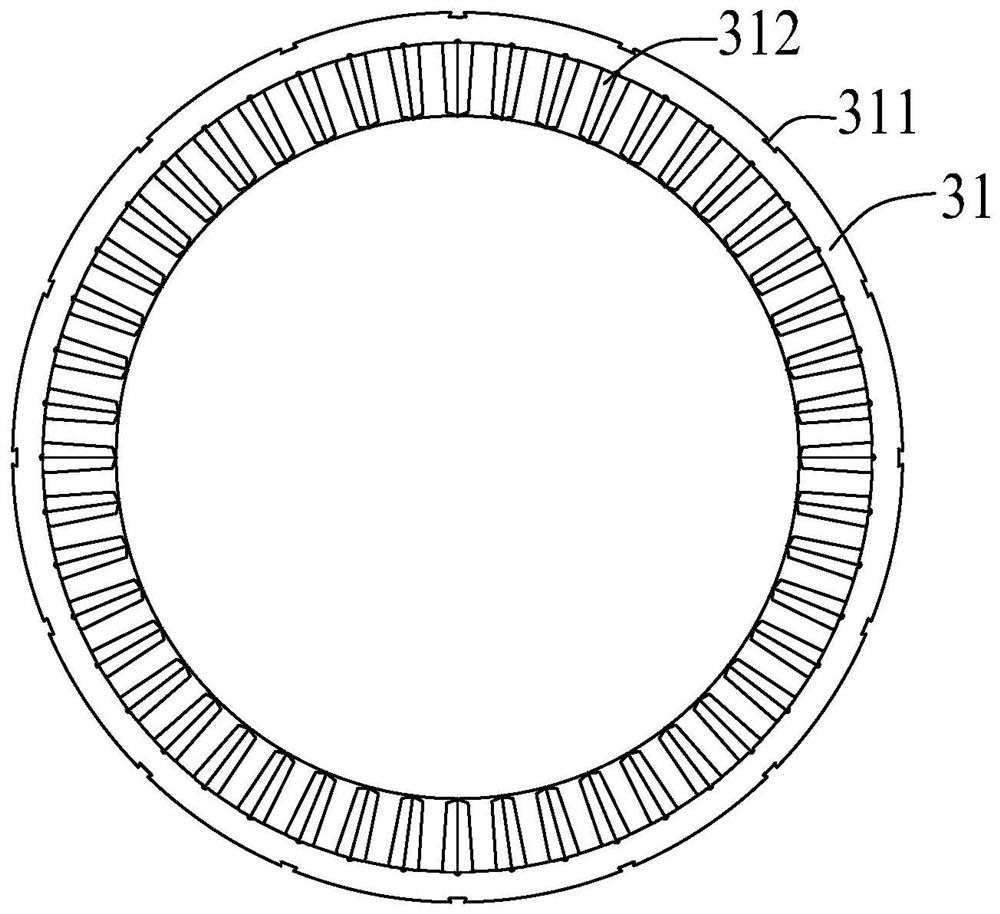

[0022] Such as figure 1 , figure 2 and image 3 As shown, the stator assembly 30 includes a stator punch 31 , a stator pressure ring 32 , a stator coil 33 , a stator potting 34 , a stator end plate 35 and a lead wire 36 . Among them, there are multiple stator punches 31, the number of which is determined according to the design requirements of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com